- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINGBO

-

Voltage:

-

as client's requirement

-

Dimension(L*W*H):

-

8.2*1.5*1.6m

-

Weight:

-

6.2 kg

-

Warranty:

-

365 days

-

use:

-

roof and wall

-

cutting:

-

hydraulic cutting

-

MOQ:

-

1 set

-

thickness:

-

0.3--0.8mm

-

control system:

-

PLC

-

port:

-

tianjin

-

certification:

-

ISO 9001:2008

-

delivery time:

-

31 days

-

spare parts:

-

easy damaged parts

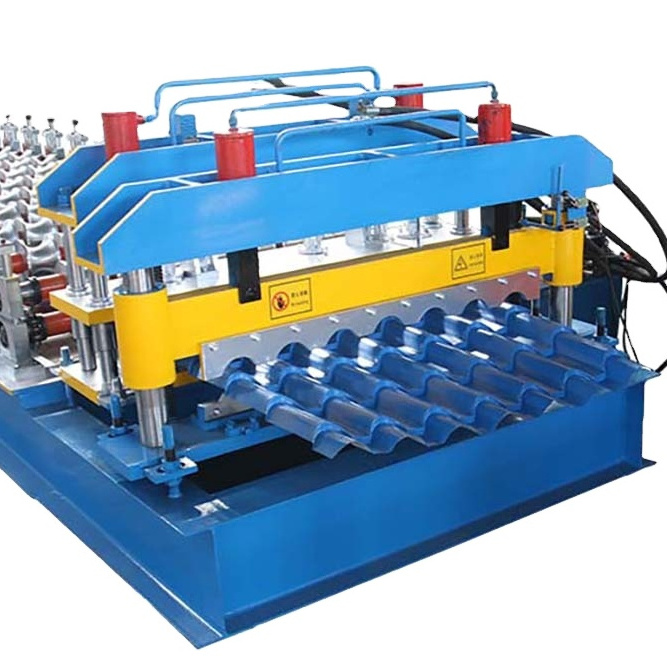

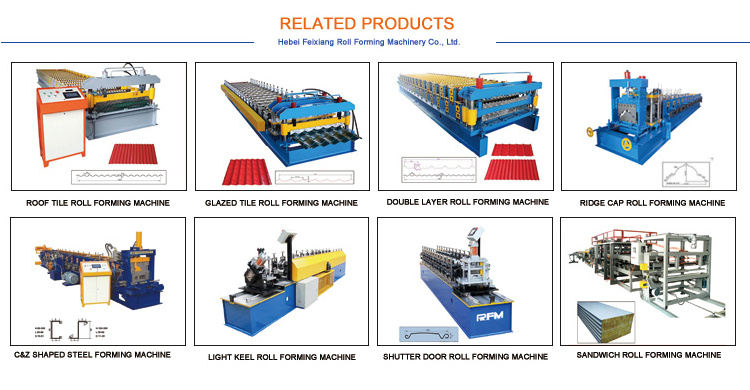

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

5-10m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINGBO

-

Voltage:

-

as client's requirement

-

Dimension(L*W*H):

-

8.2*1.5*1.6m

-

Weight:

-

6.2 kg

-

Warranty:

-

365 days

-

use:

-

roof and wall

-

cutting:

-

hydraulic cutting

-

MOQ:

-

1 set

-

thickness:

-

0.3--0.8mm

-

control system:

-

PLC

-

port:

-

tianjin

-

certification:

-

ISO 9001:2008

-

delivery time:

-

31 days

-

spare parts:

-

easy damaged parts

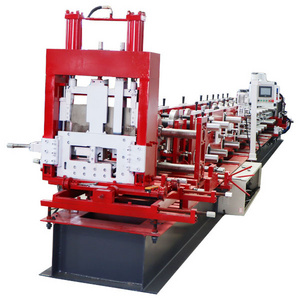

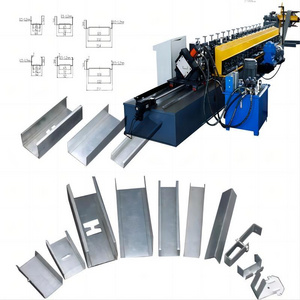

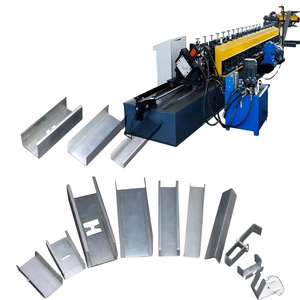

Pass CE and ISO Automatic Roll Forming Machine

1.The chart of process flow:

Decoiling--active feeding---forming---measuring lengh---cutting---product to stand

2.Main equipment:

Decoiler,main forming machine,hydraulic cutting,electric system(plc),hydraulic system,product stand.

3.Technical parameters

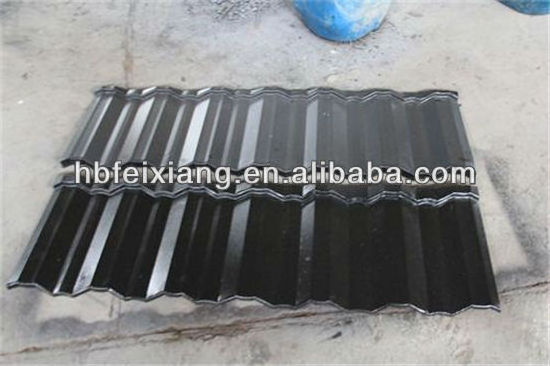

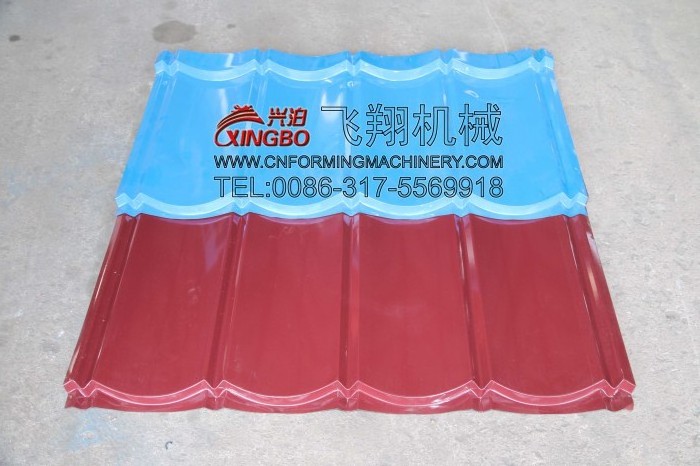

1)Profile

A.thickness:0.3--0.8mm

B.Feeding width:1000mm

2)inner tight decoiler

A.coil inner diameter:450mm--550mm

B.max width of coiling:1250mm

C.max weight of loading:5000kg

3)main forming machine

(1) Suitable material: color steel

(2) Thickness of the plate : 0.3-0.8mm

(3) Input width of the plate: 1 2 5 0 /1000 mm

(4)Width of the plate after forming: 1000/800 mm

( 5 ) Productivity : 2-10 m/min

( 6 ) Roller steps :1 6 rows

( 7 ) Roller material: 45# steel Rolling chromium thickness:0.05 mm

( 8 ) Diameter of active shaft : 80 mm

(9) Wall thickness of the main forming machine: 16mm steel plate

(10)Main forming machine body : 300mmH steel

(11) Transmission chain is 1 ’’

Reducer is 5.5kw which works stably and no noise

(12) Cutting hydraulic systerm adpats CDF-10 gear pump, the motor power is 4kw , no noise, work stably, long life expentancy.

(13) PLC control systerm, easy to operate, high precision and work stably.

( 14 ) Dimensions of major structure: 85 00mm*16 0 0mm*1 20 0mm

4)cutting system

A.hydraulic cutter

B.Blade and mould material:Cr12 steel with quenched treated 60-62

Cutting system advanced hydraulic drive,after automatic cutting after forming.no

5)control system

A.PLC: taida form Taiwan

B.Coder:from south korea

6)hydraulic system

A.advanced hydraulic system from taiwan

B.Power:3kw

4.Spare Parts

1).Easy damaged parts: conk 2 pcs, fuse-link 4 pcs

2).Rubber mat 1 pcs;

3).Bolt spanner 1 pcs

Terms:

1.Delivery:in stock

2.Package:export standard package for container

3.Payment:TT (30% by TT in advance,70% by TT after you inspect machine we need)

4.Delivery date:within 30 working days after receiving deposit

5.Products Warranty:12 month,and we will provide the technical support for whole life of the equipment.