- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3000*2000*1900mm

-

Year:

-

2021

-

Weight (KG):

-

90000 kg

-

Power (kW):

-

269

-

Applicable Industries:

-

Shredder

-

Blades material:

-

Imported alloy blade

-

Fixed blade:

-

4pcs

-

Power(W):

-

4-30*2kw

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuxi

-

Model Number:

-

YX-1000

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3000*2000*1900mm

-

Year:

-

2021

-

Weight (KG):

-

90000 kg

-

Power (kW):

-

269

-

Applicable Industries:

-

Shredder

-

Blades material:

-

Imported alloy blade

-

Fixed blade:

-

4pcs

-

Power(W):

-

4-30*2kw

Configuration Line

|

No.

|

Machine Name

|

Power(kw)

|

||

|

Steel Wire Removal Process

|

|

|

||

|

1

|

Tire Steel Wire Drawing Machine

|

11

|

||

|

Rubber Block Process

|

|

|

||

|

2

|

Whole Tire Shredder

|

45*2

|

||

|

Rubber Granular Process

|

|

|

||

|

3

|

Separate Steel Wire Machine

|

45

|

||

|

4

|

Rubber Granular

|

37

|

||

|

Rubber Grinding Process

|

|

|

||

|

5

|

Grinder Machine

|

50

|

||

|

Dust Removal Process

|

|

|

||

|

6

|

Magnetic Separator

|

0.75

|

||

|

7

|

Fiber separator

|

|

||

|

8

|

Dust removal equipment

|

5.5

|

||

Products Description

Brief Introduction

This machine is specialized in recycling scrap rubber or scrap tires.

It is suitable for the truck tires, car radial tires, inner tubes, rubber-soled shoes as well as other scrap rubber products that compliance with feeding size.

It is of help to waste material recycling industry The machine adopts the whole base without anchor bolts, easy to install.

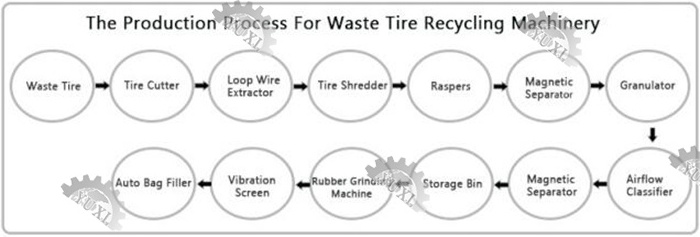

Working Process

1.

Conveyor

-Transport the tire to the shredder;

2.

Double shaft shredder

---Shears the tire into 5-10 cm blocks;

3.

Recirculation system

---To control the size of shreds going to the raspers;

4. Raspers -Reduce the shreds into 15-20 mm chips and liberates steel from the rubber;

4. Raspers -Reduce the shreds into 15-20 mm chips and liberates steel from the rubber;

5.

Over belt magnet

--Separation of liberated steel from the rubber chips;

6.

Vibratory feeder

--Transports the rubber chips;

7. Granulator --Size reduction of the chips to 1-4 mm granules and liberates the textile fraction to air flow separation.

8. Vibratory screen -Sorts the granules by size and removes the majority of textile;

7. Granulator --Size reduction of the chips to 1-4 mm granules and liberates the textile fraction to air flow separation.

8. Vibratory screen -Sorts the granules by size and removes the majority of textile;

9.

Classifer

-Removal of remaining textile;

10.

Drum magnet

-Removal of remaining steel fines;

11. Central de-dusting unit --Remove dust and fines from the system and filter the air before returning it to the atmosphere.

11. Central de-dusting unit --Remove dust and fines from the system and filter the air before returning it to the atmosphere.

Details Images

Automatic Steel Wire Remover

It is the first step to process the tires,it is mainly used for removing the wire loop in the tire bead. The whole tires could be directly put onto this machine to remove the steel wire. Full automatic operating.

Tire Shredder

Waste tire less than 1200mm and rubber materials can be crushed into 50*50 mm block.

The machine consists of rack,cavity, motor, hydraulic coupling, reducer, a group of moving blades, two sets of blades, screen, hydraulic system.

Steel Wire Separator

The basic principle of the motor driven, limited torque coupling driven by reducer, the power and the fixed knife to form the

shear potential, the material through the screen to achieve the specifications of the pellet.

shear potential, the material through the screen to achieve the specifications of the pellet.

Rubber Milling Machine

It is a device that pulverizes 2-6 mm pure rubber particles into 40-200 mesh fine rubber powder at normal temperature.

Technical Parameter

|

Raw Material

|

Raw Material

|

|

Feeding Size

|

1200mm diameter

|

|

Capacity

|

800-1000KG per hour

|

|

Discharge Size

|

0.5mm rubber granulates

|

|

Control Method

|

Automatic

|

|

Size of Equipment

|

500sqm

|

Application

Raw materials

Waste tires, rubber soles, waste pipes, rubber conveyor belts and other waste rubber products, of which waste tires

are the most.

are the most.

What Is The Application of Used Tires?

Recycling of used tires after smashing has become a new industry hotspot and development trend.

The following product applications are for your reference

1.8-20 mesh, mainly used for runways, road cushions, sports pavements, etc.

2.30-40 mesh, mainly used for

reclaimed rubber, paving, producing rubber sheets

reclaimed rubber, paving, producing rubber sheets

3.40-60 mesh, mainly used for rubber rubber filling, plastic modification

4.60-80 mesh, mainly used in automobile tires, rubber products, building materials

Related Product

Why Choose Us

●Pr-sale Service:

24 hours On-line problems discussing & Professional solutions provided & Documents needed preparation

●On-sale Service:

a.All equipment will be assembled into production line before it leaves the factory to simulate actual conditions of use for testing

to ensure production capacity and product quality.

b.We sincerely invite customers to visit our facilities and receive relevant operation and maintenance training.

●After-sale service:

a.Packing list & Commercial Invoice& Bill of Lading Documents provided.

b.Engineers abroad installation service. Debugging & Training customer workers to maintenance,check failure,replace spare parts.

Hot Searches