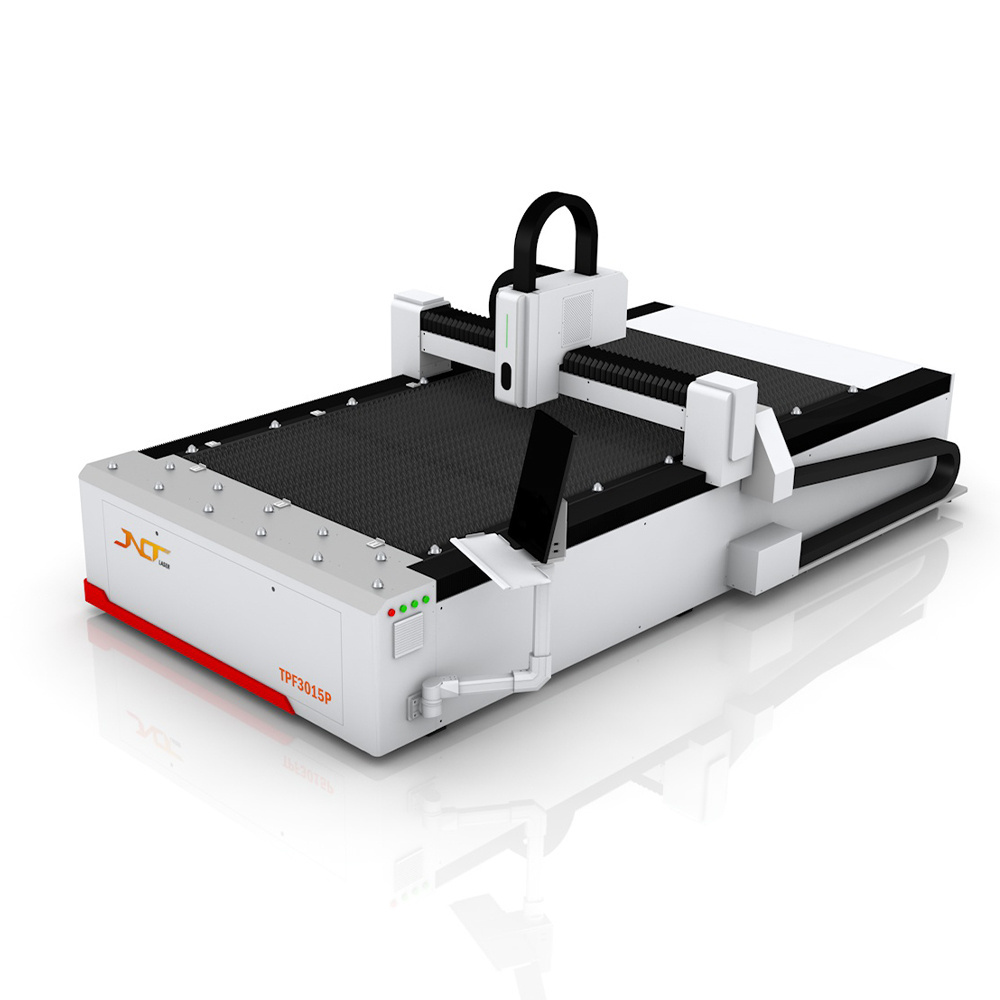

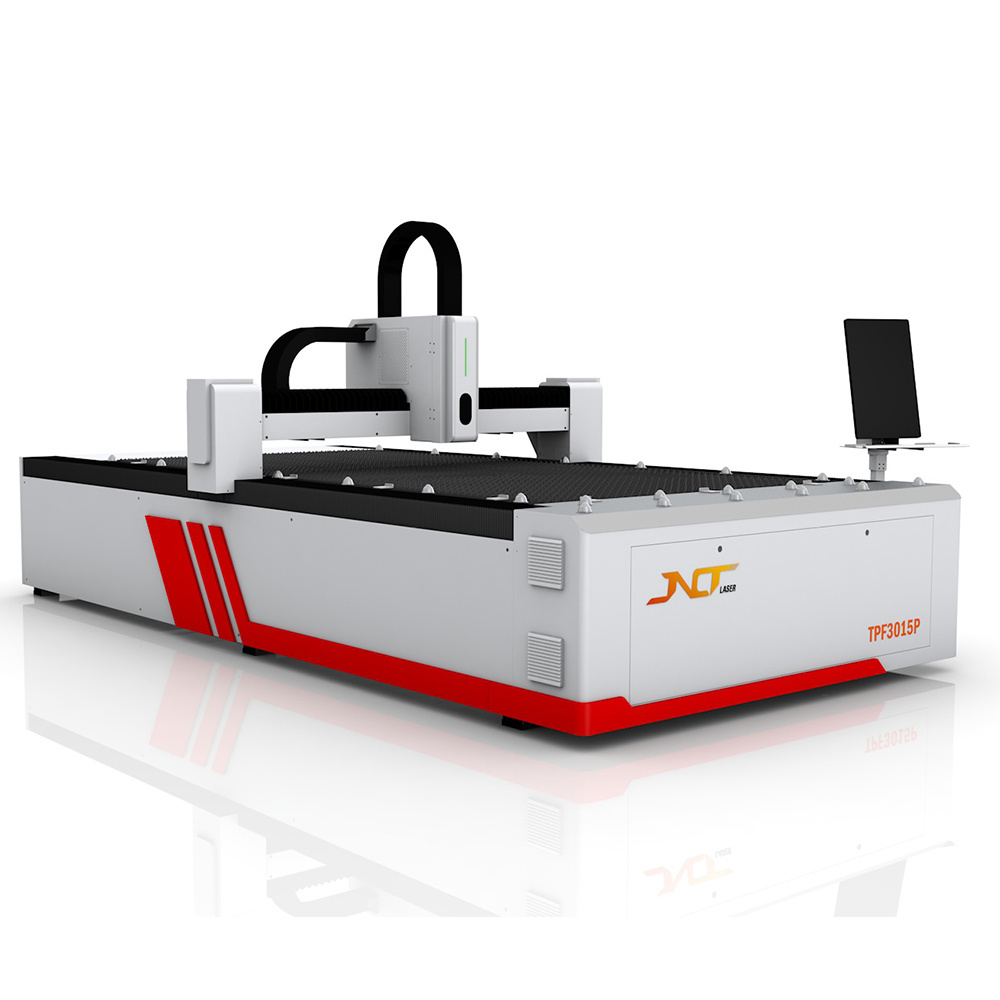

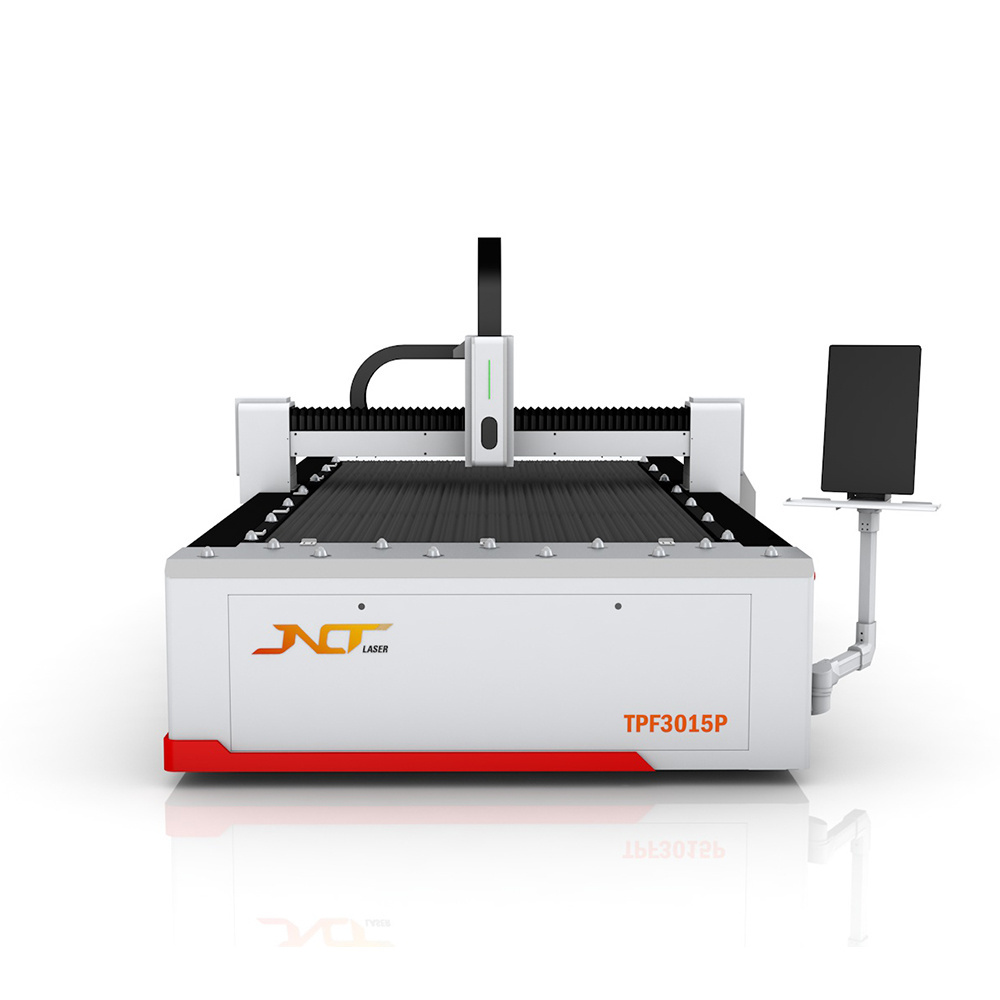

This TPF-3015P model laser cutter is our best competitive in price one with high cost performance, perfect combination of high precision and high speed, achieves high quality metal cutting, it’s a best choice if you don’t know how to choose a right cheapest metal cutting fiber laser, and now this machine is for sale with big discount, golden time to ask for a quotation, use this cheap 1000w laser cutter price to start a small business.

This best laser cutter for small business has widely field in application Industry: Electric power, automobile manufacturing, mechanical equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, automobile decoration, sheet metal production, lighting hardware, display equipment, precision parts, hardware products and other industries; Application materials : This 1000w laser cutter can cut a variety of metal plates and pipes (pipe cutting device can be added), mainly suitable for stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass plate, aluminum plate, manganese steel, various alloy plates, rare fast cutting of metal and other materials;

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

BOCHU

-

Cutting Thickness:

-

Depend on metal type

-

Control Software:

-

cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JNCTlaser

-

Weight (KG):

-

2000 KG

-

Product name:

-

Fiber laser cutting machine

-

Laser head:

-

Switzerland Raytools

-

Control system:

-

Cypcut Control System

-

Driving system:

-

Servo Motor

-

Transmission:

-

Gear Rack

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

After-sales Service Provided:

-

Online support

-

Cutting materials:

-

Stainless Steel Carbon Steel

-

Certification:

-

ce

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

35m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

BOCHU

-

Cutting Thickness:

-

Depend on metal type

-

Control Software:

-

cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JNCTlaser

-

Weight (KG):

-

2000 KG

-

Product name:

-

Fiber laser cutting machine

-

Laser head:

-

Switzerland Raytools

-

Control system:

-

Cypcut Control System

-

Driving system:

-

Servo Motor

-

Transmission:

-

Gear Rack

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

After-sales Service Provided:

-

Online support

-

Cutting materials:

-

Stainless Steel Carbon Steel

-

Certification:

-

ce

High quality 1000w 1500w 2000w laser cutter MAX laser power Fiber laser metal cutting machine price

Product Overview

Features at a glance

Best Laser Cutter For Small Business-1000w Cheap Laser Cutter

JNCTlaser 1000w fiber laser cutting machine model TPF-3015P

is the best laser cutter for small business. This cheap laser cutter uses the world top brand parts, Raytools fiber laser head, the laser head can automatically focus, and imported Japan FUJI servo motors and drives, high precision, high speed, large torque, performance is stable and durable, ensure the high speed operation of the whole machine. Chinese top brand fiber laser source RAYCUS, high power, high precision. Top brand control system: Cypcut control system, with automatic layout optimization.

Left view

Front view

Right view

Machine Specification

|

1000w 2000w 3000w Laser Cutting Machine Comparation

|

|

|

||

|

2000W Laser Cutting Machine Speed

|

1000W Laser Cutting Machine Speed

|

3000W Laser Cutting Machine Speed

|

||

|

Carbon Steel: 28m/min

|

Carbon Steel: 24m/min

|

Carbon Steel: 35m/min

|

||

|

Stainless Steel: 28m/min

|

Stainless Steel: 24m/min

|

Stainless Steel: 35m/min

|

||

|

Aluminum Sheet: 25m/min

|

Aluminum Sheet: 10m/min

|

Aluminum Sheet: 43m/min

|

||

|

Cooper Sheet: 16m/min

|

Cooper Sheet: 10m/min

|

Cooper Sheet: 35m/min

|

||

|

2000w Laser Cutter Work Thickness

|

1000w Laser Cutter Work Thickness

|

3000w Laser Cutter Work Thickenss

|

||

|

Carbon Steel: 10mm

|

Carbon Steel: 16mm

|

Carbon Steel: 20mm

|

||

|

Stainless Steel: 5mm

|

Stainless Steel: 8mm

|

Stainless Steel: 10mm

|

||

|

Aluminum Sheet: 3mm

|

Aluminum Sheet: 5mm

|

Aluminum Sheet: 8mm

|

||

|

Carbon Sheet: 3mm

|

Carbon Sheet: 5mm

|

Carbon Sheet: 8mm

|

||

Machine Configurations

Sample

Application

Packing and Shipping

Packing & Shipping

To ensure this laser cutter as the best laser cutter for small business, we pay more attention to the package to keep the transportation safety.

1. We will prepare a Iron base to ensure the stability of the machine and the convenience of loading and unloading containers;

2. We will disassemble the laser source , and the laser source will be separately packed in a wooden box. At the same time, auxiliary accessories such as chillers and fans are packaged separately.

3. The machine is tied up with shrinkable PE film in one around .

4. The machine corners are protected by foam and fixed with protective film.

5. Wrap the machine with pearl cotton .

6. Finally wrap it with a gown for reinforcement and tightening.

1. We will prepare a Iron base to ensure the stability of the machine and the convenience of loading and unloading containers;

2. We will disassemble the laser source , and the laser source will be separately packed in a wooden box. At the same time, auxiliary accessories such as chillers and fans are packaged separately.

3. The machine is tied up with shrinkable PE film in one around .

4. The machine corners are protected by foam and fixed with protective film.

5. Wrap the machine with pearl cotton .

6. Finally wrap it with a gown for reinforcement and tightening.

Due to the large size of the fiber laser cutting machine, most customers will choose sea and rail transportation.

A 20ft container can only be loaded with 1 set fiber laser cutting machine;

A 40ft high container can hold 5 sets fiber laser cutting machines;

If you have a professional technical team, in order to save freight, we can choose to disassemble the gantry structure to reduce the space, so as to achieve the purpose of loading more quantities of fiber laser cutting machine .

A 20ft container can only be loaded with 1 set fiber laser cutting machine;

A 40ft high container can hold 5 sets fiber laser cutting machines;

If you have a professional technical team, in order to save freight, we can choose to disassemble the gantry structure to reduce the space, so as to achieve the purpose of loading more quantities of fiber laser cutting machine .

Practice has proved that by disassembling the gantry structure, a 40ft high container , we can load up to 9 sets fiber laser cutting machines .

Hot Searches