- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5010*3010*4100mm

-

Year:

-

2023

-

Weight (KG):

-

16500 kg

-

Power (kW):

-

90

-

Blades material:

-

SKD11

-

Composed of:

-

motor, reducer,alloy blade,machine frame,box,work platform

-

Blade quantity:

-

40pcs

-

Blade diameter:

-

500mm

-

Broken size:

-

50-80mm

-

Spindle speed:

-

18-35 r/min

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Model Number:

-

YX1200

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5010*3010*4100mm

-

Year:

-

2023

-

Weight (KG):

-

16500 kg

-

Power (kW):

-

90

-

Blades material:

-

SKD11

-

Composed of:

-

motor, reducer,alloy blade,machine frame,box,work platform

-

Blade quantity:

-

40pcs

-

Blade diameter:

-

500mm

-

Broken size:

-

50-80mm

-

Spindle speed:

-

18-35 r/min

Product Description

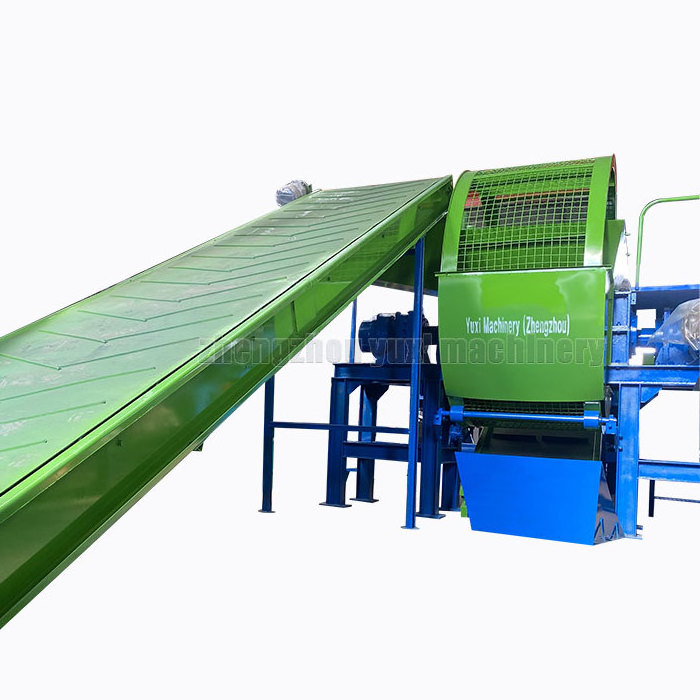

Yuxi double shaft shredder is specially designed for tire chips size separation. The shredded chips from prime shredder will drop on the rotary screen, and small chips will fall on the conveying belt, the big chips will be feed in the shredder for shredding and recycling again. The final chips will be around 50~60mm.

Products Parameter

|

Shredder with trommel

|

YX1300

|

YX1200

|

YX1000

|

YX800

|

|

Power

|

45kw*2/37kw*2

|

45Kw*2/22Kw*2

|

37kw*2/22kw*2

|

22kw*2/15kw*2

|

|

Voltage

|

as per request

|

as per request

|

as per request

|

as per request

|

|

Cutting Chamber L*W

|

1304*920mm

|

1204*920mm

|

1004*680mm

|

804*680mm

|

|

Blade Diameter

|

450mm

|

450mm

|

450mm

|

450mm

|

|

Equipment Dimensions

L*W*H(mm) |

5120*3010*4100

|

5010*3010*4100

|

3800*3010*3100

|

3350*3010*3050

|

|

Equipment Weight

|

18500kg

|

16500Kg

|

7000kg

|

5700kg

|

|

Hopper Opening

L*W*H(mm) |

2050*1650*1000

|

1850*1650*900

|

1300*1400*700

|

1150*1300*800

|

|

Final Product

|

50mm

|

50mm

|

50mm

|

50mm

|

Application

Raw material

: Truck and buses tires, car tires and passenger tires in general.

Final Product

:Waste tires of less than 1200 mm and rubber materials can be crushed into 50mm block.

Product Features

①. Overloading automatic reversal function.

②.Replaceable blade bit tool is fixed by both screws and grooves on the blade base, so the screws won’t get loosen.

③. The transmission parts are connected by coupling to reduce vibration and protect the main shaft and reducer from force loss.

④. Crushing chamber is open structure, easily for maintenance.

⑤.High torque and strong power, ensures low noise and power consumption with high productivity.

⑥. Blades are made one of best material 9Cr2Mo, long service life.

⑦.Planetary reducer is equipped with high accuracy, high loading power, high speed ratio, durable use, low noise, low vibration and low inertia.

Product Processing

With the professional and meticulous production of each step, it can ensure your final shredder robust and reliable. This is also our standard operating procedure. High quality equipment and production and low maintenance costs are merely a few of the advantages which makes our customers choose us over and over again.

Customer Working Site

Yuxi machinery is exported to more than 60 countries and regions around the world, helping customers design and produce waste tire recycling solutions. Can provide customers with the nearest customer site for your reference.

Our Factory

COMPANY PROFILE

1.YuXi Machinery Equipment (Zhengzhou) Co., Ltd was established in 1998. And we obtained 32 patents and 3 invention patents.Our company is specialized in designing, researching, producing the waste recycling equipment and provide waste treatment solutions. We have professional technical team to provide high quality and efficient after-sale service.

2.Our products are successfully exported to United States, Europe, Australia, Southeast Asia, Middle East, South America , Egypt and other countries.

3.High quality, high efficiency, energy saving and environmental protection is the belief that our company has been firmly established.

.

Our Sevice

1.Engineers will be sent to help you installing the machine, debugging the machine, training your worker, until your machines working normally and your workforce operate skillfully.

2.Two year warranty for the spare parts and 20 years warranty for the heavy duty machine(without spare part) in normal working process.

3.Spare parts delivered at cost in short time to ensure your daily production.

4.Life-long maintaining and technical support.

Certifications

Hot Searches