- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Automatic glue dispensing machine

-

X/Y/Z Working Range:

-

300*300*100

-

Voltage:

-

110/220V 50/60HZ

-

Running accuracy(mm):

-

0.01/Axis

-

Repeat accuracy(mm):

-

±0.005/Axis

-

Work condition:

-

Temperature 0-40°C / Humidity 20-90%

-

Glue:

-

One component

-

Dispensing Volume:

-

10-100g/5s(based on 1:1 glue proportion)

-

Dispensing Precision:

-

Glue Amount±1%, Glue Proportion±1%

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BBA

-

Weight (KG):

-

65

-

Product name:

-

Automatic glue dispensing machine

-

X/Y/Z Working Range:

-

300*300*100

-

Voltage:

-

110/220V 50/60HZ

-

Running accuracy(mm):

-

0.01/Axis

-

Repeat accuracy(mm):

-

±0.005/Axis

-

Work condition:

-

Temperature 0-40°C / Humidity 20-90%

-

Glue:

-

One component

-

Dispensing Volume:

-

10-100g/5s(based on 1:1 glue proportion)

-

Dispensing Precision:

-

Glue Amount±1%, Glue Proportion±1%

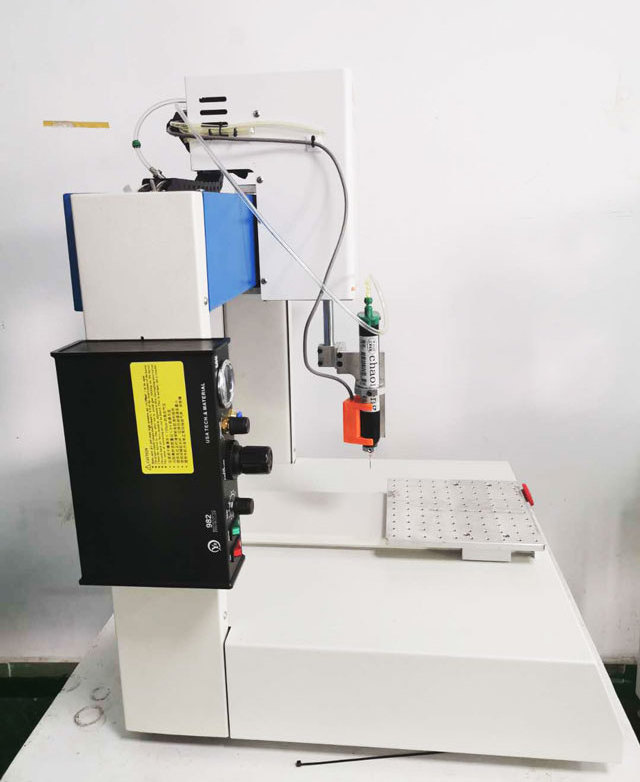

Automatic glue dispenser machine is to spray or dispense the glue automatically for bonding, filling, coating, sealing, filling, dripping, linear/arc/round coating, etc. in the product process. BBA Dispensing Systems has the capability to integrate the gluing system with XYZ movements for precised glue dispensing. Adhesive epoxy dispensing system,AB glue dispensing equipment,liquid dispenser robot is for easy programming with teaching pendant, is applicable for various glue types as Silicon,AB adhesive,epoxy resin adhesive, hot glue,transparent paint and for wide application of electronic products, home appliance etc. BBA can fabricate robotic glue dispenser machine to meet your product requirements.

Products Description

Machine external accessories

Detailed operating instructions & videos prepared to teach you step by step

Customization available

Specification of glue dispensing machine series

|

Model

|

BBA-331DJ

(Single Y platform)

|

|

BBA-5331DJ

(Double Y platform)

|

|

Customized

|

||||

|

Power supply

|

AC110/220V 50/60HZ

|

|

|

|

|

||||

|

Stroke

|

X

|

300mm

|

X

|

500mm

|

To order

|

||||

|

|

Y

|

300mm

|

Y1/Y2

|

300mm

|

|

||||

|

|

Z

|

100mm

|

Z

|

100mm

|

|

||||

|

Maximum load weight

|

8KG (for work platform)

|

|

|

|

To order

|

||||

|

Running track

|

Dotted, line, arcs and irregular paths

|

|

|

|

|

||||

|

Moving speed

|

10-800mm/S

|

|

|

|

|

||||

|

Air pressure

|

0.5-0.7Mpa

|

|

|

|

|

||||

|

Position accuracy

|

±0.05mm/axis

|

|

|

|

|

||||

|

Program capacity

|

999 groups/1000 points per group

|

|

|

|

|

||||

|

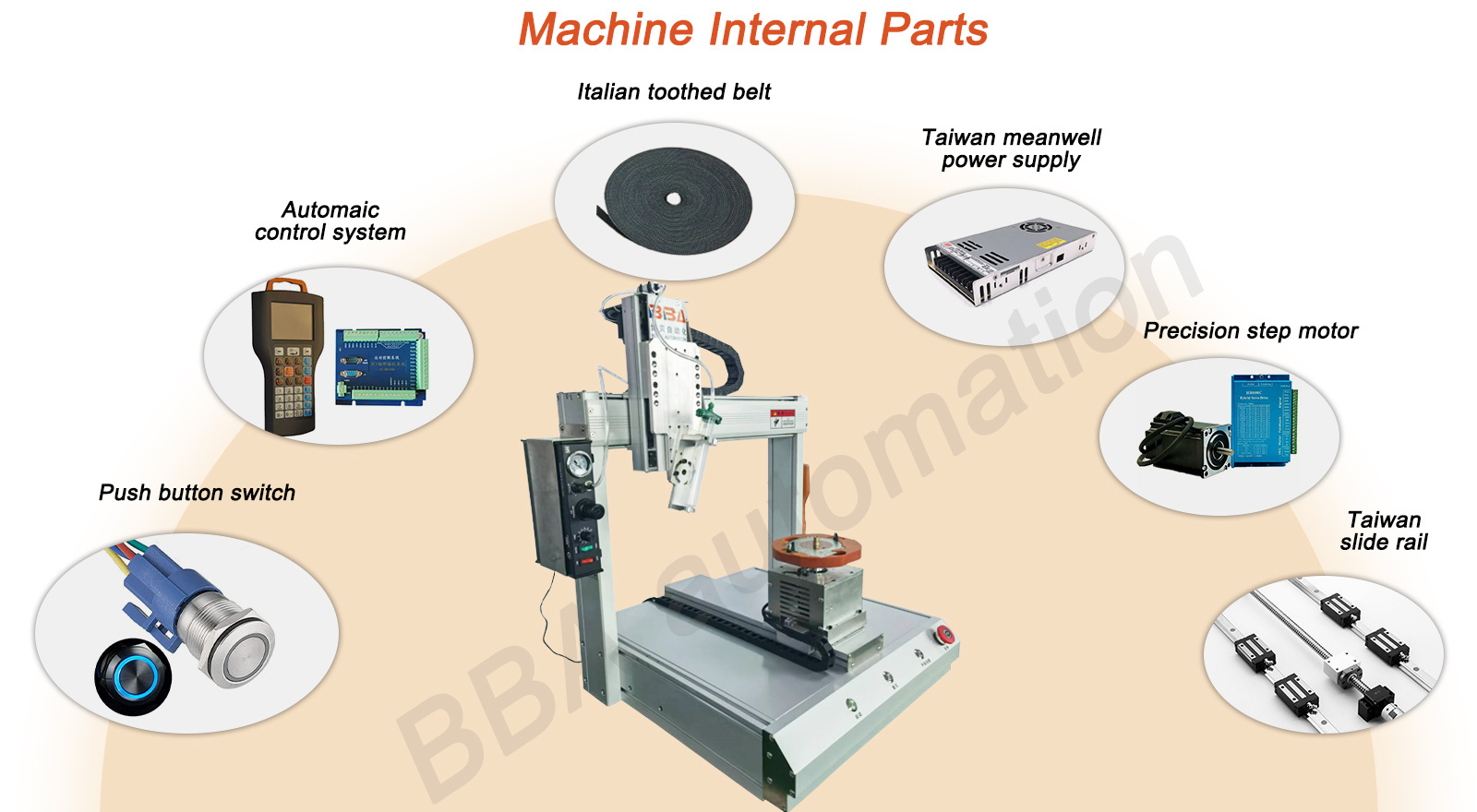

Motor system

|

Micro precision stepping motor

|

|

|

|

|

||||

|

Transmission mode

|

Precision toothed belt+guide rail

|

|

|

|

|

||||

|

Minimum glue amount

|

0.01ml

|

|

|

|

|

||||

|

Control panel

|

Teaching pendant with display screen

|

|

|

|

|

||||

|

Work environment

|

Temperature: 5-40℃ Humidity: 20-90%

|

|

|

|

|

||||

|

Weight

|

60kg

|

|

100kg

|

|

To order

|

||||

|

External machine size

(L*W*H)

|

700*630*700mm

|

|

820*730*700mm

|

|

To order

|

||||

Applicable glue type

Customer case

Packing & Delivery

Hot Searches