- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JINLAI

-

Weight (KG):

-

21

-

Voltage:

-

Single Phase 220V 50/60HZ

-

Current:

-

37A

-

Rated Capacity:

-

4500UF

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

460*200*350mm

-

Use:

-

Alloy carbide tools welding

-

Max Current:

-

40A

-

Oscillation Frequency:

-

30-100KHz

-

Advantage:

-

Portable

-

Application:

-

Alloy carbide tools welding

-

Type:

-

High Frequency Welding

-

Power:

-

12kw

-

Key Parts:

-

IGBT and Power Tube

-

Level:

-

High Automatic

-

Key:

-

Manual Induction Heating Brazing Welding Machine for Cemented Carbide

-

Import key:

-

Induction Brazing Machine

Quick Details

-

Applicable Industries:

-

Diamond tools, Stone Factory

-

Marketing Type:

-

New Product 2023

-

Core Components:

-

IGBT, Power tube

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JINLAI

-

Weight (KG):

-

21

-

Voltage:

-

Single Phase 220V 50/60HZ

-

Current:

-

37A

-

Rated Capacity:

-

4500UF

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

460*200*350mm

-

Use:

-

Alloy carbide tools welding

-

Max Current:

-

40A

-

Oscillation Frequency:

-

30-100KHz

-

Advantage:

-

Portable

-

Application:

-

Alloy carbide tools welding

-

Type:

-

High Frequency Welding

-

Power:

-

12kw

-

Key Parts:

-

IGBT and Power Tube

-

Level:

-

High Automatic

-

Key:

-

Manual Induction Heating Brazing Welding Machine for Cemented Carbide

-

Import key:

-

Induction Brazing Machine

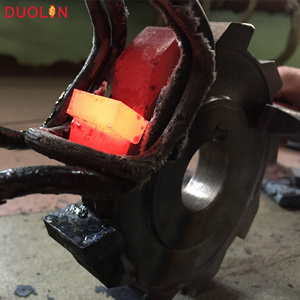

Manual Rack Induction Heating Brazing Welding Machine for Cemented Carbide

Products Features:

1. Fast heating speed, 3-5 seconds for 1 piece of segments of saw blades of medium size;

2. working in 24 hours with 100% full load.

2. working in 24 hours with 100% full load.

Product Description

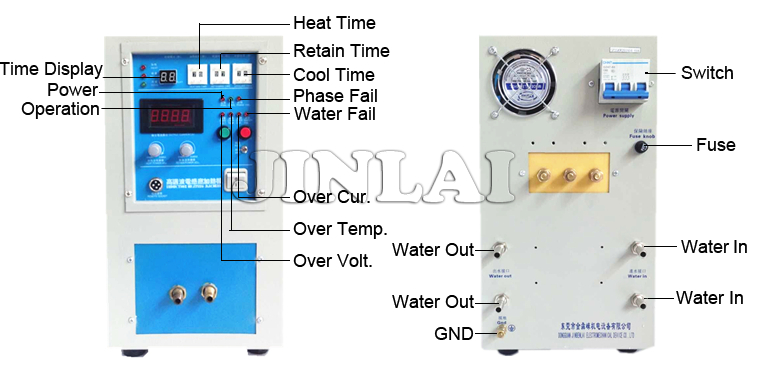

Main Characteristics

* 1. Adoping MOSFGT and IGBT inverting device, tracking frequency automatically.

* 2. High frequency, heated quickly, its power consumption is only 20%~30% of eletronic tube induction heating machine and other heating style.

* 3. Security and reliability, the equipments have the secure voltage and it's secure to operate.

* 4. Manual, automatic regulating automatically, it can protect itself from over voltage, over current, lack of water, phase

fail, over hot, etc.

* 5. It has no open-fire, noise and pollution, be suit for the environmental protection and fire, improve the image of the

company.

* 6. Recommend usage: Weld, forging, hot cooperate, melting, quenching, anneat etc.

* 2. High frequency, heated quickly, its power consumption is only 20%~30% of eletronic tube induction heating machine and other heating style.

* 3. Security and reliability, the equipments have the secure voltage and it's secure to operate.

* 4. Manual, automatic regulating automatically, it can protect itself from over voltage, over current, lack of water, phase

fail, over hot, etc.

* 5. It has no open-fire, noise and pollution, be suit for the environmental protection and fire, improve the image of the

company.

* 6. Recommend usage: Weld, forging, hot cooperate, melting, quenching, anneat etc.

Specification

|

Model

|

JLJP-150

|

|

Input Power

|

Single Phase 180-250V 50/60Hz

|

|

Oscillate Power Max

|

20kw

|

|

Max Input Current

|

1500A

|

|

Max Input Power

|

12kw

|

|

Oscillate Frequency

|

30-100KHz

|

|

Cooling Water

|

≥0.2mpa flow 2-5L/min

|

|

Machine Power Cable Length

|

2-6M

|

|

Duty Cycle

|

100% 40℃

|

|

Size

|

460*200*350mm

|

|

Weight

|

22kg

|

Application Showcase

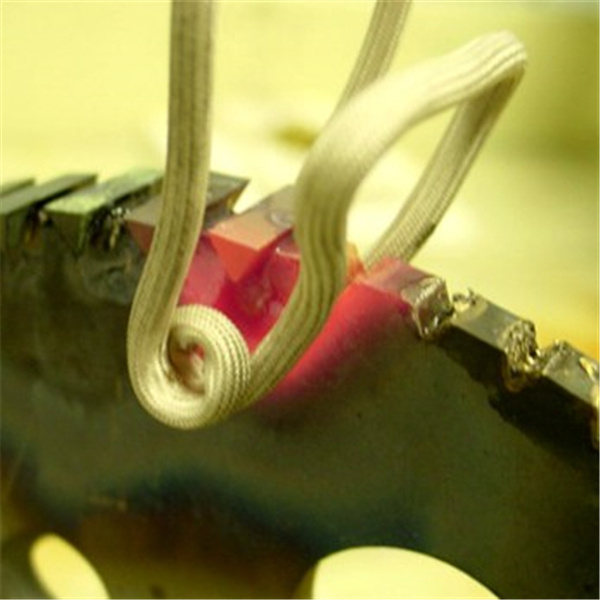

Application: Induction Heating Machine for Brazing Welding Cemented Carbide

Applications

* 1. Metal tube welding: such as copper tube, steel tube, and aluminum tube’s butt welding, plug welding and welding sets.

* 2. Alloy cutter welding: such as alloy turning, milling cutter, planer, saw blades, reamer, boring knife.

* 3. Carbide saw blade welding: diamond saw blade welding, marble saw blade welding,woodworking saw blade welding, cut grass piece of welding, cut aluminum welding,

* 4. Metal welding: such as: towel rack, soap nets, towel holder, auto-accessories,motor accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

* 5. make machine according to customers' actual working situation.

* 2. Alloy cutter welding: such as alloy turning, milling cutter, planer, saw blades, reamer, boring knife.

* 3. Carbide saw blade welding: diamond saw blade welding, marble saw blade welding,woodworking saw blade welding, cut grass piece of welding, cut aluminum welding,

* 4. Metal welding: such as: towel rack, soap nets, towel holder, auto-accessories,motor accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

* 5. make machine according to customers' actual working situation.

Packing & Delivery

The machine will be packed in plywood case.

Hot Searches