Loading capacity: 5T

Inner diameter: 470-530mm

Steel coil width :.According to your actual drawing.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.5-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TOPPO

-

Voltage:

-

380V 50Hz 3 Phase

-

Dimension(L*W*H):

-

about 7.2*0.6*1.3 m

-

Weight:

-

1650 kg

-

Feeding width:

-

Customized

-

Marketing Type:

-

Easy to operate

-

Operation Language:

-

English/Spanish/Chinese

-

Operate Style:

-

Auto/Manual

-

Raw material:

-

Galvanized Strip

-

Motor Brand:

-

Japanese Simens

-

PLC Brand:

-

Delta/MITSUBISHI/SIEMENS

-

Cutting Blade:

-

Cr12Mov with quenched treatment

-

Profile:

-

as customer's requirement

-

Color of Machine:

-

blue, gray, or your required color

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

0-45 m/min

-

Rolling thinckness:

-

0.5-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TOPPO

-

Voltage:

-

380V 50Hz 3 Phase

-

Dimension(L*W*H):

-

about 7.2*0.6*1.3 m

-

Weight:

-

1650 kg

-

Feeding width:

-

Customized

-

Marketing Type:

-

Easy to operate

-

Operation Language:

-

English/Spanish/Chinese

-

Operate Style:

-

Auto/Manual

-

Raw material:

-

Galvanized Strip

-

Motor Brand:

-

Japanese Simens

-

PLC Brand:

-

Delta/MITSUBISHI/SIEMENS

-

Cutting Blade:

-

Cr12Mov with quenched treatment

-

Profile:

-

as customer's requirement

-

Color of Machine:

-

blue, gray, or your required color

1. Catalog

2. Details

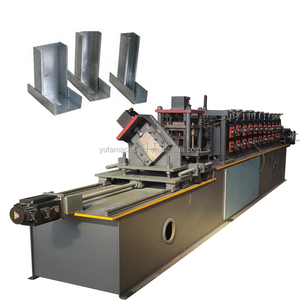

Fast Speed Metal Batten C Track U Stud Omega Profile Roll Forming Machine

The whole production process is

automatically controlled

by the computer. In this way, you can ensure accuracy and easy work.

Before production, you input your requirement into the control cabinet-for example, 3250 mm per piece, 20 pieces in total.

When the sheet comes to 3250 mm length, the machine will slow down-stop-cut-run again. When you get 20 pieces, the machine will entirely stop.

Uncoiler

Feeding table

It is used to control the width and position of the steel sheet.

The sheet is guided into the machine with correct position ,to make sure the panel is neat and parallel

The sheet is guided into the machine with correct position ,to make sure the panel is neat and parallel

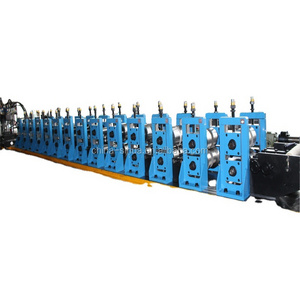

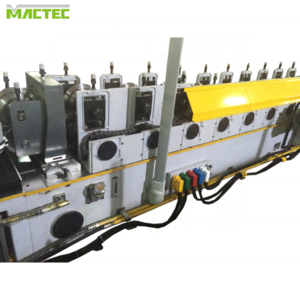

Main frame

Material :350 H steel

Feature:more table, no shaking

Feature:more table, no shaking

Forming rollers

Material:High grade 45# steel.

Roller stations :11-24 stations, according to your actual drawing.

Roller stations :11-24 stations, according to your actual drawing.

alignment device

Used to align the panel from bending up and down, left and right.

Auto cutting

Non-stop, servo tracking cutting.

the sliding rail of the cutting device adopts servo driving. it is fast, adjustable, and reliable.

the sliding rail of the cutting device adopts servo driving. it is fast, adjustable, and reliable.

Control cabinet

Suitable power:

380V, 50Hz, 3 phase. Or according to your need.

Feature:

Feature:

Adopt advanced automatic control software, achieving information management for production.

3. Related machines

4. How does TOPPO machinery make installation during covid-19?

Hereby TOPPO will explain how we do the installation of our roll forming machine.

1st, we adjust the machine in our factory. We will ask which size you are going to produce, then we set the correct parameters

accordingly before the shipment, You just start production when you get the machine, no need to change anything.

2nd, when we disassemble the machine for loading, we take videos so that you know how to connect them. It will show how to connect

the cables and tubes, put the oils, put together the physical structures, etc.

3rd, when you receive the equipment, we will build a WhatsApp or WeChat group, Our technical engineer, electrical engineer, and

sales, all will be in the group to support you in any doubt.

4th, we send you a manual in English and Spanish, so that you understand all the meanings of the buttons and how to start the

machine.

We have had many successes installing machines in the years since COVID-19. For example

1) CZ automatic exchangeable roll forming machine installed successfully in UAE, Senegal, Cango

2) Roofing sheet roll forming machine installed successfully in Qatar, Bangladesh, Philippines, Turkey, UAE, etc.

3) Slitting line installed successfully in Paraguay

4) Cut to length line installed successfully in Turkey.

TOPPO offers the best quality and the best service for our clients, especially in this situation. You don’t have to wait until the

COVID pass. You can produce the profiles right now with our machines.

5. About Us

Hot Searches