- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customer Requirement

-

Weight:

-

8000 KG

-

Application:

-

placer gold processing

-

Capacity:

-

10-15t/h

-

Recovery rate:

-

90-99%

-

Installation:

-

Under Guidance

-

Test:

-

Client's Sample Testing

-

Keywords:

-

Placer Gold Ore Processing Set Customized Placer Gold Washing Plant

-

Product name:

-

Placer gold washing plant

-

Advantage:

-

High Separation Efficiency

-

Usage:

-

Gold Mining Plant

-

Main products:

-

trommel screen/rotary scrubber/jig machine/vibrating sluice etc.

Quick Details

-

Production Capacity:

-

96%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

YEES

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customer Requirement

-

Weight:

-

8000 KG

-

Application:

-

placer gold processing

-

Capacity:

-

10-15t/h

-

Recovery rate:

-

90-99%

-

Installation:

-

Under Guidance

-

Test:

-

Client's Sample Testing

-

Keywords:

-

Placer Gold Ore Processing Set Customized Placer Gold Washing Plant

-

Product name:

-

Placer gold washing plant

-

Advantage:

-

High Separation Efficiency

-

Usage:

-

Gold Mining Plant

-

Main products:

-

trommel screen/rotary scrubber/jig machine/vibrating sluice etc.

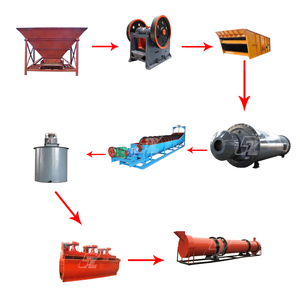

10T/H Small Scale Placer Gold Ore Processing Set Customized Placer Gold Washing Plant

Product Description

The separation principle of alluvial gold is to use gravity separation to recover the most of gold and its associated heavy minerals from the raw ore first, and then use gravity separation, flotation, amalgamation, magnetic separation, electric separation and other combined actions to separate gold and heavy minerals from each other to achieve the purpose of comprehensive recovery. The placer gold mining methods is usually divided into three operations:

(1) Washing operations

The cemented ore sand is separated by water immersion, washing and mechanical agitation, and the gravel, sand and clay are separated, and the clay and gold particles adhered on the gravel are cleaned. The ore washing operation includes three processes: crushing, screening and desliming.

The cemented ore sand is separated by water immersion, washing and mechanical agitation, and the gravel, sand and clay are separated, and the clay and gold particles adhered on the gravel are cleaned. The ore washing operation includes three processes: crushing, screening and desliming.

(2) Rough separation

According to the characteristics of the mine can be divided into these modes: fixed sluice - shaking table process; fixed or vibrating sluice-jig machine-shaking table process; multi-stage jig machine-shaking table process; centrifugal concentrator – shaking table process.

According to the characteristics of the mine can be divided into these modes: fixed sluice - shaking table process; fixed or vibrating sluice-jig machine-shaking table process; multi-stage jig machine-shaking table process; centrifugal concentrator – shaking table process.

(3) Cleaning separation

Heavy sand and mercury are mixed in a mercury mixing cylinder, heavy sand is not adsorbed by mercury and is removed, but the gold will be adsorbed into the mercury.

Heavy sand and mercury are mixed in a mercury mixing cylinder, heavy sand is not adsorbed by mercury and is removed, but the gold will be adsorbed into the mercury.

Advantages

Application

Our Factory

Our Workshop

Our Services

Hot Searches