- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

1 - 25

-

Marketing Type:

-

New Product 2024

-

Coil Weight (T):

-

3 T

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BoBo

-

Voltage:

-

380V 50HZ 3 phase

-

Rated Power:

-

15kw

-

Dimension(L*W*H):

-

2100*1100*1800 mm

-

Weight:

-

3, 2500 KG

-

Year:

-

2024

-

Motor Power:

-

15KW

-

After-sales Service Provided:

-

Overseas Third-party Support

-

Maximum outer diameter of finished roll:

-

500 mm

-

Coiling mode:

-

Longitudinal double coiling

-

Cutting precision:

-

±0.02mm

Quick Details

-

Cutting Width (mm):

-

1 - 60000 mm

-

Material Thickness(mm):

-

0.2 - 4 mm

-

Cutting Speed(m/min):

-

1 - 50 mm

-

No. of Slitting Lines:

-

1 - 25

-

Marketing Type:

-

New Product 2024

-

Coil Weight (T):

-

3 T

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BoBo

-

Voltage:

-

380V 50HZ 3 phase

-

Rated Power:

-

15kw

-

Dimension(L*W*H):

-

2100*1100*1800 mm

-

Weight:

-

3, 2500 KG

-

Year:

-

2024

-

Motor Power:

-

15KW

-

After-sales Service Provided:

-

Overseas Third-party Support

-

Maximum outer diameter of finished roll:

-

500 mm

-

Coiling mode:

-

Longitudinal double coiling

-

Cutting precision:

-

±0.02mm

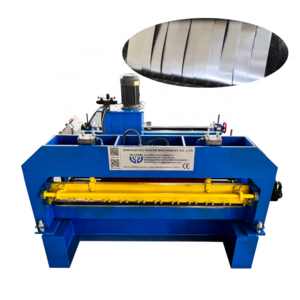

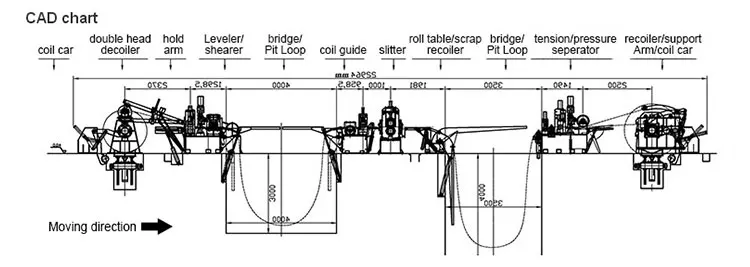

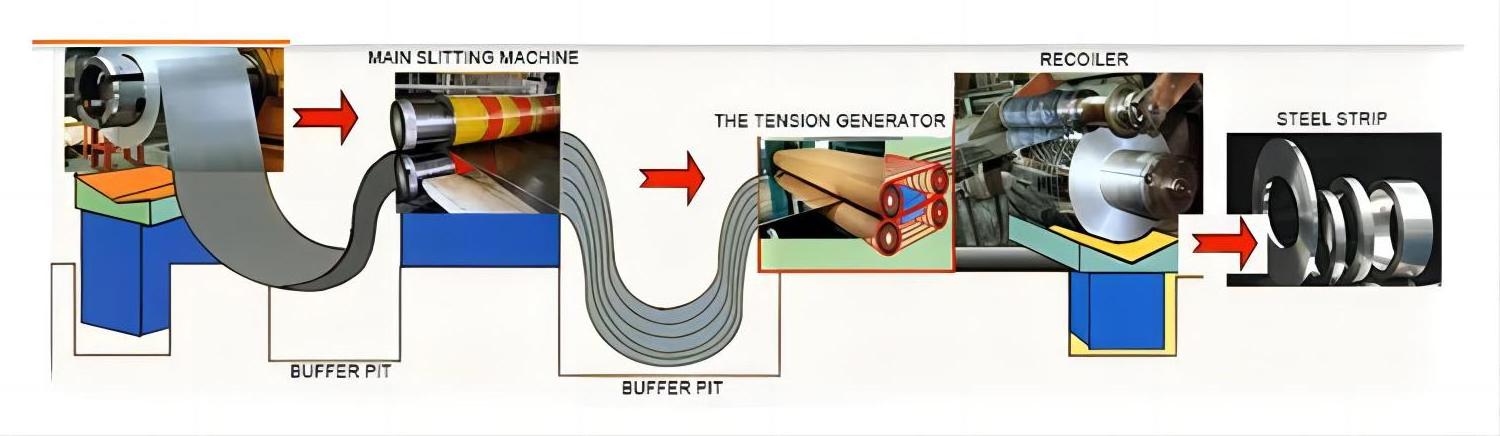

Automation 2x1250 Steel Coil Cold Rolled Steel Galvanized Sheet Metal Mini Slitter Rewinder Steel Coil slitting Line Machine

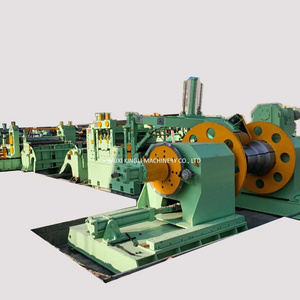

1. Uncoiler

Finish the unwinding of the strip. The unwinder uses passive unwinding. The uncoiler consists of base and reel.

The reel adopts the hydraulic structure of rising and shrinking. The reel has high precision and the range of expansion and

contraction is from Φ280mm to Φ320mm.

The reel adopts the hydraulic structure of rising and shrinking. The reel has high precision and the range of expansion and

contraction is from Φ280mm to Φ320mm.

The uncoiler is equipped with magnetic powder tension device to prevent loose rolls.

2. Disc shear

Function: It is used for slitting the strip material and cutting the strip material into finished width.

2. Disc shear

Function: It is used for slitting the strip material and cutting the strip material into finished width.

Structure and features: The disc shear consists of body part, power part, base and other parts.

The body part mainly includes fixed frame, movable frame, knife shaft device and so on. The movable frame can be The base linear guide can be moved to provide convenience for replacing the knife disk, knife pad and knife row. In order to ensure the shear quality, the knife shaft adopts integral type. The lifting mechanism adopts the motor to drive the upper knife shaft slide up and down, and the fine adjustment of knife depth is manually adjusted. The knife depth fine-tuning is manually adjusted.

The body part mainly includes fixed frame, movable frame, knife shaft device and so on. The movable frame can be The base linear guide can be moved to provide convenience for replacing the knife disk, knife pad and knife row. In order to ensure the shear quality, the knife shaft adopts integral type. The lifting mechanism adopts the motor to drive the upper knife shaft slide up and down, and the fine adjustment of knife depth is manually adjusted. The knife depth fine-tuning is manually adjusted.

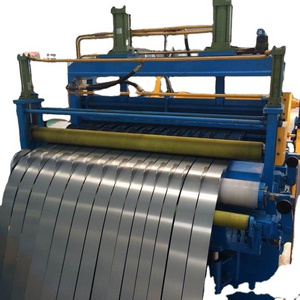

3. Winding device

The winding power unit consists of a motor. Maximum outer diameter of winding: φ500mm

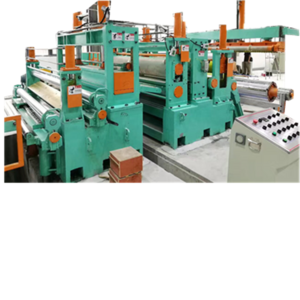

4. Electrical control system

This system adopts frequency conversion speed control to drive the shear motor and winding motor. When the production line is running, the speed of the whole line is set manually by the potentiometer, and according to the situation, the stop button can be pressed at any time to stop the whole line. The electrical control system consists of a control console. The unit uses AC power supply.

The winding power unit consists of a motor. Maximum outer diameter of winding: φ500mm

4. Electrical control system

This system adopts frequency conversion speed control to drive the shear motor and winding motor. When the production line is running, the speed of the whole line is set manually by the potentiometer, and according to the situation, the stop button can be pressed at any time to stop the whole line. The electrical control system consists of a control console. The unit uses AC power supply.

5. Composition and use

The system is equipped with one operating console and one electrical control box. The whole line adopts centralized control.

The system is equipped with one operating console and one electrical control box. The whole line adopts centralized control.

The main operating console has the functions of digital display, high and low speed adjustment, manual feeding, continuous slitting and fault alarm. Other electrical control components are imported or joint venture products of the same grade.

Function: It is used for slitting the strip material and cutting the strip material into finished width.

Structure and features: The disc shear consists of body part, power part, base and other parts.

The body part mainly includes fixed frame, movable frame, knife shaft device and so on. The movable frame can be The base linear guide can be moved to provide convenience for replacing the knife disk, knife pad and knife row. In order to ensure the shear quality, the knife shaft adopts integral type. The lifting mechanism adopts the motor to drive the upper knife shaft slide up and down, and the fine adjustment of knife depth is manually adjusted. The knife depth fine-tuning is manually adjusted.

Structure and features: The disc shear consists of body part, power part, base and other parts.

The body part mainly includes fixed frame, movable frame, knife shaft device and so on. The movable frame can be The base linear guide can be moved to provide convenience for replacing the knife disk, knife pad and knife row. In order to ensure the shear quality, the knife shaft adopts integral type. The lifting mechanism adopts the motor to drive the upper knife shaft slide up and down, and the fine adjustment of knife depth is manually adjusted. The knife depth fine-tuning is manually adjusted.

|

1

|

Material

|

metal sheet and strip

|

|

2

|

Thickness of raw material roll

|

0.1mm~1.0mm

|

|

3

|

width of raw material roll

|

≤450mm

|

|

4

|

Maximum outer diameter of raw material roll

|

Φ1000mm

|

|

5

|

Inner diameter of raw material coil

|

Φ300mm

(range of expansion and contraction: Φ280mm~Φ320mm)

|

|

6

|

Maximum weight of raw material roll

|

2000kg

|

|

7

|

Number of cut strips

|

≤15 strips

|

|

8

|

Cutting precision

|

±0.02mm

|

|

9

|

Shear speed

|

0~80M/min

|

|

10

|

Inner diameter of finished roll

|

Φ80mm

|

|

11

|

Maximum outer diameter of finished roll

|

Φ500mm

|

|

12

|

Disc shear motor

|

7.5kw

|

|

13

|

Coiler power

|

4kw+4kw

|

|

14

|

Total capacity of equipment

|

18 kw

|

|

15

|

Equipment weigh

|

3 T

|

|

16

|

Coiling mode

|

longitudinal double coiling

|

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other

payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other

payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

Hot Searches