1. Big Volecity- Reducing Ratio:Ratio of single-stage speed-reducing is 1/11-1/87; Ratio of double stage speed-reducing is 1/112-1/5133;Ratio of three-stage speed-reducing is 1/2057-1/446571;more-stages can be combined according to the requirement.

2. High driving efficiency:Due to adopting rolling engagement in falling-in part, the driving efficiency can reach above 90%.

3. Small in size, light weight: with compacted structure,small size and light weight. Due to adopting the principle of planet driving so that the input and output shaft in the same axis which will integrated with the motor.

4. Long service life: Has good resistance to abrasion because the main driving engaging parts are made of bearing steel and applying rolling friction.

5. Stable running: for most driving procedure, we adopt multi-teeth falling-in. Then the running will be stable with low noise.

6. Convenient dismounting:reasonable structure and design.

7. Strong overloading ability,anti-compact,suitable for frequently start and double-side rotation.

- Product Details

- {{item.text}}

Quick Details

-

Output Speed:

-

14-280rpm

-

Warranty:

-

1 year

-

Weight (KG):

-

200 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tianqi

-

Pole:

-

one two three four six Stage

-

Ratio:

-

11-87

-

Housing Material:

-

Cast Iron

-

Working temperature:

-

-40~45℃

-

Application:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

-

Process:

-

Carburizing, Nitriding , Grinding

-

Efficiency:

-

94%~98%

-

Mounting Position:

-

Horizontal,Vertical,Flange

-

Type:

-

XLD BLD concrete mixer speed reducers cycloidal gearbox vertical shaft

-

Certification:

-

speed reducers cycloidal gearbox gear box motor

Quick Details

-

Gearing Arrangement:

-

Cycloidal

-

Output Torque:

-

70-1700 N.m

-

Input Speed:

-

12-136rpm

-

Output Speed:

-

14-280rpm

-

Warranty:

-

1 year

-

Weight (KG):

-

200 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tianqi

-

Pole:

-

one two three four six Stage

-

Ratio:

-

11-87

-

Housing Material:

-

Cast Iron

-

Working temperature:

-

-40~45℃

-

Application:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

-

Process:

-

Carburizing, Nitriding , Grinding

-

Efficiency:

-

94%~98%

-

Mounting Position:

-

Horizontal,Vertical,Flange

-

Type:

-

XLD BLD concrete mixer speed reducers cycloidal gearbox vertical shaft

-

Certification:

-

speed reducers cycloidal gearbox gear box motor

Product Overview

PROFESSIONAL MANUFACTURE

—— SINCE 1995

TIANQI

Cyloidal Pin Wheel Planetary gear box speed reducer

TIANQI Cyloidal Pin Wheel Planetary gear box speed reducer

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light

industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear motor reducer, K series spiral bevel gear reducer motor, NGW, P series Planetary Gear reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer box, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, ZLYJ Extruder Gearbox etc. Meanwhile, map sample processing business can be undertaken.

industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear motor reducer, K series spiral bevel gear reducer motor, NGW, P series Planetary Gear reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer box, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, ZLYJ Extruder Gearbox etc. Meanwhile, map sample processing business can be undertaken.

FEATURES AT A GLANCE

Cyclo Cyloidal Pin Wheel Planetary gear box speed reducer

PRODUCT SPECIFICATIONS

|

MODEL

|

X Series

|

B Series

|

JXJ Series

|

||

|

SIZE

|

XWD XWED XLD XLED

|

BWD BWED BLD BLED BWY BWEY BLEY

|

JXJL JXJW JXJLED JXJWED

|

||

|

RATIO

|

Single Stage: 11 17 23 29 35 43 59 71 87

Double Stage: 121 187 289 319 473 595 731 741 1003 1225 1505 1849 2065 2537 3481 5133

|

|

|

||

|

SPEED RPM

|

Single Stage: 136/91 88/59 60/40 52/35 43/29 38/23 25/17 21/14 17/12

Double Stage: 12.4 8 5.2 4.7 3.2 2.5 2 1.8 1.5 1.2 1 0.8 0.7 0.6 0.4 0.3

|

|

|

||

|

MOTOR POWER

|

0.55kw 0.75kw 1.5kw 2.2kw 3kw 4kw 5.5kw 7.5kw 11kw 15kw 18.5kw 22kw 30kw 37kw 45kw 55kw

|

|

|

||

TIANQI Cyloidal Pin Wheel Planetary gear box speed reducer

Gear Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm reducer, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery,electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. XLD BLD 5.5 3 concrete mixer speed reducers cycloidal gearbox vertical to horizontal shaft gear box with motor .

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery,electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. XLD BLD 5.5 3 concrete mixer speed reducers cycloidal gearbox vertical to horizontal shaft gear box with motor .

|

Phase

|

Single/Three Phase

|

|

|

|

|||

|

Pole

|

2

|

4

|

6

|

8

|

|||

|

Power(kw)

|

0.18-375KW

|

|

|

|

|||

|

Frequency(hz)

|

50/60

|

|

|

50/60

|

|||

|

Speed(rpm)

|

3000

|

1500

|

1000

|

750

|

|||

PRODUCT CONFIGURATION

Working principle of gear reducer

When the output speed of the motor of the gear reducer is input from the driving shaft, the small gear of the reducer will move.

The large gear is linked with the small gear, so the movement of the small gear will drive the movement of the large gear.

The number of teeth is more than the number of teeth on the pinion, so the speed of the big gear will be slower than that of the pinion, and then output through the output shaft of the big gear, thus playing the role of output deceleration.

Gear reducer application range

The gear used in the gear reducer is carbon-quenched and high-strength low-carbon alloy steel, which has a high design and manufacturing process, and also has the characteristics of good foundation and high precision of the tooth surface.

Gear reducers are generally used in low-speed and high-torque transmission equipment,it have extremely common applications in the transmission and drive fields of textile, printing and dyeing, light industry, food, metallurgy, mining, petroleum,chemical, construction, transportation, machinery and other industries.

The role of gear reducer

1. Slow down. Deceleration In industrial production, it is often necessary to use different frequency rates to produce operations. The gear reducer changes the frequency conversion deceleration of the equipment during operation through a certain function.

2. Change the torque. The gear reducer achieves the purpose of changing the speed of the equipment by changing the torque. Different equipment has different maximum torque values and cannot exceed that value.

3. Reduce inertia. The gear reducer will reduce the inertia of the target machine while working.

Working principle of gear reducer

When the output speed of the motor of the gear reducer is input from the driving shaft, the small gear of the reducer will move.

The large gear is linked with the small gear, so the movement of the small gear will drive the movement of the large gear.

The number of teeth is more than the number of teeth on the pinion, so the speed of the big gear will be slower than that of the pinion, and then output through the output shaft of the big gear, thus playing the role of output deceleration.

Gear reducer application range

The gear used in the gear reducer is carbon-quenched and high-strength low-carbon alloy steel, which has a high design and manufacturing process, and also has the characteristics of good foundation and high precision of the tooth surface.

Gear reducers are generally used in low-speed and high-torque transmission equipment,it have extremely common applications in the transmission and drive fields of textile, printing and dyeing, light industry, food, metallurgy, mining, petroleum,chemical, construction, transportation, machinery and other industries.

The role of gear reducer

1. Slow down. Deceleration In industrial production, it is often necessary to use different frequency rates to produce operations. The gear reducer changes the frequency conversion deceleration of the equipment during operation through a certain function.

2. Change the torque. The gear reducer achieves the purpose of changing the speed of the equipment by changing the torque. Different equipment has different maximum torque values and cannot exceed that value.

3. Reduce inertia. The gear reducer will reduce the inertia of the target machine while working.

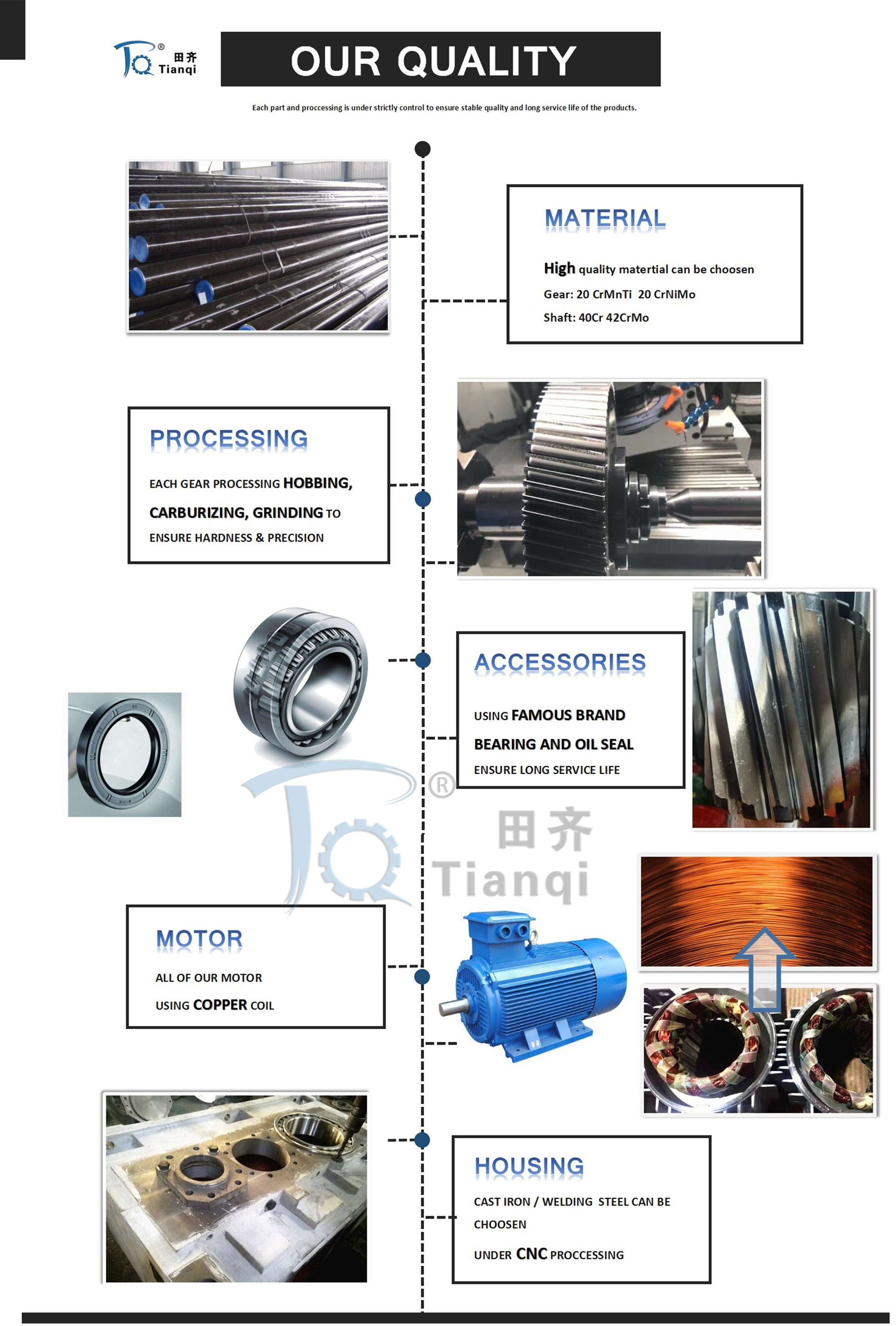

20CrMnTi Hard Tooth Gear

Copper Coil High Quality Electric Motor

Famous Brand Bearings

Hot Searches