- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

pipeline, thermometer

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Dimension(L*W*H):

-

2.1*2.1*2.4M

-

Voltage:

-

380V

-

Applicable Industries:

-

forestry, Wood industry, Furniture Factory

-

Weight (KG):

-

1200

-

Product name:

-

Lifting type carbonization furnace

-

Production Capacity:

-

1-1.5T

-

Applicable raw materials:

-

Bamboo, coconut shell, log, rice husk,wood chips, etc.

-

aw material size:

-

Within 30cm

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Materials:

-

Carbon Steel

-

Color:

-

Customer's Request

-

Heat source material:

-

Coal, wood, natural gas, diesel, etc.

-

Carbonization method:

-

Dry distillation carbonization

-

Carbonization time:

-

Decide time based on raw materials

Quick Details

-

Place of Origin:

-

Henan,China

-

Marketing Type:

-

New Product 2022

-

Warranty of core components:

-

1 years

-

Core Components:

-

pipeline, thermometer

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Dimension(L*W*H):

-

2.1*2.1*2.4M

-

Voltage:

-

380V

-

Applicable Industries:

-

forestry, Wood industry, Furniture Factory

-

Weight (KG):

-

1200

-

Product name:

-

Lifting type carbonization furnace

-

Production Capacity:

-

1-1.5T

-

Applicable raw materials:

-

Bamboo, coconut shell, log, rice husk,wood chips, etc.

-

aw material size:

-

Within 30cm

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Materials:

-

Carbon Steel

-

Color:

-

Customer's Request

-

Heat source material:

-

Coal, wood, natural gas, diesel, etc.

-

Carbonization method:

-

Dry distillation carbonization

-

Carbonization time:

-

Decide time based on raw materials

|

Compact charcoal making machine manufacturer/carbonization furnace to carbonize wood charcoal/carbon fiber carbonization furnace

|

|

|

|

|

||||

Product Description

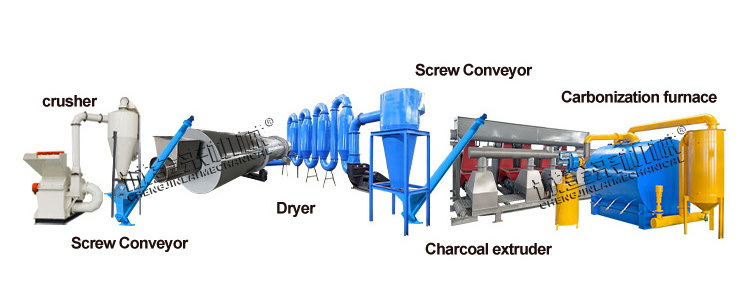

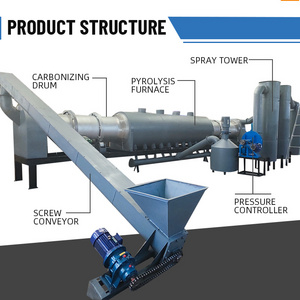

Horizontal charcoal furnace

is a new kind of air flow type carbonization stove, which can also be called charcoal kiln, charcoal making machine, charcoal stove. It is used to make charcoal from wood and all kinds of biomass.Easy to operate, safety, environmental protection and high production efficiency. It is the main ideal equipment of the charcoal production line.

▶

Thermometer

: Measuring furnace temperature.

▶

Sealing cap

:Seal to maintain the temperature inside the furnace, to ensure into a good effect of carbonization.

▶

Combustion Chamber

:

Fire the furnace and to make the charcoal. There is the combustible gas to produce and this gas can be sent to the bottom of the fire mouth to let the machine heat.

▶

Carbonization Chamber

:

The raw materials are thermally decomposed in combustion chamber to generate a large amount of acetic acid, methanol, wood tar and other liquid products; also produced combustible gases such as methane and ethylene.

▶

Smoke recovery system

:The flammable gases are treated by flue gas purification, and are returned to the carbonization machine for burning, providing heat to the carbonization furnace, increasing the furnace temperature, and generating carbon at high temperatures.

|

Specification

|

|

|

|

|

||||

|

Model

|

Inner cylinder size

(Diam x Length)

|

Dimension(length*width*height)

|

Weight

|

Output

|

||||

|

CJL-50

|

0.5*0.75m

|

1.1*0.7*1m

|

130kg

|

50-100kg

|

||||

|

CJL-250

|

1*1.5m

|

1.8*1.2*1.6m

|

450kg

|

200-300kg

|

||||

|

CJL-500

|

1.5*1.5m

|

1.8*1.7*2.2m

|

1000kg

|

500-600kg

|

||||

|

CJL-1000

|

1.5*3m

|

3.8*1.8*2.4m

|

2800kg

|

1500kg

|

||||

|

Machine size can be customized according to the your required output.

|

|

|

|

|

||||

How to use?

Machine details

Fireproof cotton

Fume recovery system

All kinds of wood, log, branch, bamboo, coconut shell, jute sticks, biomass briquette etc can be used for this machine to make the charcoal.

Production Line

Crushing --- Drying --- Press briquette --- Carbonizing briquette to charcoal

Hot Searches