- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DEMETER

-

Power:

-

130KW

-

Dimension(L*W*H):

-

25000*2000*2000mm

-

Weight:

-

15000 kg

-

Prooduct name:

-

Paper tray machine

-

Coil material layers:

-

2 layers

-

Coil material width:

-

500-1600mm

-

Max coil material diameter:

-

1500mm

-

Max coil material weight:

-

1T

-

Max pressure of the mold:

-

15T

-

Max width of forming:

-

1000mm

-

Max die travel:

-

1000mm

-

Method of heating:

-

Electromagnetic heating

-

Air source (external) pressure:

-

0.8mpa

Quick Details

-

Production Capacity:

-

Other

-

Product Type:

-

Fruit /Egg Tray Machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DEMETER

-

Power:

-

130KW

-

Dimension(L*W*H):

-

25000*2000*2000mm

-

Weight:

-

15000 kg

-

Prooduct name:

-

Paper tray machine

-

Coil material layers:

-

2 layers

-

Coil material width:

-

500-1600mm

-

Max coil material diameter:

-

1500mm

-

Max coil material weight:

-

1T

-

Max pressure of the mold:

-

15T

-

Max width of forming:

-

1000mm

-

Max die travel:

-

1000mm

-

Method of heating:

-

Electromagnetic heating

-

Air source (external) pressure:

-

0.8mpa

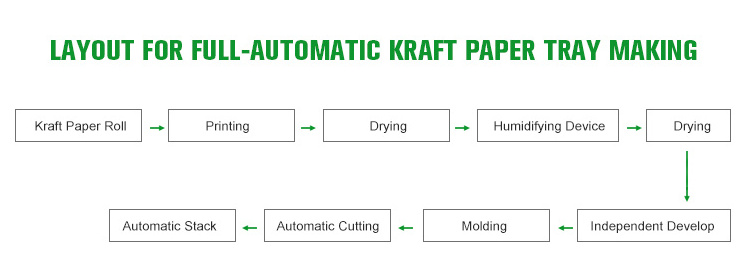

Products Description

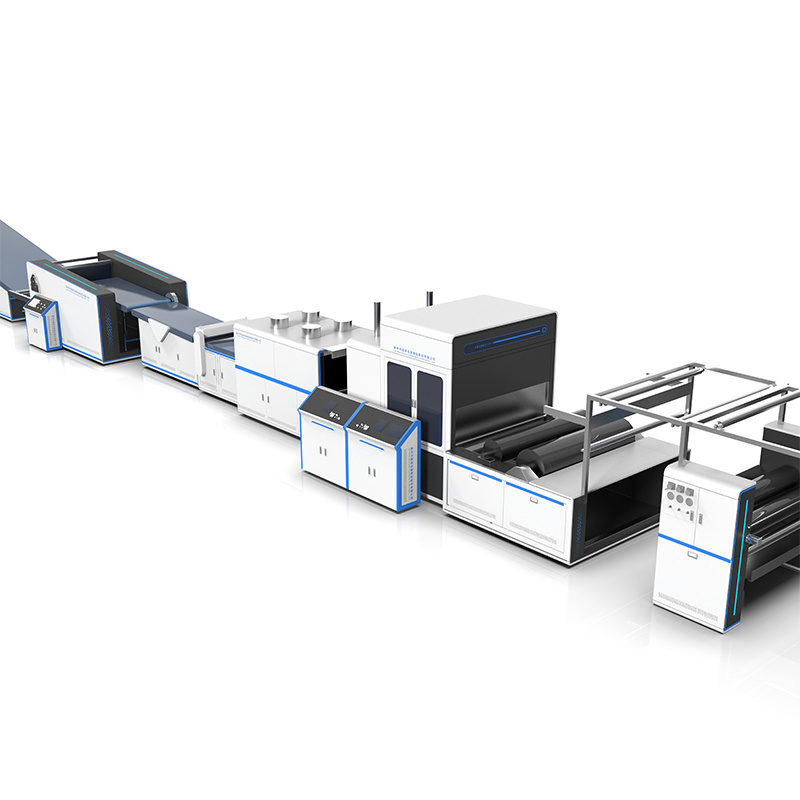

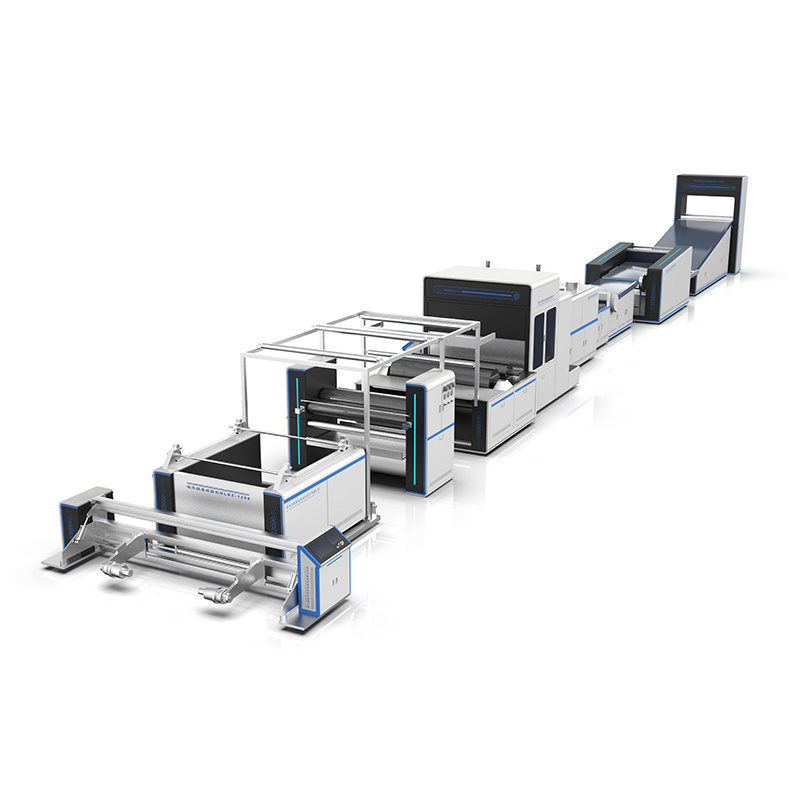

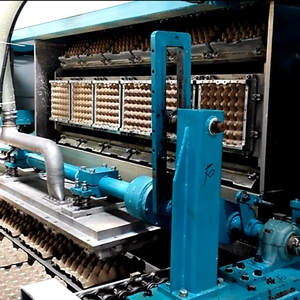

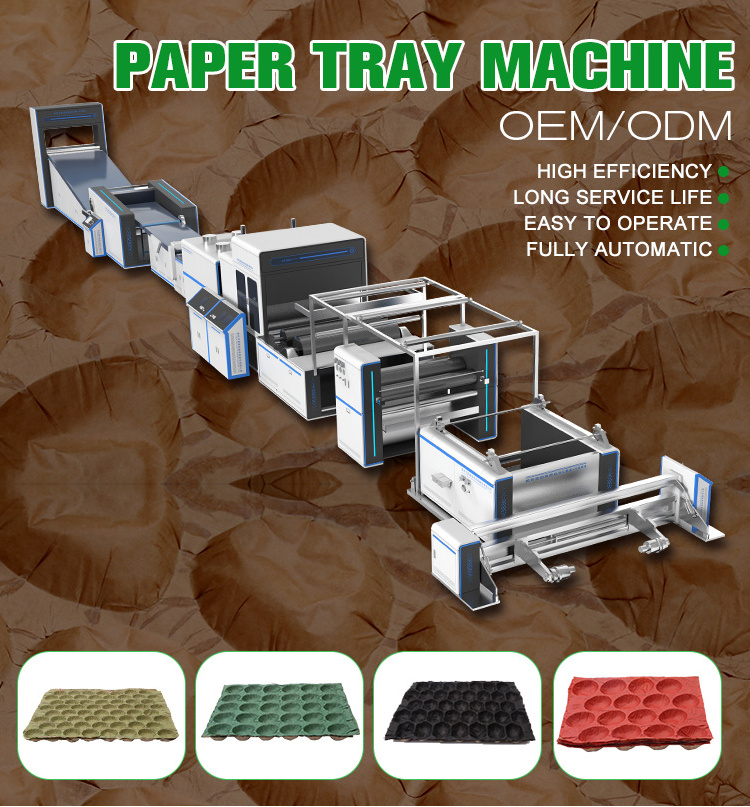

Paper tray production equipment is one of the important equipment in the field of paper packaging. Its working principle is similar to assembly line production in industrial manufacturing. Starting from waste paper or wood pulp, it goes through multiple processes such as shaping, drying, pressing and forming, and finally forms a paper tray with a certain strength and stability. These equipment can be flexibly configured according to production needs to meet production of different scales and requirements. The application of paper tray production equipment not only contributes to the effective use of resources, but also promotes the sustainable development of the packaging industry.

|

Item

|

Unit

|

Type B(GLBZ--1000)

|

|

Max Speed

|

m/minute

|

30

|

|

Coil material layers

|

layers

|

2

|

|

Pieces formed by mold singly

|

Pieces

|

4--6

|

|

Coil material width

|

mm

|

500--1600

|

|

Max coil material diameter

|

mm

|

1500

|

|

Max coil material weight

|

T

|

1

|

|

Max pressure of the mold

|

T

|

15

|

|

Max width of forming

|

mm

|

1000

|

|

Max weight of the mold ( up mold)

|

KGS

|

800

|

|

Max weight of the mold ( bottom mold)

|

KGS

|

800

|

|

Max die travel

|

mm

|

1000

|

|

Max paper cutting area

|

mm

|

1000

|

|

Method of heating

|

/

|

Electromagnetic heating

|

|

Air source (external) pressure

|

mpa

|

0.8

|

|

Power supply

|

/

|

Three-phase four-wire system 380v 50HZ

|

|

Max power

|

KW

|

130

|

|

Paper interval control mode

|

/

|

AI Fully automatic control

|

|

Max out size of the machine (L*W*H)

|

mm

|

25000*2000*2000

|

|

weight of the machine

|

T

|

Around 15

|

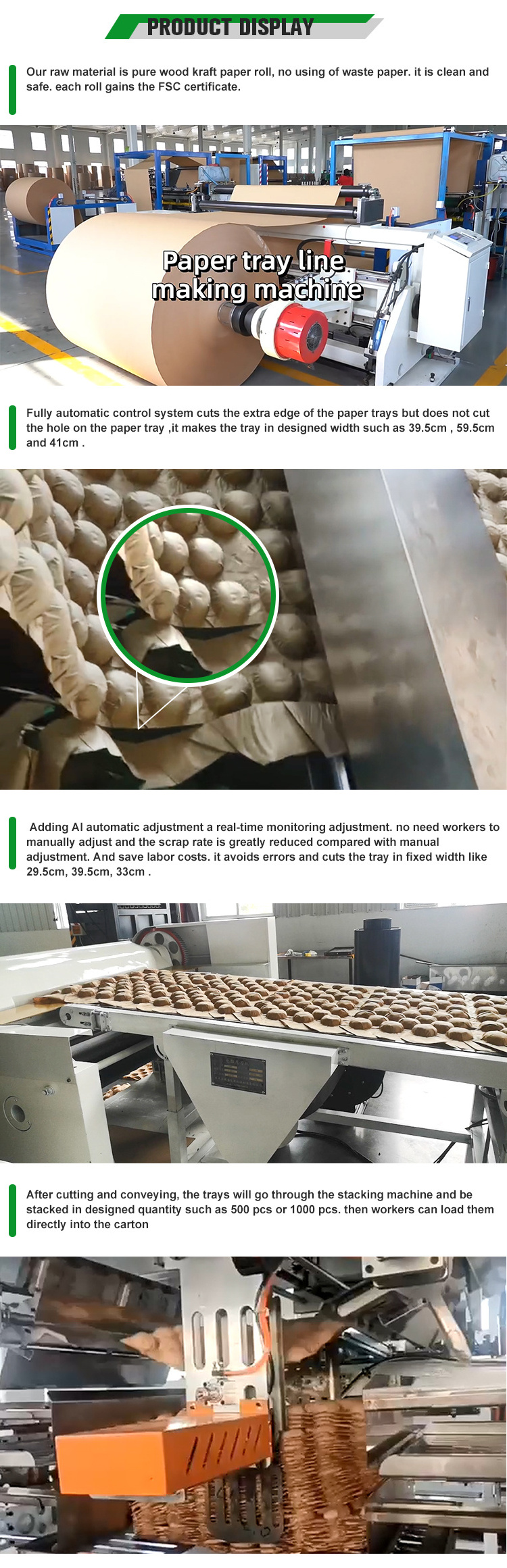

Product Display

Final Products

Application

Packaging & Shipping

Hot Searches