Pressure column for cnc hydraulic guillotine cutters industrial

- Product Details

- {{item.text}}

Quick Details

-

Backgauge Travel (mm):

-

20 - 500 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

RBQLTY

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

3150 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V/415V/440V/400V

-

Dimension(L*W*H):

-

3200x1750x1800

-

Type:

-

Shearing Machines

-

CNC System:

-

E21S servo cnc

-

Stopper adjust range:

-

20-500mm

-

Cutting length:

-

2500mm

-

Function:

-

sheet metal shearing

-

Hydraulic System:

-

German BOSCH Hydraulics

-

Electrical components:

-

Schneider

-

Seal Ring:

-

Japan NOK

-

Internal gear pump:

-

Ameica Sunny

-

Application:

-

Industrial Metal Cutting

Quick Details

-

Max. Cutting Width (mm):

-

2500

-

Max. Cutting Thickness (mm):

-

4 mm

-

Blade Length (mm):

-

2600 mm

-

Backgauge Travel (mm):

-

20 - 500 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

RBQLTY

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

3150 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V/415V/440V/400V

-

Dimension(L*W*H):

-

3200x1750x1800

-

Type:

-

Shearing Machines

-

CNC System:

-

E21S servo cnc

-

Stopper adjust range:

-

20-500mm

-

Cutting length:

-

2500mm

-

Function:

-

sheet metal shearing

-

Hydraulic System:

-

German BOSCH Hydraulics

-

Electrical components:

-

Schneider

-

Seal Ring:

-

Japan NOK

-

Internal gear pump:

-

Ameica Sunny

-

Application:

-

Industrial Metal Cutting

Rbqlty swing beam shear machine iron plate shearing machine

Standard Equipment:

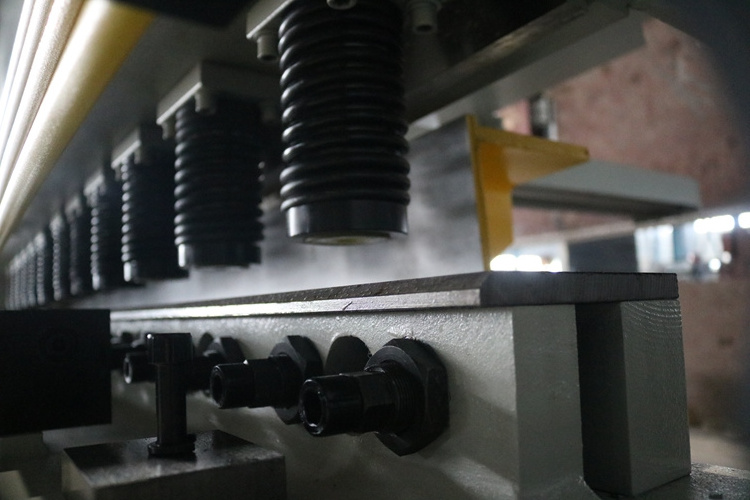

1. Rapid and precise blade clearance adjustment by single handle on the side frame

2. Multi Edge Blades for cutting Aluminium, Mild Steel and Stainless Steel

3. Cutting Line Illumination and wire for shadow line cutting

4. Counter of Strokes, Cutting Length Adjustment

5. Hydraulic and Electrical overload protection

6. Squaring Arm and Front Support Arms

7. MD11 NC control(Estun E21S NC control can be optional)

8. Germany Bosch-Rexroth Hydraulic

9. Telemecanique/SchneiderElectrics

10. Hydraulic and Electrical overload protection

11. Delta inverter with ball screw and polished rod with 0,05 mm accuracy.

12. Side guard is standard meeting CE regulations.

Hydraulic system

Adopt integrated hydraulic control system, more reliable and easy for maintenance.Hydraulic system is from Bosch -Rexroth,Germany.All pipes, flange and joint with vibrations proof and leakage proof design and setting All seals in cylinder is Volqua from Japan,the most famous brand,good quality and high performance

Overload overflow protection is outfitted to hydraulic system,which can assure no leakage,and the oil level can be read or seen directly.The hydraulic system is made in compliance with current regulations.

Electrical system

Electrical Cabinet under the standard of IP65, Electrical under international CE Standard, safe and reliable, strong anti interference capability.Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.Front Side Covers with safety switches, Back light safety guards,Foot pedal conforming to CE regulation.

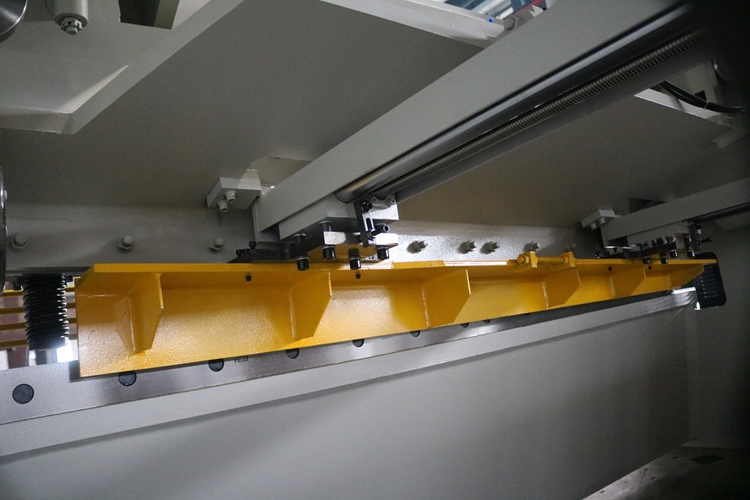

Blade Adjust and Cutting Precision:

Shearing angle is Variable, which can reduce the shearing deformation of sheet metal and can shear much thicker sheet metal. Function of shearing in sections, function of aligning with light.Upper blade holder has inward tiling structure to facilitate material feed in and also enhance accuracy of the work piece.

Rectangular blades with four cutting edges to prolong working life, adjustable shearing angle to reduce deformation of the sheet.

Screw ball for guillotine metal shearing machine with E21S controller

Hydraulic for guillotine metal shearing machine with E21S controller

E21S controller for guillotine metal shearing machine with E21S controller

front support for guillotine metal shearing machine with E21S controller

Anhui Runbang Heavy Industry Machinery Co., Ltd.

MTCNC concentrates on the research, development, manufacture, sale and service in metal fabrication equipment.

We supply metal sheet shearing, bending, punching, rolling machine tool. and complete metal fabrication solution.

Manufacturing Part

gantry milling machine

gantry drilling machine

gantry boring machine

Material Stock Part

Warehouse Part

Abundant Stock

1. Technical solutions

: we can provide technical solutions within one day.

2. Online video:

show you machine working video in factory . ( update every month)

3. Installation service:

this is available with all of our machines,

4. Training service

: Our technician will teach you how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5. Quality guarantee

: 1 year warranty, we provide lifetime service. We arrange final test before shipment, After making sure machine is the best performance, then make shipments.

6. 100% response rate:

we will reply your question within 12 hours.

Lead time

4 to 8 mm plate shear 15 days

10 to 50 mm plate shear 20 to 40 days

Payment Method

30% T/T in advance, the balance paid before shipping

irrevocable L/C at sight

|

Packaging

|

|

|

|

Size

|

3200x1750x1800

|

|

|

Weight

|

4.8Ton

|

|

|

Packaging Details

|

Plastic film packge

plywood box package

|

|

|

Delivery Details

|

FCA to your consignee

FOB PORT to Shanghai

CIF PORT in your country

|

|

1.Q:Are you a manufacturer or a trading company?

A:We are a manufacturer; We specialize in metal sheet metal steel processing equipment.

2.Q:How to choose a bending machine?

A:Please tell us the following information in detail:

- Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model;

3.Q:Where is your factory? How can I get there?

A:You can fly to NanJing LuKou airport directly, we will pick you up in the airport. All our customers, both inland and abroad, warmly welcome to visit us!

4.Q:How do you ensure quality in the factory?

A:Quality culture.:We always attach great importance to quality control from the beginning to the end. Our factory has obtained ISO, CE certification.

5. Q:How can I pay?

A:You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

6. Q:How long to produce ?

A:Delivery time:20 days.

7. Q:Minimum order quantity?

A:1 set