- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.27

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1500*900*1350mm

-

Year:

-

2024

-

Power (kW):

-

55

-

Weight (KG):

-

10000 KG

-

Product name:

-

Rubber Open Mixing Mill

-

Roller rotation speed:

-

Set Speed

-

Roller:

-

2 Roller Mixing Mill

-

Roller Pitch(mm):

-

1mm-10mm

-

Motor:

-

55KW

Quick Details

-

Diameter of Roll(mm):

-

450 mm

-

Rotation Speed of Front Roll(rpm):

-

1 - 23.8 rpm

-

Length of Roll(mm):

-

1200 mm

-

Roll Ratio(Front/Back):

-

1:1.27

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1500*900*1350mm

-

Year:

-

2024

-

Power (kW):

-

55

-

Weight (KG):

-

10000 KG

-

Product name:

-

Rubber Open Mixing Mill

-

Roller rotation speed:

-

Set Speed

-

Roller:

-

2 Roller Mixing Mill

-

Roller Pitch(mm):

-

1mm-10mm

-

Motor:

-

55KW

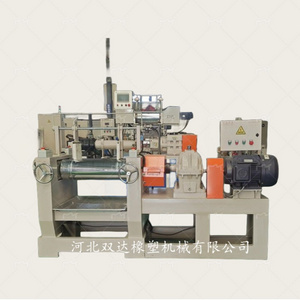

18 inch rubber mixer parameter configuration table

1. Equipment model: YX-XK450

2. Roller diameter: 450mm

3. Roll length: 1200mm

4. Front roller line speed: 23.85r/min

5. Roller speed ratio: 1:1.27

6. One feed: 40-120kg(silicone)

7. Main motor power: 55KW

8. Bearing situation: double front plain bearing

9. Reducer: hard gear surface precision reducer ZSY

series

10. Maximum roll distance: 25mm

11. Power supply: 3 # AC380V

12. Machine weight: ≈10000kg

13. Machine size: ≈4400*1600*1900mm

18 inch rubber mixing machine structure introduction

1. This machine is mainly composed of a body frame. Frame, roller, drive gear and gear reduction. Motor and other components

Agreed. The roller is made of chilled cast iron. The workpiece surface has high hardness and wear resistance after grinding.

The roller is hollow inside and the water system is filled with water. The worm gear reducer is installed next to the machine base

The sides, rollers and frame are arranged on the upper part of the machine to make it compact. Easy to operate.

2. The transmission part of the machine is driven by the hard gear reducer motor located outside the frame, through the transmission gear

Drive the back roller to turn, and then drive the front roller through a pair of speed ratio gears installed on the left end of the roller to make the front and back two

The supporting rollers turn at different speeds in the relative direction.

3. The transmission gear has a closed protective device, and the machine is equipped with an electrical brake device. When an emergency stop is needed,

Press the emergency stop switch, immediately brake, more reliable safety performance.

This machine is designed and manufactured by our company. It is mainly used for mixing equipment of silica gel and rubber, with exquisite structure and safety

Convenient, wide applicability, high efficiency.