- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BRD

-

Model Number:

-

PU Sandwich Panel

-

Normal thickness:

-

50mm, 75mm, 100mm

-

Normal Width:

-

1000mm

-

Length:

-

according to your request, less than 11.8m

-

Structure:

-

PPGI + pu +PPGI

-

Normal Color:

-

red, blue, white-grey,as customized

-

Core material:

-

pu foam

-

Advantage:

-

Heat Insulaton , fire rated

-

Usage:

-

Construction Insulation

-

Density:

-

40 - 42 kg/m3

-

Flame resistance:

-

Grade B

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Villa

-

Design Style:

-

Modern

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BRD

-

Model Number:

-

PU Sandwich Panel

-

Normal thickness:

-

50mm, 75mm, 100mm

-

Normal Width:

-

1000mm

-

Length:

-

according to your request, less than 11.8m

-

Structure:

-

PPGI + pu +PPGI

-

Normal Color:

-

red, blue, white-grey,as customized

-

Core material:

-

pu foam

-

Advantage:

-

Heat Insulaton , fire rated

-

Usage:

-

Construction Insulation

-

Density:

-

40 - 42 kg/m3

-

Flame resistance:

-

Grade B

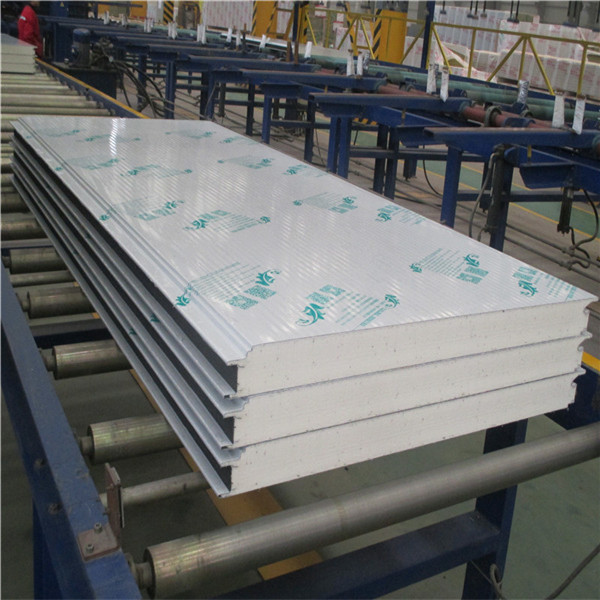

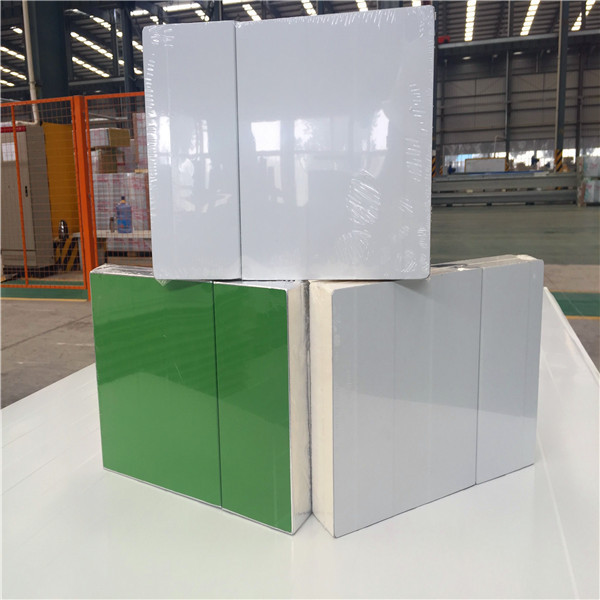

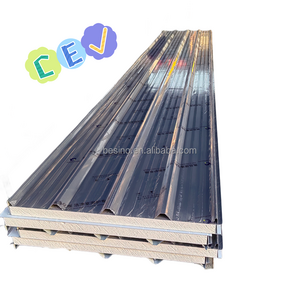

BRD pu sandwich panel can be different types for customer choice, like Mirror, Samll wave, Concave, Ripple.

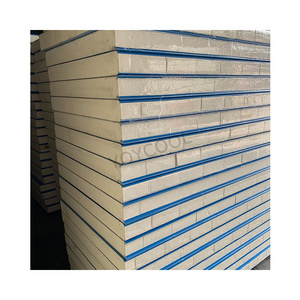

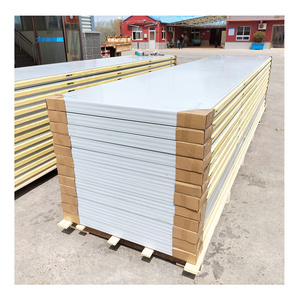

The PU sandwich wall panel is widely used to the large-sized factory buildings, warehouses, cold storage, exhibition halls, kiosks, gymnasiums, etc. The Polyurethane wall panel is generally divided into three types: Small seamless corrugated wall panels, The slotted corrugated wall panels, The concave wall panels and Mirror panels. There are two ways for wall panel connections: Buried connection and pluggable connection. We could not find any nails or other metal tools. These kinds of connections make the product look more beautiful, and the wall seems much smooth. The core material can be divided into the polyurethane, the polyurethane sealing sandwich rock wool panel, the polyurethane edge glass wool panel.

Features

1. Connection: dark nail connection, surface exposed screws, graceful building wall.

2. The strength, stiffness, stability, impact resistance, excellent shock resistance, corrosion resistance, resistance to atmospheric resistance.

3. The insulation, insulation, excellent noise performance. In the plate can effectively solve the cold bridge insulation performance, reduce the costs of the building air conditioning system.

4. High degree of prefab little affected by the bad weather during the construction, and therefore the more traditional method of construction, the construction period can be shortened by more than 40%.

5. Class B fire performance, maximum use temperature of 180 ℃ .

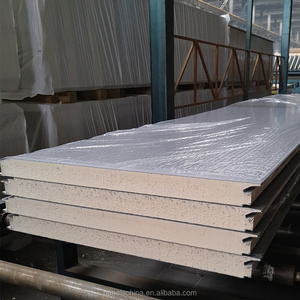

| Panel Material | Metal |

| Brand | BRD |

| Place of Origin | China |

| Density | 40 – 42 kg/m 3 |

| Length | Customized as long as it can be transported away |

| Effective Width | 1,000mm |

| Core Thickness | 50mm, 75mm, 100mm |

| Thickness of Surface Metal | 0.4 - 0.7mm |

| Features | Sound proof, fire proof, water proof |

| Certificates | CE, ISO14001, ISO9001 |

| Surface Appearance | Small wave, flat, embossment, big rib, etc. |

| Color | Customized |

| Fire Proof Rate | B |

Our wall panels are generally divided into four categories:

(1) Seamless small corrugated wall panel

(2) The concave wall panel

(3) Slotted wall panel

(4) Mirror panel

Each wall has its unique properties and features, customers can choose the products they want style according to your requirements.

1.Super Flame Retardation

The coefficient of thermal conductivity is 0.023w/(m•k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building absorbing heat and brings enormous economic benefits.

2.Economical

Great flame retardation and the complete removal of cold bridges (during the rafter installation), do help reduce heating bills.

3.Easy and Quick Insulation

Compared with traditional thermal insulation methods, BRD use less material while the installation process is less time-consuming and labor-demanding leading to lower building costs.

Low thermal conductivity of pu sandwich panels with excellent thermal insulation properties, can greatly reduce the thickness of periphery of the building structure, which effectively increasing the interior area of the building.

1, First of all, it must carry on the construction preparation before installation, include personnel, materials, etc. All will be well prepared.

2, Before the installation of polyurethane wall panel, it should check whether the verticality and levelness of metope purlin installation requirements, wall frame column vertical degree meets the requirement.

3, Before installation polyurethane wall panel, it should first mounting plate bottom water retaining plate and the bottom of the window to block water board, water retaining plate and wall frame beam connection with self tapping screw fixation.

4, Polyurethane wall panel links with ground.

Lateral links: fixed polyurethane sandwich panel with the ground at the other end of the round hole with steel frame fixed, connection between the two plate mouth involution, if occurrence crack of the connectors available heat preservation to fill.

Vertical links: the gap between plates, using the dedicated button concave groove in the fixed polyurethane wall panel.

The sales net is targeted at those countries and places where are eager for sandwich panels. Till now, BRD sandwich panels have been exported to over 21 countries and places and more and more customers have made twice or third order, which proves BRD is worth of your reliance.