- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

300*150*100 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DONGYUE

-

Voltage:

-

380V/440V/415V/220V

-

Dimension(L*W*H):

-

700*400*800MM

-

Weight (KG):

-

900 kg

-

steel standard:

-

GB Q235

-

AC contactor:

-

Shilin/Schneider

-

color:

-

depond on your requirement

-

Main market:

-

Southeast Asia,Africa,South America

-

welding:

-

Carbon dioxide welding

-

block moulds:

-

heat treatment,wire cutting

-

After Warranty Service:

-

Video technical support

Quick Details

-

Type:

-

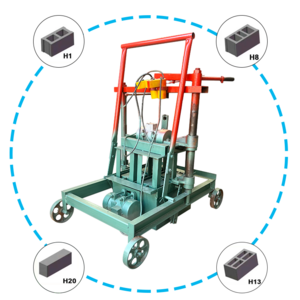

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

1000 pcs/8hours, 800 pcs/8hours, 1920pcs/DAY

-

Brick size:

-

300*150*100 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DONGYUE

-

Voltage:

-

380V/440V/415V/220V

-

Dimension(L*W*H):

-

700*400*800MM

-

Weight (KG):

-

900 kg

-

steel standard:

-

GB Q235

-

AC contactor:

-

Shilin/Schneider

-

color:

-

depond on your requirement

-

Main market:

-

Southeast Asia,Africa,South America

-

welding:

-

Carbon dioxide welding

-

block moulds:

-

heat treatment,wire cutting

-

After Warranty Service:

-

Video technical support

Main Features

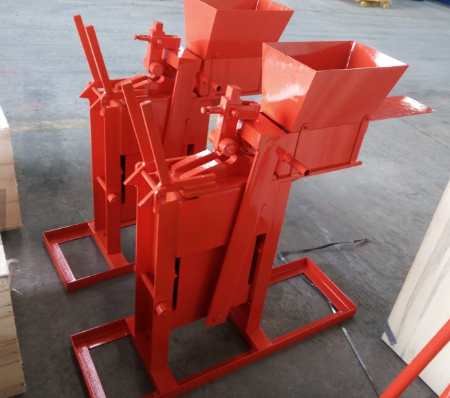

1. Manual interlocking clay brick making machine is cheap and durable, easy to operate and no need power.

2. Clay brick machine is quick in product forming, high in product density and strong in pressing power.

3. This clay brick making machine uses a mixture of soil and cement to make stabilized bricks at a ratio of between 5 and 10% cement to soil, depending on the soil type available.

4. Bricks are interlocking so there is no need for mortar when building.

5. Easy Operation. Hand press concrete /cement brick making machine.

|

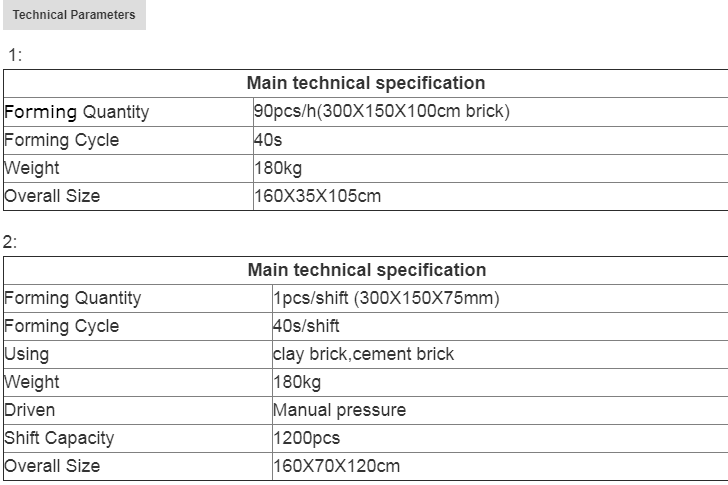

Theoretical Production Capacity and main technical specification

|

|

|

|

|||

It is widely used in buildings, road paving, squares, gardens, landscaping, city constructions etc. By changing different mold, the moveable brick making machine can produce different wall brick, porous brick and cement solid brick, it can meet the brick requirement of small construction engineering, is the best selection of small scale brick factory or mobile brick factory.There are various interlocking clay brick making machine size and shapes for your selection as following. Or you can also tell me your detailed requirement about the final brick.

Advantages of QTS2-40

1. Easy Operation.

This machine can be operated by any workers just by short-time leaning

2 .High-efficiency.

With low consumption of material,every brick can be made in 30-40s,which will ensure a quick production and good quality.

3.Flexibility

. QTS2-40 is with a small body size,so it can cover less land area.Moreover, it can be moved from one to another place easily.

4.Environment-friendly.

This brick machine works without any fuels just under operation of human.

5.Worth for your investment

. Compared with other bigger machines,QTS2-40 can take little cost and return you a good output.

6.Made under strict quallity control

. Each of our machine needs to be tested as a qualified product bfore leaving factory.

Raw material ratio :

Method one :5 % cement +clay

Method two :8 % cement +clay

Method one :10 % cement +clay

Method two :10 % cement +sand +water

*Can produce interlocking bricks ,paver bricks with different sizes ,also other different kind of bricks by changing different mould

Packing & Delivery

Our Service

Pre-Sales

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

Sale

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

After-Sales

1.Warranty period :1 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.