Weighing process: The weighing module is matching with matching instruments.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2500*260*240 cm

-

Weight:

-

1800 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V

-

Power:

-

60kw--240kw

-

Application:

-

Food Processing Machine

-

After-sales Service Provided:

-

Service Overseas

-

Function:

-

Multi-function

-

Name:

-

puff snack machine

-

Material:

-

corn, grain, rice , wheat powder

-

Raw material:

-

304 Sainless Steel

-

Final product:

-

snack food

-

Feature:

-

twin screw extruder

-

Certificate:

-

ISO9001, ce

-

Keywords:

-

Easy Operate High Productivity

Quick Details

-

Machinery Capacity:

-

100-500 kg/h

-

Brand Name:

-

MT

-

Year:

-

2024

-

Dimension(L*W*H):

-

2500*260*240 cm

-

Weight:

-

1800 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V

-

Power:

-

60kw--240kw

-

Application:

-

Food Processing Machine

-

After-sales Service Provided:

-

Service Overseas

-

Function:

-

Multi-function

-

Name:

-

puff snack machine

-

Material:

-

corn, grain, rice , wheat powder

-

Raw material:

-

304 Sainless Steel

-

Final product:

-

snack food

-

Feature:

-

twin screw extruder

-

Certificate:

-

ISO9001, ce

-

Keywords:

-

Easy Operate High Productivity

puffing machine puff 9000 tornado puff millet puff machine cheese puffs making machine

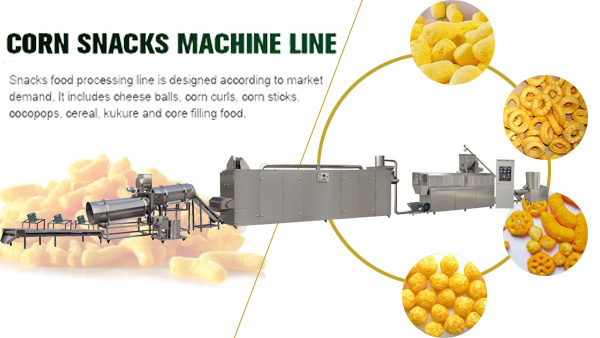

Products Description

Fully automatic Twin Screw Extruder Corn Puff Making Machine .

Raw materials:

Usually we will offer our customers some basic formula for corn puffing, food extruding snack food production. The raw materials for corn puff snacks food production can be

corn, rice, wheat, oat, barley

flour etc.

Application:

with strong R & D ability, our engineers offer suitable proposal as customers' requirement, factory size, and local investment. This corn puffing snacks food production line can be used to produce

various type snacks by changing dies, such as cheese ball,

ball, tube, stick, ring, fruit loop, star, wheel, flower, star and heart shape

etc.The shape, size, flavor of snacks can be customized as requirement.

Capacity:

100-800kg/hr

Features.

1) We can offer customers packing machine for this corn puffs snacks processing line. This line is multi-functional. Many different shapes of corn puffs can be produced by this puffed snacks production line.

2) Final products--corn puffs will be crispy, contains abundant compound carbohydrates and dietary fibre, micro-elements.

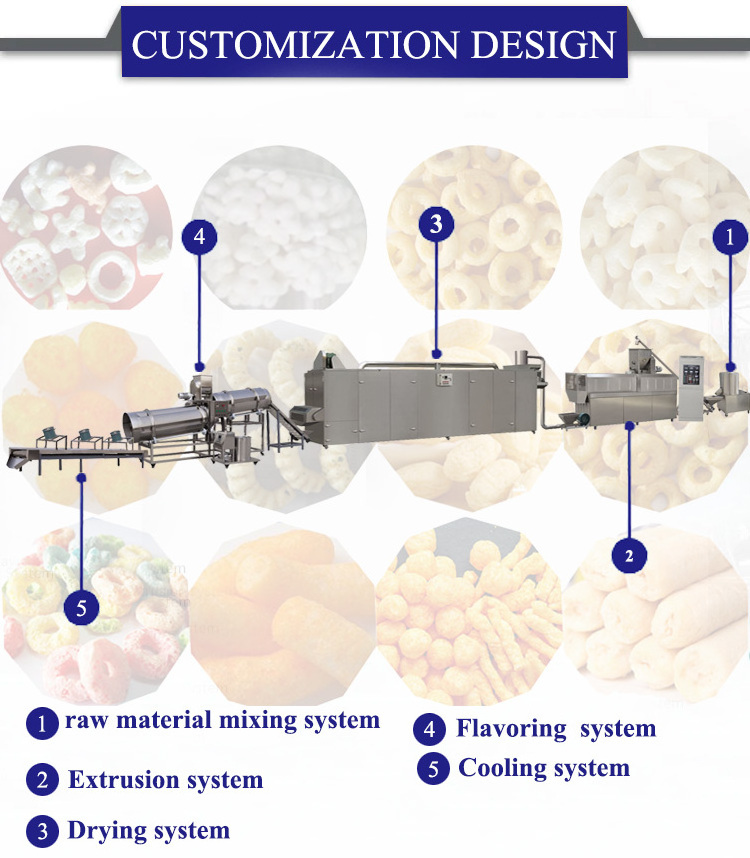

Process Flow

With OEM and ODM design, we promise to offer customers suitable proposal according to his factory size, which includes factory layout, Production line drawing, Turn-key solution from material grinding to final packing system.

Flow Chart of

puffed snacks making machine

: Materials preparation--Material batching--Extruding--drying--Coating or flavoring--Cooling--Packing--Stacking

|

Model

|

Corn puff machine MT65

|

Corn puff machine

MT70

|

Corn puff machine MT85

|

Corn puff machine

MT100

|

|

Installed Power

|

130KW

|

180KW

|

220KW

|

240kw

|

|

Real Consumption

|

95KW

|

120KW

|

130KW

|

160kw

|

|

Capacity

|

120-150KG/HR

|

200-300 KG/HR

|

300-500 KG/HR

|

600-800kg/hr

|

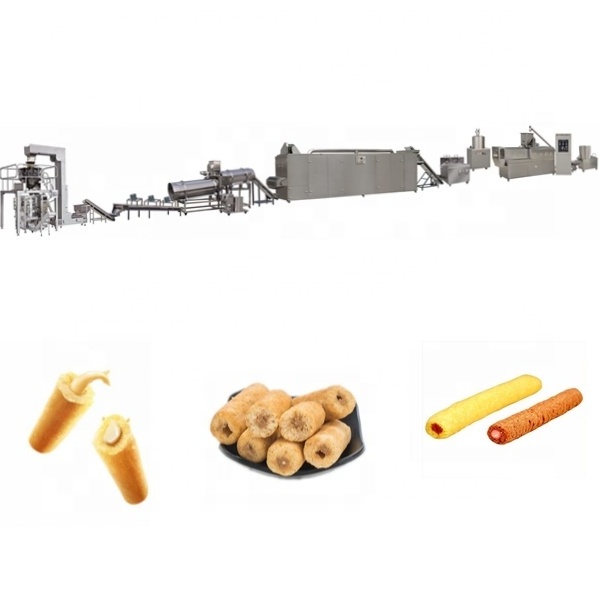

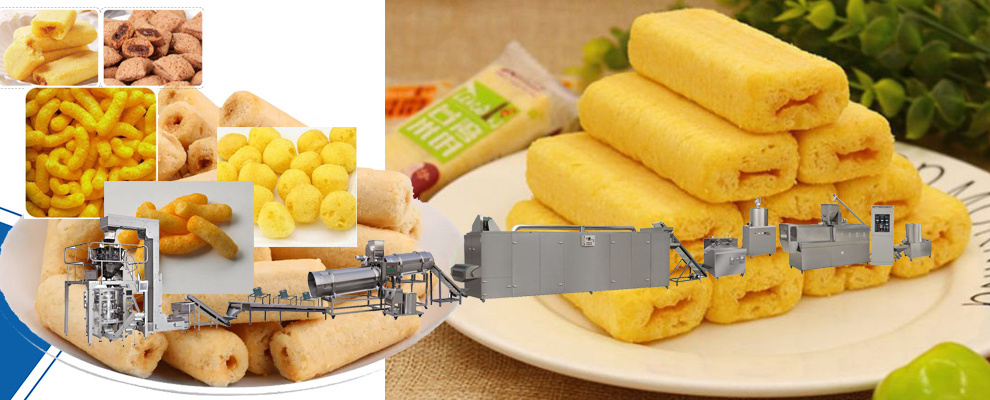

Core filling puffing snacks processing line.

With adding an core filling machine, and a cutting machine, flavored corn core filling snacks will be produced by this line.

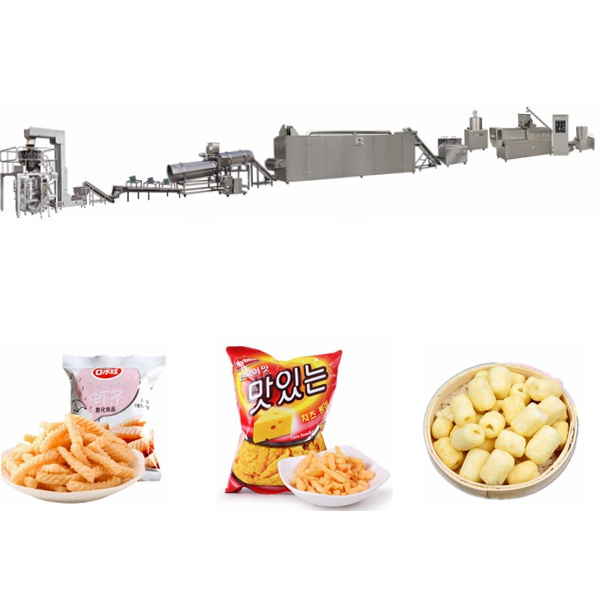

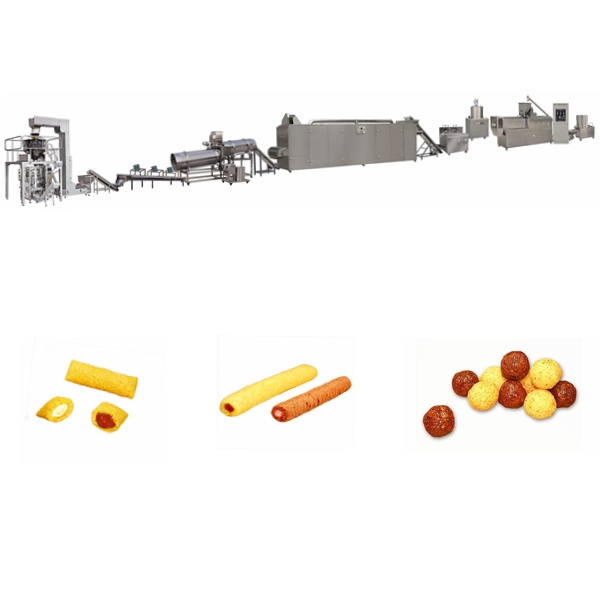

Sample Pictures

Corn puffs snack food processing line can produce puffing snacks with different shapes, such as,

cheese ball, ball, tube, stick, ring, fruit loop, star, wheel, flower, star and heart. After adding color agents and flavoring, very unique taste corn puffed snacks will be met.

This production line characterizes with reasonable structural design, special material, self- cleaning performance and stability.

Easy operation, accurate parameter. The final corn puffed snacks are very tasted. which is popular in market.

Easy operation, accurate parameter. The final corn puffed snacks are very tasted. which is popular in market.

Machine Details

Mixing machine for corn puffs snacks

Equipment: Mixing raw materials and water equally before entering into the main machine of corn puffed snacks production.

MT70 Twin Screw Snacks Extruder

This is the main machine of corn snacks production line, which is used to extruding raw materials. It adopts frequency speed controlling system with high automatic and stable performance.

Automatic lubricating, cooling, which guarantee machine running safely, stable and reliable.

The extruding corn grits are high quality, and good texture.

Corn puffs snack drying machine

The Heating source can be electric, steam and gas. All can be designed according to customer's local conditions and requirement.

Usag

e: drying the moisture of humid air out of extruding products, reducing the heat waste.

Drying puffed snacks after extruding or coating for next procedure.

Double drum flavoring line

It consists of two tumblers. sugar melting and spraying nozzle and elevator.

The sugar will be melted and sprayed onto the surface of corn puffs. This device can equally spray and coat oil, melt sugar, liquid and flour flavor on product surfaces for improving the appearance and taste.

Capacity is as Extruder.

Packing machine.

Process: including automatic weighing, sealing, marking, coding and packing.

Packing forms: bag filling, fully automatic packing.

Features: high precision, high speed, long service life, good stability.

Automatic measurement, designed for vibration feeding, electronic pad weighing, to overcome the error of measurement caused by the change of material proportion.

Hot Searches