2. Respond within 24 hours and proceed to deal with the problem.

3. 1 year free repair service (no-human damage only).

4. Overall machining solution provided

|

Project

|

Unit

|

HTC

40Sm/500

|

||

|

Max. cutting dia.

|

mm

|

Φ350

|

||

|

Max.cutting length

|

mm

|

450

|

||

|

Max. swiming dia.over bed

|

mm

|

Φ560

|

||

|

Max. swiming dia.on slide

|

mm

|

Φ400

|

||

|

Spindle

|

|

|

||

|

Spindle nose model

|

|

A2-8

|

||

|

Front bearing inner dia.

|

mm

|

120

|

||

|

Spindle taper and hole size

|

|

1:20;Φ90

|

||

|

Dia. of spindle hole

|

|

Φ80

|

||

|

Max.bar dia.

|

mm

|

Φ65

|

||

|

Standard chuck dia.

|

inch

|

10

|

||

|

Spindle speed range

|

r/min

|

4000

|

||

|

Rated spindle torque

|

N·m

|

170(800r/min)

|

||

|

Spindle Max. torque

|

N·m

|

280(600r/min)

|

||

|

Main motor output power continuous/15 min.

|

kW

|

15/18.5

|

||

|

X/Z axis

|

|

|

||

|

X/Z axis rapid movement

|

m/min

|

20

|

||

|

X axis travel

|

mm

|

220

|

||

|

Z axis travel

|

mm

|

510

|

||

|

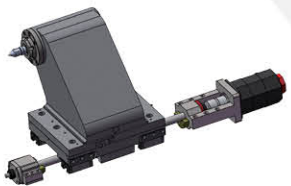

Tailstock

|

|

|

||

|

Tailstock travel

|

mm

|

350

|

||

|

Tailstock drive method

|

|

Saddle drag

|

||

|

Tailstock sleeve travel

|

mm

|

100

|

||

|

Tailstock sleeve dia.

|

mm

|

Φ100

|

||

|

Tailstock taper hole taper

|

Morse

|

MT-4

|

||

|

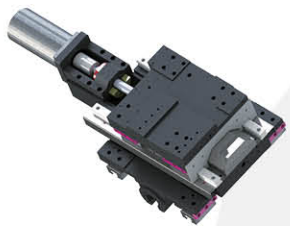

Turret

|

|

|

||

|

Turret typle

|

|

Horizontal 12-station power turret

|

||

|

Center height

|

mm

|

80

|

||

|

Turret indexing repeat positioning accuracy

|

Sec.

|

±1.6

|

||

|

Tool size

|

mm

|

25

|

||

|

If could choose tool nearby

|

|

yes

|

||

|

Power tool holder interface

|

|

BMT55

|

||

|

Max. drilling capacity

|

mm

|

16×0.2

|

||

|

Max. milling capacity

|

mm

|

14×10×40

|

||

|

Max. tapping capacity

|

mm

|

M12×1.5

|

||

|

Others

|

|

|

||

|

Distance between spindle center and floor

|

mm

|

1050

|

||

|

Machine tool net weight

|

kg

|

4300

|

||

|

Overall dimensions(LxWxH)

|

mm

|

2870×1920×2000

|

||

|

Note: The parameters provided in the table are for reference only. If there is any change, please refer to the actual product.

|

|

|

||