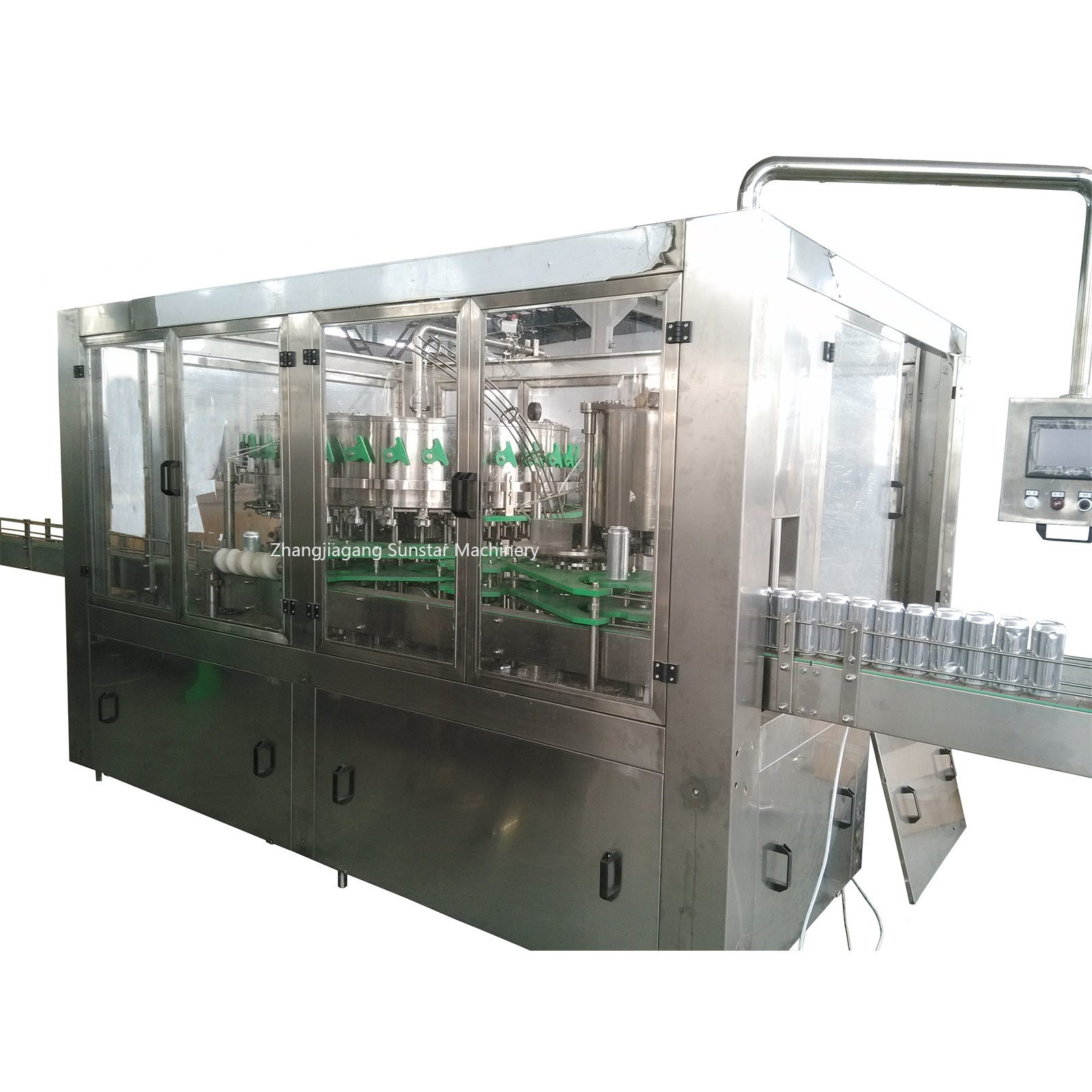

Whole machine

The structure of the

can filler

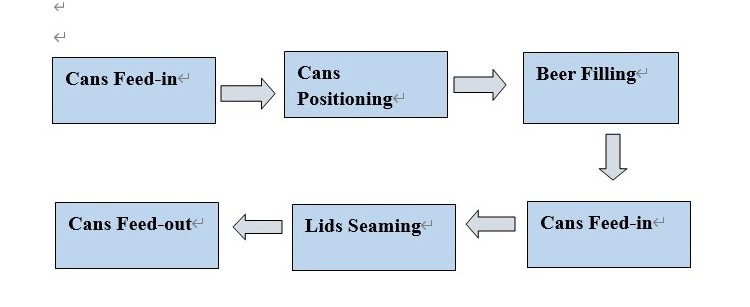

mainly consists of a base, driving device, a temporary storage tank for beer, a lifting device, a filling mechanism and so on. Can filler adopt a rotary structure and can be equipped with up to 200 filling valves. Empty cans are fed into the filling machine through a transmission belt, separated by a screw can dividing device at certain intervals, and then transferred to a lifting tray through an can input star wheel. Finally, the cans are positioned below the filler. Filling completed, cans lowered onto the tray before being sent out of the machine.

Can seamer

is mono-blocked, continuous motion rotary seaming system. Not only does this mean that every can is seamed in the same amount of time after being filled, unlike inline fillers and seamers, but this also deliver more consistent seaming performance, smoother can transfer, better speed control and reduced O2-Oxygen pick up.