- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ROCA

-

Model Number:

-

RC-FH4

-

Grade:

-

M3,M4,M5,M6,M8

-

Color:

-

Silvery

-

Application:

-

Connection,Fastening

-

Quality Control:

-

100% quality inspection

-

Sample service:

-

Available

-

OEM Service:

-

Available

-

Certificate:

-

ISO9001:2015, Testing Report & RoHS

-

MOQ:

-

Please contact us

Quick Details

-

Finish:

-

Washing

-

Material:

-

Stainless steel

-

Measurement system:

-

Metric

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ROCA

-

Model Number:

-

RC-FH4

-

Grade:

-

M3,M4,M5,M6,M8

-

Color:

-

Silvery

-

Application:

-

Connection,Fastening

-

Quality Control:

-

100% quality inspection

-

Sample service:

-

Available

-

OEM Service:

-

Available

-

Certificate:

-

ISO9001:2015, Testing Report & RoHS

-

MOQ:

-

Please contact us

Product Description

|

Brand

|

ROCA

|

Category

|

Self-Cinching Screws

|

|

Material

|

410 Stainless Iron

|

Finish

|

Washing

|

|

Standard

|

Metric

|

MOQ

|

1000 PCS

|

|

Installation

|

Press Riveting

|

Package

|

Plastic Bag+Carton+Pallet

|

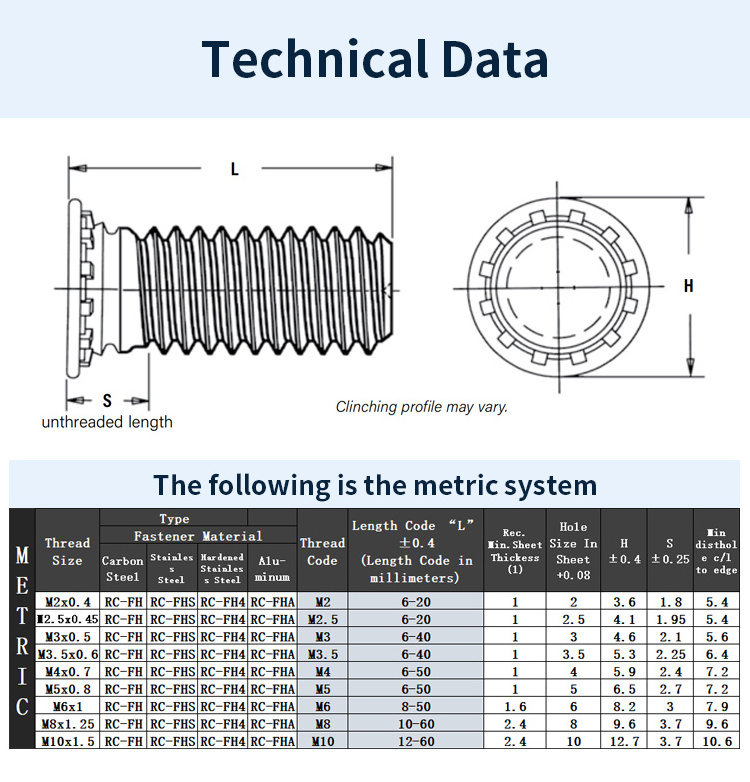

Technical Data

1.To avoid the plate deformation and optimize the product performance, when selecting products, the distance from the center of the selected product hole to the edge of the mounting plate should be as close to or higher than the standard value as possible.

2.The diameter of the punching hole corresponding to the mounting hole shall be controlled within +.011"/.025mm. The punching hole must be kept sharp, and the installation direction of the fastener should be consistent with the that of the punching hole.

3. An appropriate mouth position code shall be selected according to the thickness of the plate, and the nut with high mouth position will be prior- itized if it is possible.

✉️Please contact us for more performance data!

Material Selection

Testing Devices

Production Process

Related Products

Hot Searches