- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Klifting

-

Model Number:

-

KS35/170

-

Length:

-

6m per piece or customized

-

Application places:

-

Steel mills, Coking plants, Gas works, Cement industries, etc

-

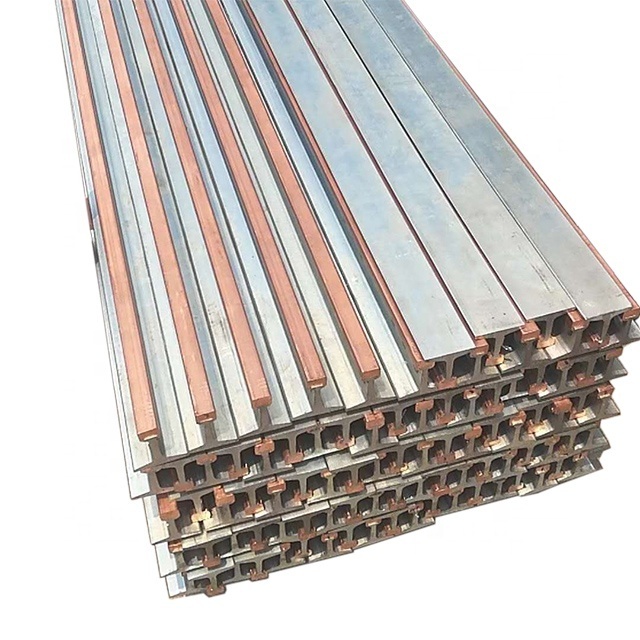

Conductor Material:

-

Copper and steel

-

Working Environment:

-

High temperature, corrosive, high humidity atmospheres

Quick Details

-

Material:

-

Copper and steel

-

Rated Current:

-

200-1500A

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Klifting

-

Model Number:

-

KS35/170

-

Length:

-

6m per piece or customized

-

Application places:

-

Steel mills, Coking plants, Gas works, Cement industries, etc

-

Conductor Material:

-

Copper and steel

-

Working Environment:

-

High temperature, corrosive, high humidity atmospheres

Product Description

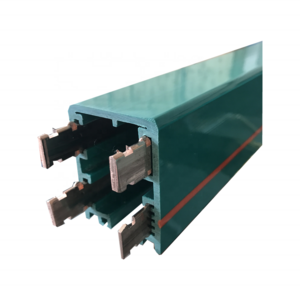

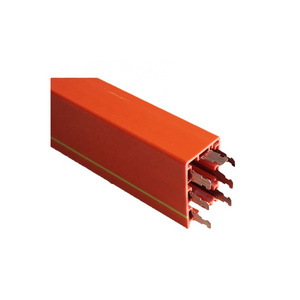

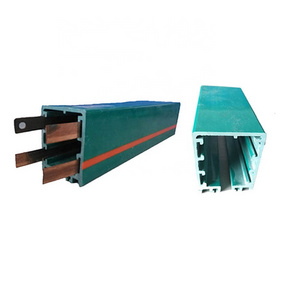

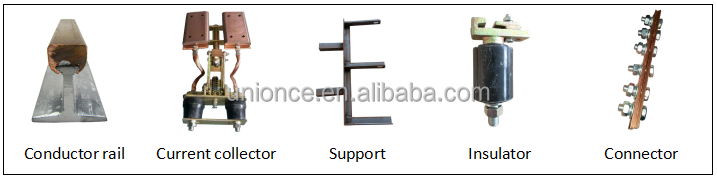

Klifting Electrical Copperhead Steel Conductor Bar for Crane Power Rail

Applications

1. Steel mills, Coking plants, Gas works, Cement industries, Ship yards and Dockside enterprises.

2. Fibreglass-Copperhead Rails are preferably used for applica- tions in corrosive atmospheres and in locations with high humidity.

3. Aluminium-Copperhead Rails are very economical due to the light weight of the Aluminium and its high conductivity.

4. Solid-Copper Rails are recommended for heavy duty current rating and for humid locations.

Advantages

1. Copperhead Rails ensure an efficient and continuous contact.

2. There is no sparking.

3. The easy maintenance is a proven low factor.

4. No losses due to interruption of service, no downtime.

5. Negligible wear - almost unlimited life of conductors.

6. Much lower resistance between copperhead and carbon pick- up shoe.

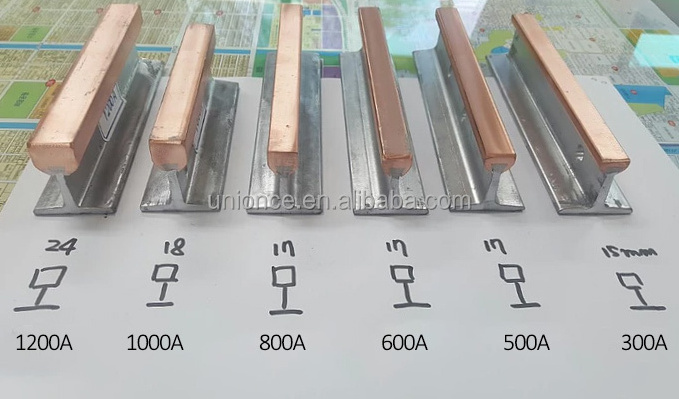

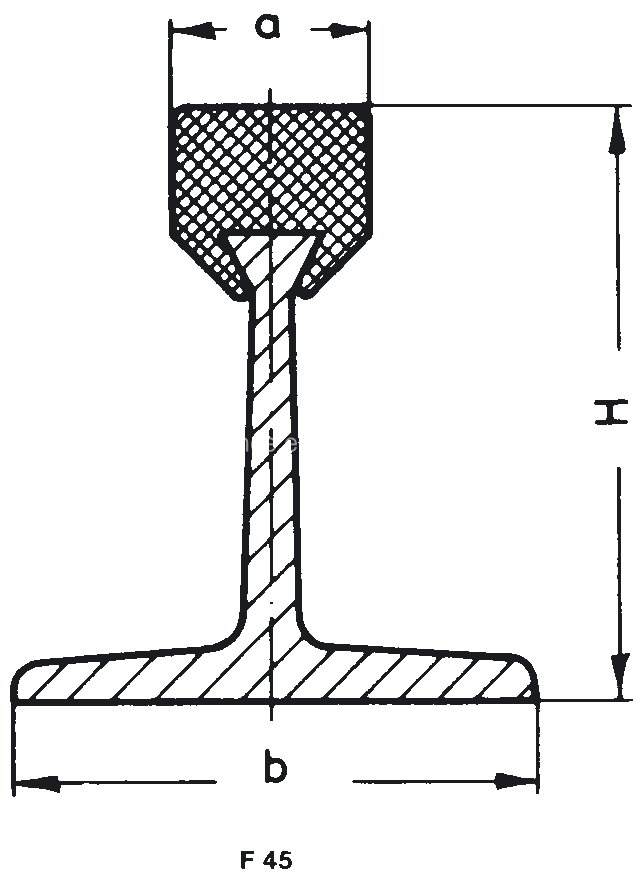

Copperhead Conductor Rail

|

Type

|

Steel cross section

mm2 |

Copper cross section

mm2 |

a

mm |

b

mm |

H

mm |

Weight

Kg/m |

Max continuous mm2

|

Part No. |

|

KS 35/80-6

|

230

|

80

|

15

|

35

|

34

|

15.2

|

340

|

200015

|

|

KS 35/85-6

|

230

|

85

|

15

|

35

|

34.5

|

15.5

|

457

|

200025

|

|

KS 35/90-6

|

230

|

90

|

15

|

35

|

35

|

15.8

|

372

|

200035

|

|

KS 35/100-6

|

230

|

100

|

15

|

35

|

36.5

|

16.34

|

402

|

200045

|

|

KS 35/130-6

|

230

|

130

|

18

|

35

|

36

|

17.9

|

492

|

200055

|

|

KS 35/170-6

|

230

|

170

|

18

|

35

|

38

|

20.0

|

612

|

200065

|

|

KS 35/200-6

|

230

|

200

|

18

|

35

|

40

|

21.6

|

700

|

200075

|

|

Type

|

Steel cross section

mm2 |

Copper cross section

mm2 |

a

mm |

b

mm |

H

mm |

Weight

Kg/m |

Max continuous mm2

|

Part No. |

|

KS 50/220-6

|

460

|

220

|

20

|

50

|

50

|

35.7

|

850

|

200115

|

|

KS 50/270-6

|

460

|

270

|

20

|

50

|

53

|

38.4

|

1000

|

200225

|

|

KS 50/300-6

|

460

|

300

|

20

|

50

|

54

|

40.0

|

1100

|

200335

|

|

KS 50/350-6

|

460

|

350

|

30

|

50

|

61

|

42.5

|

1200

|

200445

|

|

KS 50/370-6

|

460

|

370

|

30

|

50

|

62

|

43.5

|

1300

|

200555

|

|

KS 50/400-6

|

460

|

400

|

30

|

50

|

63

|

45.3

|

1400

|

200565

|

For more details, welcome to contact us to get catalogue and price list.

Packing & Delivery

Iron frame for conductor rails and MDF wooden case for parts

Successful Project

Hot Searches