- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

0.6 MPa

-

Heating Power (kW):

-

4.5 kW

-

Air Comsumption(L/min):

-

1 L/min

-

Water Comsumption(L/min):

-

1 L/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

sme

-

Voltage:

-

380V/50Hz/3phase

-

Dimension(L*W*H):

-

1900*790*1700mm

-

Weight (T):

-

950 T

-

Warranty:

-

1 Year

-

Suitable material:

-

PS/PVC/PET/PP

-

Application:

-

Cup lid/cover

-

Max. forming size:

-

330*160mm

-

Max. forming height:

-

47mm

-

Stroke:

-

65-165mm

-

Tool cooling:

-

Tap water recycle water 60L/H

-

Type:

-

Full Automatic Vacuum Forming Machine

-

Name:

-

Plastic Lid Making Machine

-

Punch recycle time:

-

15-40(Times/Min)

Quick Details

-

Max.Forming Height(mm):

-

47 mm

-

Forming Width (mm):

-

160 mm

-

Forming Length (mm):

-

330 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Heating Power (kW):

-

4.5 kW

-

Air Comsumption(L/min):

-

1 L/min

-

Water Comsumption(L/min):

-

1 L/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

sme

-

Voltage:

-

380V/50Hz/3phase

-

Dimension(L*W*H):

-

1900*790*1700mm

-

Weight (T):

-

950 T

-

Warranty:

-

1 Year

-

Suitable material:

-

PS/PVC/PET/PP

-

Application:

-

Cup lid/cover

-

Max. forming size:

-

330*160mm

-

Max. forming height:

-

47mm

-

Stroke:

-

65-165mm

-

Tool cooling:

-

Tap water recycle water 60L/H

-

Type:

-

Full Automatic Vacuum Forming Machine

-

Name:

-

Plastic Lid Making Machine

-

Punch recycle time:

-

15-40(Times/Min)

Plastic cup covers,lids thermoforming machine

Features

1) Sensor controls are adopted by pneumatic system.

2) Automatic, equipped with PLC touch screen.

3) AVF-L series support frequency conversion, and can adjust the length of stroke easily. It is simple and convenient to change the mold.

Product Introduction

AVF-L series automatic blow molding and plastic sucking lids forming machine are developed by our research and development personnel according to the demand of packing market. In combination with the advantages of aluminum-plastic blister packing machine and plastic sucking forming machine, AVF-L series is a new type production developed in light of pharmaceutical standard GMP and food standard QS. This machine adopts a fully automatic flow covering blow molding or plastic suction molding, punching and diet cutting as the special properties of products required by the users. It is applicable to the plastic ware such as PVC, PET, PS medicine trays, and cup lids thermoforming boxes. And have a good selling in this market.

Technical Data AVF-L series

| Model | AVF-350L | AVF-450L |

| Max. forming size | 330×160mm | 430×210mm |

| Max. forming height | 47mm | 47mm |

| Stroke | 65-165mm | 60-240mm |

| Power supply | 380V/50Hz/3phase | 380V/50Hz/3phase |

| Air supply | 0.5-0.8Mpa | 0.5-0.8Mpa |

| Power Consumption | 4.5KW | 8.5KW |

| Tool cooling | Tap water recycle water 60L/H | Tap water recycle water 60L/H |

| Punch recycle time | 15-40(Times/Min) | 15-40(Times/Min) |

| Machine size(L×W×H) | 1900×790×1700mm | 3500×1000×1800mm |

| Net weight | 950Kg | 1700Kg |

Schematic diagram

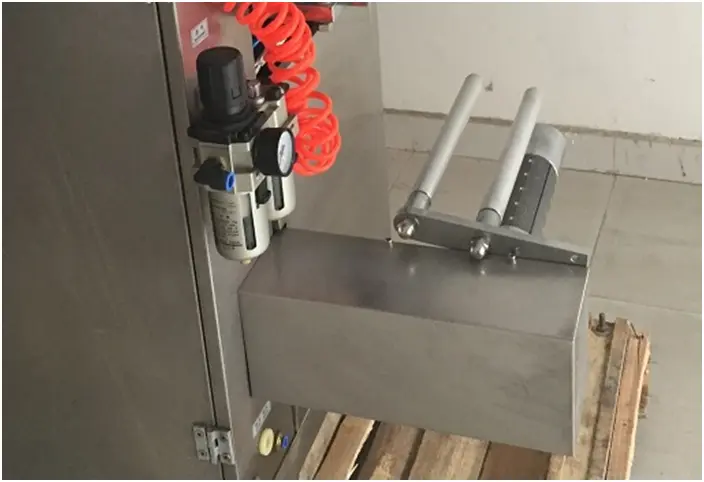

Material upload part

Heating and forming part

Pneumatic clamp device

Punching and conveyer part

Samples

Remarks: The price is non-including the mold cost.

Payment Terms: T/T 40% deposit before production, 60% balance before delivery date;

Delivery time: 35-40 business days after deposit;

Validity: 30 days after quote.

Departure Port: Guangzhou Huangpu or Shenzhen port;

Warranty: We guarantee these machines for one year. And we supply some spare parts with the machine, operation manual and operation CD, etc.

Service: We will send engineer who install and train in your company for approximately 7 to 10 days, after machine is arrived your place. And the flight tickets, visa and accommodation of engineer will be arranged by buyer, also the buyer need pay 100USD/day for training cost.