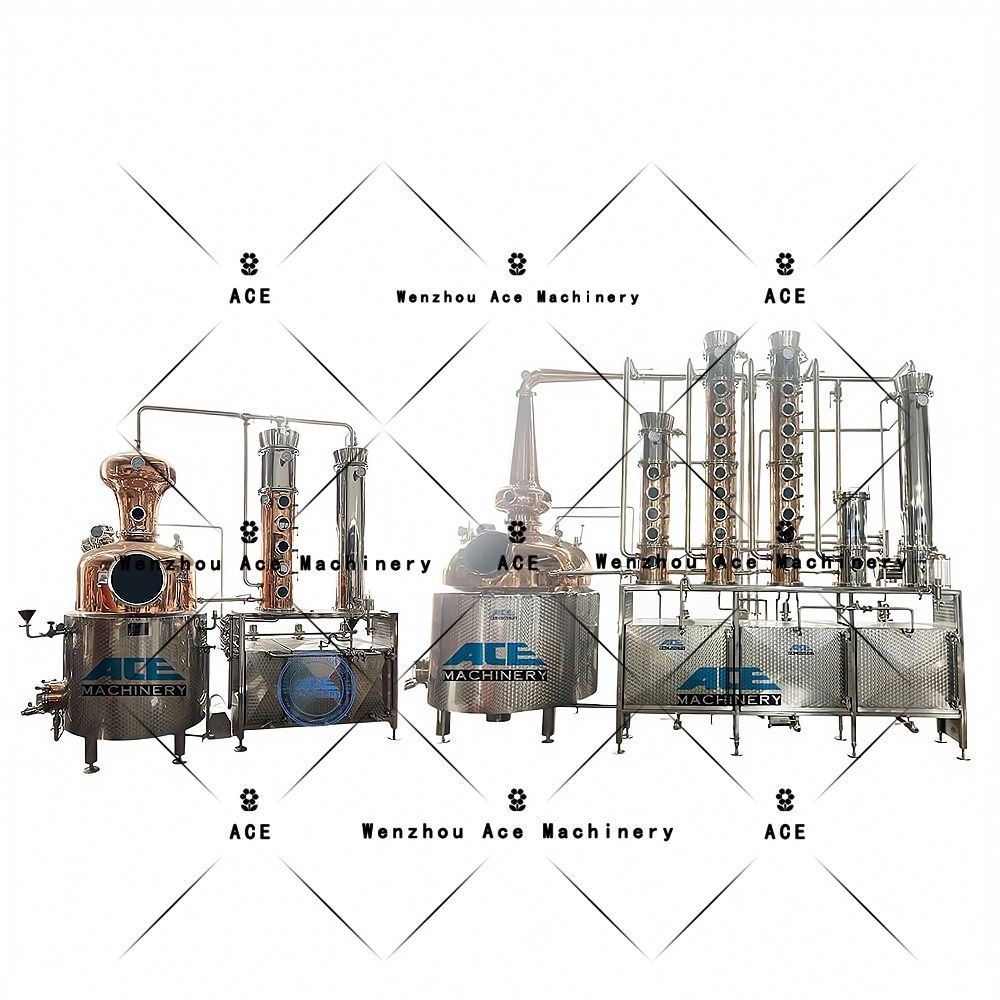

8. One

machine and dual usage. It could make whiskey, rum, brandy, tequila etc. By once running of the distiller. By twice distillation the alcohol content will up to 95% and it can also remove methanol.

9. The

equipment is made of stainless steel and copper, with beautiful appearance and high sanitary level.