- Product Details

- {{item.text}}

Quick Details

-

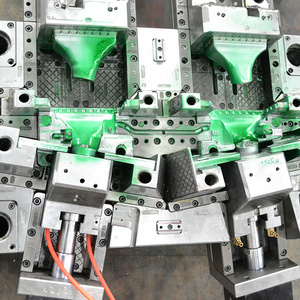

Mould material:

-

42CrMo

-

Product Name:

-

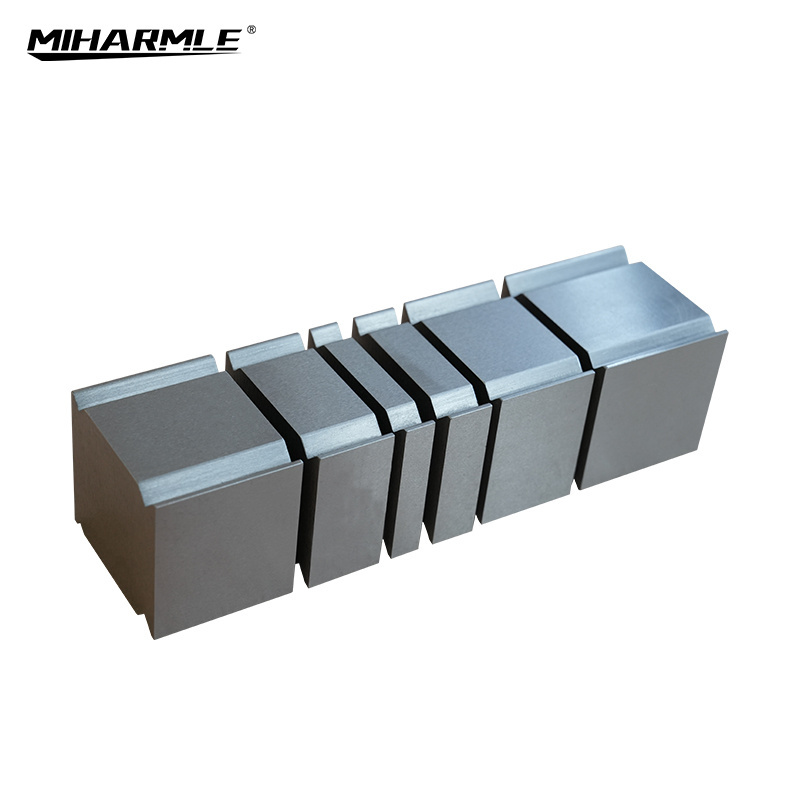

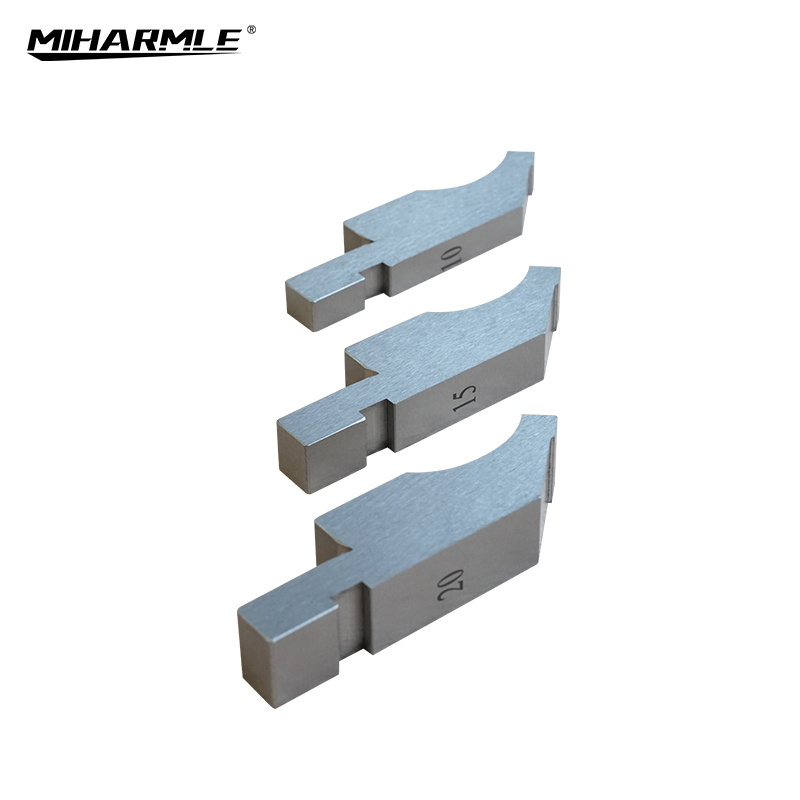

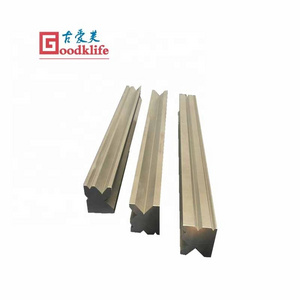

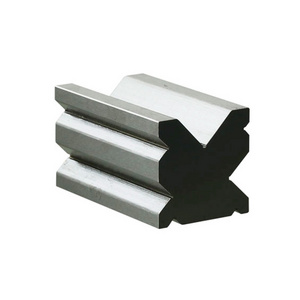

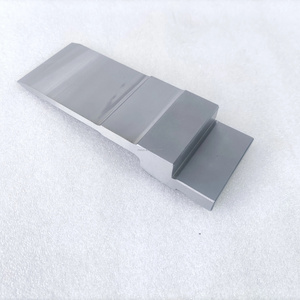

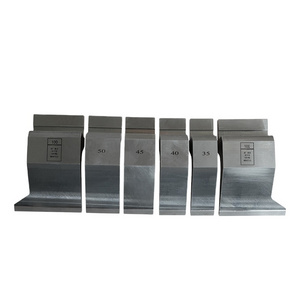

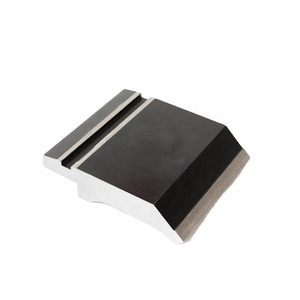

Press Brake Dies

-

Keyword:

-

press brake mould

-

Surface treatment:

-

Heat Treatment

-

Design software:

-

CAD

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

OEM:

-

yes

-

ODM:

-

yes

-

Surface Tolerance:

-

0.02mm

-

Hardness:

-

47-53

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Miharmle

-

Mould material:

-

42CrMo

-

Product Name:

-

Press Brake Dies

-

Keyword:

-

press brake mould

-

Surface treatment:

-

Heat Treatment

-

Design software:

-

CAD

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

OEM:

-

yes

-

ODM:

-

yes

-

Surface Tolerance:

-

0.02mm

-

Hardness:

-

47-53

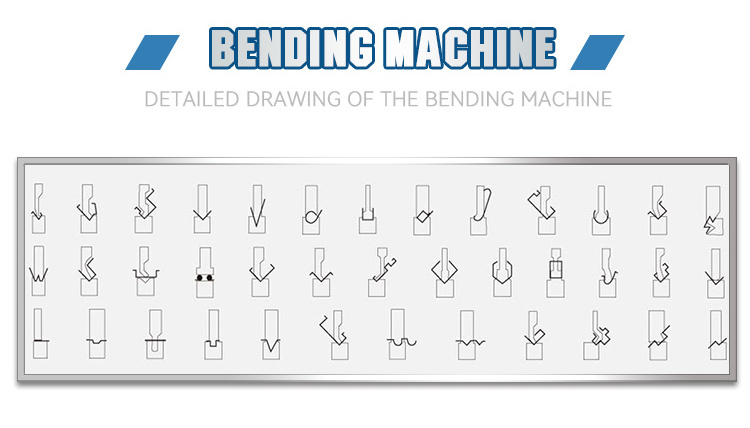

PRESS BRAKE TOOLING Q&A

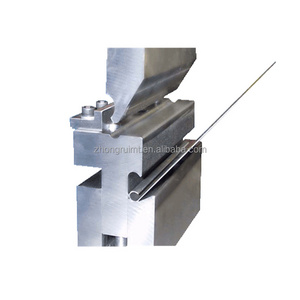

Q1.Do you know what the sheet metal material, thickness, workpiece length, machine model or clamping method determine?

A: different materials have different rebound coefficients. Especially for arc molds, the thicker the sheet, the smaller the

rebound coefficient. The thickness of the sheet determines the width of the bottom die notch.The work piece length determines the die length.And different model machine, different clamping method. This determines the shape of the upper die handle. Our engineers will design the initial drawing of the tooling based on these data, generally we will check the drawings with the customer within 12 hours. Besides common toolings, we can also customize Amada and Trumpf toolings.

Q2.Do you know what are the advantages of the two materials 42CRMO and 55CRSI?

A: 42CRMO material has good toughness and wear resistance;

The quenching hardness of 55CRSI material is higher. We will make according to the requirements of customers. If you don't know which material to use, our engineers will help you.

Q3. Do you know the step of raw material forging in the process? What are its benefits?

A: ①The impurities in the material are discharged, and the carbon structure is tighter.

②Forged to the required size for easy processing.

Q4. Do you know vacuum insulation?

A: After the heat treatment and rough grinding of the mold, we will have a step of vacuum insulation, the purpose is to protect the life of the mold, so that the mold is not easy to crack and more wear-resistant. Some factories do not have this step in the production process, which greatly reduces the life of the mold. So next time, when you purchase molds, be sure to ask the factory if they do this step!

Q5. Do you know why the acceptance process runs through the entire mold manufacturing process?

A: ①First inspection: to check before each process, check whether it meets the requirements and whether the previous step is completed

②Process inspection: check in each process

③Final inspection: We will check on the marble working platform, because the marble material is more stable, there will be no changes in thermal expansion and contraction, and the straightness is good.

A: different materials have different rebound coefficients. Especially for arc molds, the thicker the sheet, the smaller the

rebound coefficient. The thickness of the sheet determines the width of the bottom die notch.The work piece length determines the die length.And different model machine, different clamping method. This determines the shape of the upper die handle. Our engineers will design the initial drawing of the tooling based on these data, generally we will check the drawings with the customer within 12 hours. Besides common toolings, we can also customize Amada and Trumpf toolings.

Q2.Do you know what are the advantages of the two materials 42CRMO and 55CRSI?

A: 42CRMO material has good toughness and wear resistance;

The quenching hardness of 55CRSI material is higher. We will make according to the requirements of customers. If you don't know which material to use, our engineers will help you.

Q3. Do you know the step of raw material forging in the process? What are its benefits?

A: ①The impurities in the material are discharged, and the carbon structure is tighter.

②Forged to the required size for easy processing.

Q4. Do you know vacuum insulation?

A: After the heat treatment and rough grinding of the mold, we will have a step of vacuum insulation, the purpose is to protect the life of the mold, so that the mold is not easy to crack and more wear-resistant. Some factories do not have this step in the production process, which greatly reduces the life of the mold. So next time, when you purchase molds, be sure to ask the factory if they do this step!

Q5. Do you know why the acceptance process runs through the entire mold manufacturing process?

A: ①First inspection: to check before each process, check whether it meets the requirements and whether the previous step is completed

②Process inspection: check in each process

③Final inspection: We will check on the marble working platform, because the marble material is more stable, there will be no changes in thermal expansion and contraction, and the straightness is good.

Anhui Harmle Machinery Technology Co.,Ltd. is a comprehensive manufacturer of sheet metal processing equipment in China. The first factory mainly produces press brake machines,shearing machines, laser cutting machines,punching machines, ironworkers,grooving machines and other stamping machine tools, while the second factory mainly produces ventilation ducting equipment including air duct lines,folding machines, lock forming machines, roller bending machines, flange forming machines, etc. Anhui Harmle is located in Bowang District, Anhui Province, which is known as "the first town of China's die-cutting machine tools" with superior location and convenient transportation. The factory covers a total area of 40,000 square meters and has more than 100 employees in engineering, production and sales.The company has passed ISO9001 quality management system certification as well as CE certification for several products. The annual production value of Harmle Machinery reaches RMB 55 million, and the company's products are exported to more than 50 countries and regions around the world, such as Europe, America, the Middle East, and South Central Asia. The annual export value reaches thirty-five million.

FAQ

1.Q: Who are we?

A: We are MIHARMLE, a manufacturer and exporter specialize in the sheet metal processing equipment.

2. Q:How to get the most suitable press brake tooling?

A: Please tell us what you want, the size/dimension, drawing, applied bending material, raw material, and other information.

3.Q: Can you supply the relevant documentation?

A: Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.Q: What is the average lead time?

A: The lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

5.Q: How can I pay?

A: You can pay by T/T, Western Union, Money Gram, Paypal; 30% deposit; pay off the 70% balance before shipment.

6.Q: How about your after-sale service?

A: In order to serve our customers well, the company is specially managed with ERP software.It systematically assigns

responsibilities and manages the process from pre-sales, sales and after-sales aspects such as consultation, quotation, order placement, export, remote or door-to-door commissioning and installation.

A: We are MIHARMLE, a manufacturer and exporter specialize in the sheet metal processing equipment.

2. Q:How to get the most suitable press brake tooling?

A: Please tell us what you want, the size/dimension, drawing, applied bending material, raw material, and other information.

3.Q: Can you supply the relevant documentation?

A: Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.Q: What is the average lead time?

A: The lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

5.Q: How can I pay?

A: You can pay by T/T, Western Union, Money Gram, Paypal; 30% deposit; pay off the 70% balance before shipment.

6.Q: How about your after-sale service?

A: In order to serve our customers well, the company is specially managed with ERP software.It systematically assigns

responsibilities and manages the process from pre-sales, sales and after-sales aspects such as consultation, quotation, order placement, export, remote or door-to-door commissioning and installation.

Hot Searches