- Product Details

- {{item.text}}

Quick Details

-

heating element:

-

1800 degree heating element

-

tube material:

-

high purity alumina

-

thermocouple:

-

B type

-

usage:

-

CVD research

-

certificate:

-

CE

-

Key word:

-

CVD tube furnace

-

Display:

-

Touch Screen Digital Display

-

Delivery time:

-

30

Quick Details

-

Place of Origin:

-

Henan, China

-

Max. temperature:

-

1700c

-

working temperature:

-

1600c

-

heating element:

-

1800 degree heating element

-

tube material:

-

high purity alumina

-

thermocouple:

-

B type

-

usage:

-

CVD research

-

certificate:

-

CE

-

Key word:

-

CVD tube furnace

-

Display:

-

Touch Screen Digital Display

-

Delivery time:

-

30

1700C Tube Furnace with High Vacuum System MFC Gas Mixer / CVD tube furnace

basic introduction

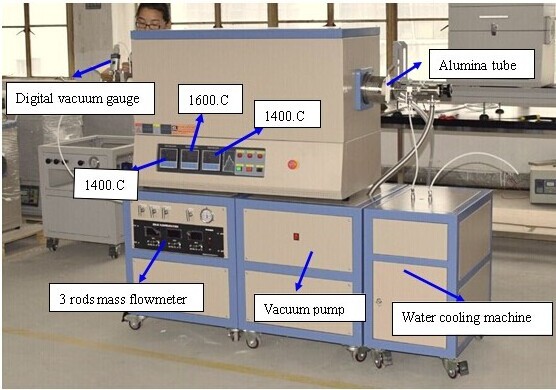

KJ-1600X-4-HVC2 is CE certified 4" diameter single zone alumina tube furnace with high vacuum pump system (up to 10 -5 torr) and 2 channel precision digital Mass flow-controllers, which can control two types of gases for CVD or diffusion and work up to 1600ºC.

CVD tube furnace

Specifications

| KJ-1700X series tube furnace |

Double layer steel casing with air cooling.

Two cooling fans inside to keep case temperature < 55°C. High purity Alumina refractory chamber Vacuum and gas mixing system is located in bottom Mobile cart with 4 wheel. Vacuum flange, gauge, valves, pipe and high vacuum pump are included for immediate use. |

|

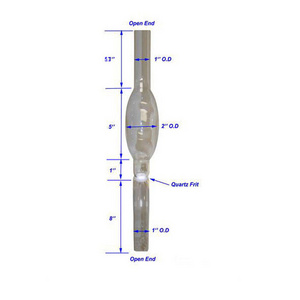

Material: High Purity Alumina

One processing tube is included with the furnace. 4.1 "OD x 3.625 " ID x 40 " L Alumina Ceramic Tube (99.8%) |

|

| 6KW | |

| AC 208-240V Single phase, 50/60Hz | |

| 8 pcs 1800°C grade MoSi2 heating element | |

|

Max. Heating Temp.: 1650°C

Continuous Working Temp.: 1600°C |

|

| <=5°C/min | |

|

Heating zone length: 457 mm (18")

Constant Temperature Zone length: 150 mm (6")(+/-1°C) |

|

|

PID automatic control via current limiting phase angle fired the resistor with 30 steps programmable segments.

Temperature accuracy: ±1°C Thermocouple: B type built inside the furnace |

|

|

One pair of stainless steel vacuum flange with:

- one digital vacuum gauge - two needle valves - one KF-25 connector and KF-25 to KF-40 adapter for the high vacuum station. - one 1/4" Swagelok tube connector |

|

| 550 x 380 x 520 | |

|

Reference picture of the tube furnace

|

|

| High Vacuum Station | 100~110W |

| AC 208-240V Single Phase, 50/60Hz | |

| 600(L) x 600(W) x 700(H), mm | |

|

Mobile cart size: 600 (L) x 600 (W) x 700(H), mm

Max. Loading: 600 Lbs on top Molecular pump control Panel : LCD digital Inside: Pfeiffer vacuum pump made in Germany Vacuum sensor is included |

|

|

One button operation - the diaphragm pump and the turbo molecular pump will start after pressing "start" button.

System controlled spinning speed - the controller will control the speed of the turbine spinning up and down according to the vacuum level and leaking rate of the reaction chamber. Self protection - the system will protect the pump from damage by overheating and over-current if the leaking rate of the reaction chamber is too high to achieve high vacuum. LCD screen - double lines parameters checking interface make the working easier to be handled. |

|

|

Nitrogen N2 33 L/s

Helium He 39 L/s (2340L/minute) Hydrogen H2 32 L/s |

|

| From 1000 mbar to <1E-7 mbar | |

| <1E-8 mbar (without any leaking ) | |

| Mass Flow Gas Control |

Made of 316 stainless steel

Gas mixing tank: Φ80X120mm Dimension: 600(L) x 600(W) x 700(H), mm Three Channels MFC control panel

The flow rate control range and number of gas routes are available for customization. Please contact us for detail information. |

| 18W per channel | |

| AC 208-240V, Single phase, 50/60Hz | |

| Please select the number of gas routes in the option bar to update the price | |

| Application Notes |

|

| Warranty | One year limited warranty |

| Compliance |

|

CVD tube furnace

Furnaces of cvd tube furnace in factory

CVD tube furnace

Packing and shiping

CVD tube furnace

our factory:

CVD tube furnace

Customer visit receipt photo

CVD tube furnace

company information

Kejia Electric Furnace is a manufacturer specializing in the production of heat treatment equipment. It has 10 years of research and development, production and sales experience. The company's products mainly include: muffle furnace, tube furnace, atmosphere furnace, vacuum furnace, CVD tube furnace system, dental furnace and so on. Widely used in powder metallurgy, vacuum brazing, annealing and other lingyu products sold to more than 30 countries and regions abroad, each product has CE certification, the use of products has received good feedback from customers, but we have not stopped research and upgrade The pace of the product. I look forward to our opportunity to cooperate.