- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V 50-60Hz, 380V/220V 50-60Hz

-

Place of Origin:

-

Zhejiang, China

-

Year:

-

2022

-

Brand Name:

-

LTPM CHINA

-

Dimension(L*W*H):

-

L1008*W952*H1785mm

-

Weight (KG):

-

500

-

Applicable Materials:

-

Liquid and ointment

-

Applicable Syringe Specifications:

-

0.5-80ml

-

Filling Accuracy:

-

≤±1-2%

-

Total Power:

-

3 KW

-

Compressed Air:

-

0.55-0.75Mpa 15L/S

-

Silicon oil assembly:

-

Japanese import customization

-

Number of injection needles:

-

1 needle

-

Feeding capacity:

-

0-180 units / min (Adjustable)

Quick Details

-

Production Capacity:

-

1800-2700, 2400-2700 p/h

-

Automatic Grade:

-

Automatic

-

Driven Type:

-

Electric

-

Voltage:

-

380V/220V 50-60Hz, 380V/220V 50-60Hz

-

Place of Origin:

-

Zhejiang, China

-

Year:

-

2022

-

Brand Name:

-

LTPM CHINA

-

Dimension(L*W*H):

-

L1008*W952*H1785mm

-

Weight (KG):

-

500

-

Applicable Materials:

-

Liquid and ointment

-

Applicable Syringe Specifications:

-

0.5-80ml

-

Filling Accuracy:

-

≤±1-2%

-

Total Power:

-

3 KW

-

Compressed Air:

-

0.55-0.75Mpa 15L/S

-

Silicon oil assembly:

-

Japanese import customization

-

Number of injection needles:

-

1 needle

-

Feeding capacity:

-

0-180 units / min (Adjustable)

The Marked Prices Of Our Products Are All Range Prices Of The Entire Product Series.

If You Need a Detailed Quotation, Please

Send An Inquiry

At The Bottom Of The Page.

Attention:

1.All prices and parameters shown above are automatically generated by the system, if you want to know the exact information, please click "Contact Supplier" to send mail to us.

2. Because of the time difference, we suggest that you can choose to

send us an inquiry

instead of online chat.

3.When sending us an inquiry or message, please tell us your Email or WhatsApp/Wechat/Skype .etc, then our sales manager can contact you quickly.

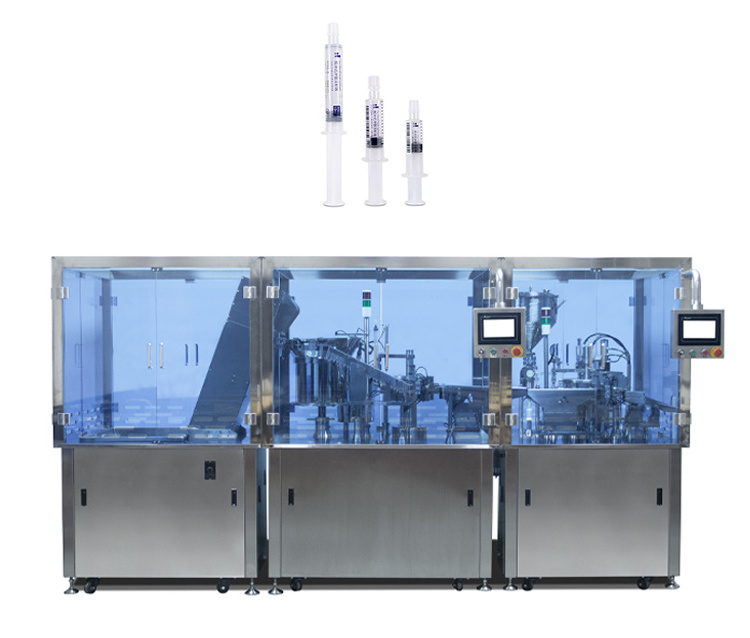

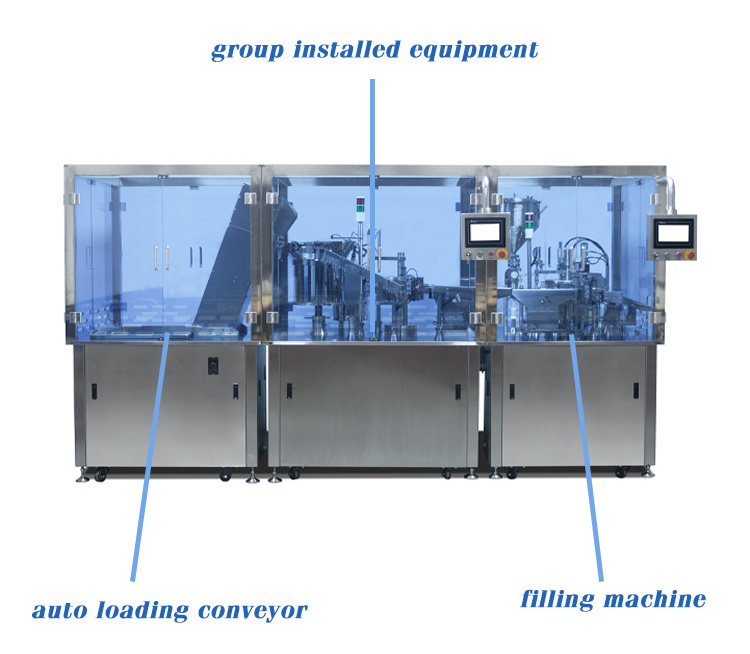

Product Description

This product is specially designed by our company for the filling of plastic syringes. It is an automatic packaging equipment for aseptic and efficient filling of syringes. The equipment runs smoothly, is simple to operate, and is equipped with intelligent detection devices, with high automation, high work efficiency, convenient maintenance, and the technology can reach the current domestic industry advanced level.

Technical Parameters

|

filling machine

|

|

|

|

Applicable materials

|

Water agent and ointment

|

|

|

Insyringe syringe applicable

|

0.5-80ml

|

|

|

Filling accuracy

|

≤±1-2%

|

|

|

Number of injection needles

|

One

|

|

|

productive power

|

1800-2700 branches / h

|

|

|

gross power

|

3KW

|

|

|

voltage

|

380V/220V 50-60Hz

|

|

|

group installed equipment

|

|

|

|

Applicable

package material

|

Custom plastic syringes

|

|

|

Insyringe syringe applicable

|

5-80ml

|

|

|

Silicon oil assembly

|

Japanese import customization

|

|

|

noise

|

≤ 60 decibels

|

|

|

production capacity

|

1800-2700 branches / h

|

|

|

gross power

|

3KW

|

|

|

voltage

|

380V/220V 50-60Hz

|

|

|

auto loading conveyor

|

|

|

|

Applicable package material

|

Custom plastic syringes

|

|

|

Insyringe syringe applicable

|

5-80ml

|

|

|

noises

|

≤ 60 decibels

|

|

|

Feeding capacity

|

0-180 units / min (Adjustable)

|

|

|

gross power

|

1.5KW

|

|

|

voltage

|

380V/220V 50-60Hz

|

|

|

physical dimension

|

L1100×W952×H1785mm

|

|

|

Max forming depth

|

12mm

|

|

|

Cutting frequency

|

0-25

|

|

|

Packing material

|

PVC/PE(0.2-0.4)×120mm

|

|

|

Capacity

|

1-50ml

|

|

|

Indtalled power

|

6.5Kw

|

|

|

Voltage

|

380V/50Hz

|

|

|

Machine’s weight

|

850Kg

|

|

|

Quter size(L×W×H)

|

3200×850×1400mm

|

|

If You Need Other Types Of Pellet Counting Machines,

Please Send An Inquiry To Get

Features

1.

This product is widely used for filling and capping of various types of plastic syringes, and special types can be customized.

2.

The surface is made of SUS 304 stainless steel, and the contact parts are made of SUS 316L stainless steel and medical silicon rubber, which fully meets the requirements of GMP specifications.

3.

The ceramic plunger pump realizes quantitative filling, is resistant to acid and alkali corrosion, wear-resisting and high temperature, and has high filling accuracy.

4.

The conveying and sorting of the caps is realized by the vibratory feeder, which adopts the SUS 316L stainless steel clean plate, which has a bright surface treatment and no clean dead corners.

5.

Adopting internationally well-known electrical components, implementing non-interference modular control, all synchronous actions are controlled by servo motors, which are accurate and reliable, and easy to operate.

6.

The operation of the motor is controlled by the PLC programming controller, and the human-computer interaction interface monitors and displays the working status of each station in real time, and automatically alarms and displays the fault location in real time, and the fault prompts.

7.

Fully automatic operation, automatic filling, automatic organizing and automatic capping.

8.

The method of filling the syringe head can eliminate the air inside the syringe to the greatest extent and improve the qualification rate.

9.

Modular design, easy to locate, easy to expand, can be used as a stand-alone machine or connected to hoist, assembly machine, rotary rod machine, labeling machine and other equipment to form a production line.

10.

Optional 100-level laminar flow hood to achieve high-demand clean production.

Product Details

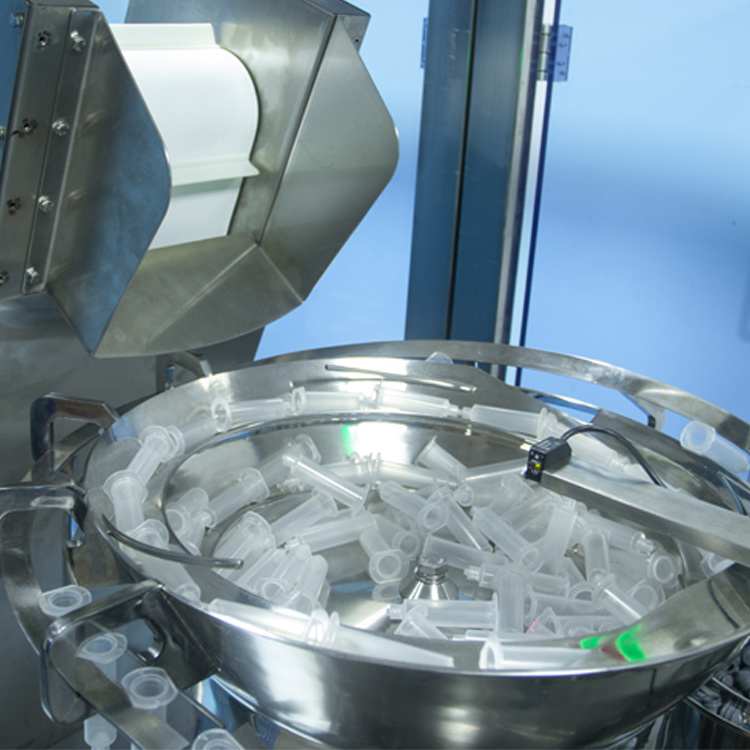

Auto Loading Conveyor

Auto Loading

Just place the full box of syringes in the conveyor to save labor.

Group Installed Equipment

Syringe tube loading guider

Syringe sort of vibrating plate will sort of the syringe tubes and send to the loading guider one by one, loading guider will send syringe tub into turn table.

Assembling Station

Assembling equipment, Japanese import customization Silicon oil assembly.

Filling Machine

Filling Station

Controlled by the perlistaltic pump,high precision and easy clean.

Capping Station

Automatic Arranging thelids by vibrating disk(customby the dimension of your syringe).Automatic capping the lid on syringe.

Output Station

Automatic output finish product.

If You Want To Know More About The Machine Details, Please Send An Inquiry To Get It

Final Product

Related Products

Hot Searches