Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2022

-

Application:

-

Cold rolling

-

After Warranty Service:

-

1 Year

-

Steel strip material:

-

Q235A or Q345A

-

Steel strip thickness:

-

2 mm -6mm

-

Steel strip width:

-

30 mm-120mm

-

Spiral blade inner diameter:

-

50-120 mm

-

Roller working speed:

-

6 turns/min

-

Motor power:

-

37KW

-

Machine size:

-

8000x5500x2700mm

-

Product name:

-

Sectional Spiral Blade Screw Flight Hydraulic Cold Rolling Machine

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

bobo

-

Weight (KG):

-

9000

-

Marketing Type:

-

New Product 2022

-

Application:

-

Cold rolling

-

After Warranty Service:

-

1 Year

-

Steel strip material:

-

Q235A or Q345A

-

Steel strip thickness:

-

2 mm -6mm

-

Steel strip width:

-

30 mm-120mm

-

Spiral blade inner diameter:

-

50-120 mm

-

Roller working speed:

-

6 turns/min

-

Motor power:

-

37KW

-

Machine size:

-

8000x5500x2700mm

-

Product name:

-

Sectional Spiral Blade Screw Flight Hydraulic Cold Rolling Machine

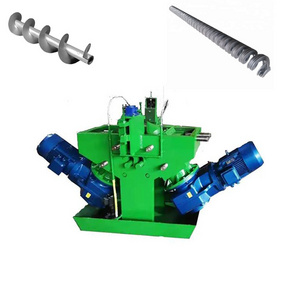

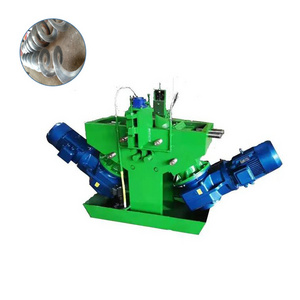

Sectional Helical Spiral Auger Blade Screw Flight Hydraulic Press

Cold Rolling Forming Qualified Machine

★ Description

The cold-rolled spiral blade machine has changed the traditional method of making spiral blades in the past. The spiral blade forming machine has promoted the development of industrialization. The spiral blade is mainly used in conveying machinery, stirring machinery, and pile drilling machinery, pharmaceutical machinery, environmental protection machinery industry. According to the characteristics of different conveying materials, screw conveyors can be divided into shaftless screw conveying and shafted screw conveying. The cold-rolled spiral blade machine produced by our company can process various specifications of carbon steel spiral blades and stainless steel spiral blades through the conical roller extrusion method. precise.

★ Details

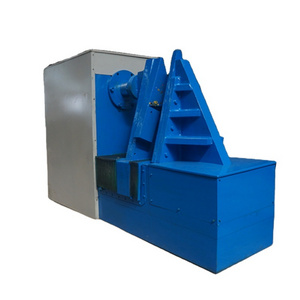

✔ Steel body

It is welded by high-quality thickened steel plate, which is durable and long-lasting, with high dimensional accuracy and surface hardness.

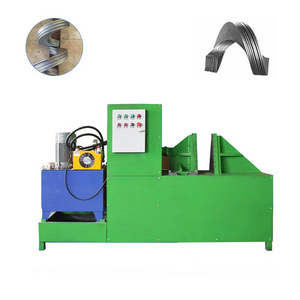

✔ Running smoothly

The finished product has a high reasonable rate, a rounded arc, and easy welding.

✔ Steel body

It is welded by high-quality thickened steel plate, which is durable and long-lasting, with high dimensional accuracy and surface hardness.

✔ Running smoothly

The finished product has a high reasonable rate, a rounded arc, and easy welding.

✔ Processing a variety of specifications

The operation is simple, the structure is reasonable, the machining accuracy is high, and various specifications can be processed.

✔ Superior performance

The spiral blade has the advantages of smooth surface, no welding seam, high hardness, good wear resistance, smooth conveying and reducing material damage rate.

★ Processing Effect Display

★ Parameter Main Data

|

NO.

|

Item

|

Parameter

|

|

1

|

Max. OD

|

1800mm

|

|

2

|

Min. ID

|

20mm

|

|

3

|

Thickness

|

2-30mm

|

|

4

|

Pitch Range

|

100-2000mm

|

|

5

|

Max. Width (OD-ID)/2

|

1000mm

|

|

6

|

Power(380V/3Ph/50Hz)

|

5.5kw

|

|

7

|

Machine Size

(L*W*H)

|

2900*950*1200mm

|

|

8

|

Machine weight

|

3000kg

|

Packaging:

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

Hot Searches