- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ODMT

-

Model Number:

-

MGS

-

Usage:

-

High Temperature Testing

-

Keyword:

-

air driven gas booster system

-

Color:

-

White

-

Type:

-

MGS

-

Product name:

-

pneumatic gas pressure test machine

-

Main accessories:

-

air driven gas booster pump

-

Certificate:

-

CE Certificate

-

Material:

-

Stainless Steel

-

Function:

-

safety

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Pneumatic

-

Place of Origin:

-

Shandong, China, China

-

Brand Name:

-

ODMT

-

Model Number:

-

MGS

-

Usage:

-

High Temperature Testing

-

Keyword:

-

air driven gas booster system

-

Color:

-

White

-

Type:

-

MGS

-

Product name:

-

pneumatic gas pressure test machine

-

Main accessories:

-

air driven gas booster pump

-

Certificate:

-

CE Certificate

-

Material:

-

Stainless Steel

-

Function:

-

safety

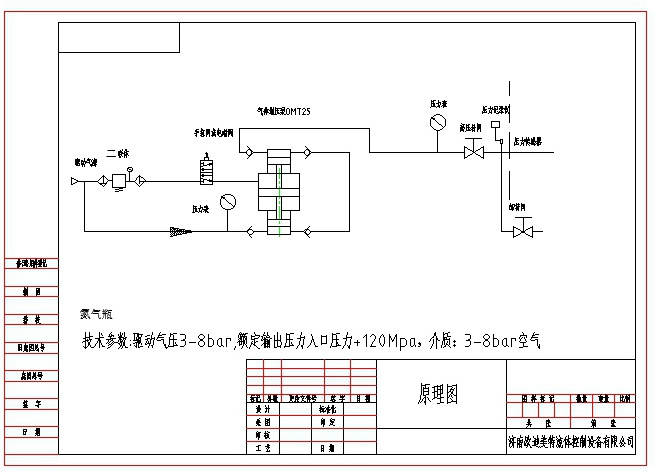

Introduction

MGS series gas boost er system is a new type of gas boost er machine developed by our company based on the working principle of pneumatic pressure testing device imported from abroad and combined with the actual situation in China.The gas booster pump is produced by our company with the introduction of German technology. It is suitable for gas boost er by manufacturers, and is also suitable for use as a high pressure gas pressure source for scientific research and testing institutions.

Function introduction :

Using a pneumatic booster system, pressurize the low pressure gas to the required pressure through the built-in gas drive gas booster pump;

The test stand is equipped with a silencer to avoid excessive noise when the gas is unloaded at the end of the test.

The output pressure can be set through PLC. When the set pressure is reached, it will automatically stop and enter the pressure holding state. If it is lower than the set lower pressure limit, the gas booster pump will start automatically.

Equipment performance parameters

|

Booster Medium |

2- 10 bar Air |

|

Drive pressure |

2- 10 bar |

|

Maximum output pressure |

25 MPa |

|

Maximum flow |

154L/min(inlet pressure:10bar) |

|

Medium temperature |

Normal temperature |

|

Ambient temperature |

Normal temperature |

|

Control loop |

1 |

|

control method |

Manual operation |

Test bench structure

|

Mainly part of machine |

Detailed composition |

Function description |

|

Booster system |

3~10bar compressed air source, two-unit, hand valve, gas booster pump, high pressure needle valve |

The gas source is provided by the user. |

|

Test cabinet (two types) |

One frame structure is welded for ordinary carbon steel profiles, and the other is aluminum alloy frame. |

Surface anti-rust and spray decoration treatment |

|

Drive gas source treatment |

Drive the gas line to the front end of the booster pump and add a filter to the rear end of the union to filter the drive gas. |

|

|

measuring system |

Pressure gauge |

Data measurement for pressure |

|

1. The test bench adopts the box-type overall structure, the power station is integrated, no external leakage, and the appearance is neat and beautiful; 2. All pipelines in the test bench are sealed with high reliability to prevent leakage. |

||

Accessories

|

Name |

Note |

|

OMT25 Air driven gas booster pump |

Booster pump seal is imported |

|

High pressure needle valve |

ODMT/2 sets |

|

Hand valve |

Shanghai Xinyi |

|

Diad |

FESTO(Germany) |

|

Low pressure gauge |

0-1MPa drive gas pressure gauge |

|

High pressure gauge YN100-100 |

0-100MPa, pressure gauge after boosting |

|

Pipeline, high-pressure gas tank connector, box |

High pressure stainless steel pipe joint, aluminum alloy box |

|

PLC control system |

Drawing of Machine for reference.