- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

4

-

Weight (KG):

-

500

-

Color:

-

Customer Choice

-

Advantage:

-

High Separator Rate 98-99%

-

Useage:

-

Separate copper and wire

-

Application:

-

waste wires

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

New product 2023

-

Brand Name:

-

Fante

-

Power (kW):

-

4

-

Weight (KG):

-

500

-

Color:

-

Customer Choice

-

Advantage:

-

High Separator Rate 98-99%

-

Useage:

-

Separate copper and wire

-

Application:

-

waste wires

▶︎Copper wire granulator is a specialized equipment used for processing scrap copper wire, playing a crucial role in the recycling and reutilization of copper scrap. With advanced technology and innovative design, the copper wire granulator efficiently separates, crushes, and refines the scrap copper wire to extract high-purity copper granules.

|

Model

|

FTG-02

|

FTG-03

|

FTG-04A

|

FTG-04B

|

FTG-06

|

||||

|

Power

|

4.33kw

|

5.33kw

|

18.5kw

|

16.47kw

|

42kw

|

||||

|

Output

|

30-50kg

|

60-80kg

|

150-200

|

200-300

|

|

||||

|

Applicable Scope

|

≤20mm

|

|

≤30mm

|

|

|

||||

|

Weight

|

450kg

|

500kg

|

1700

|

1000

|

3000

|

||||

|

Application

|

Separate Copper and Sheath Of Cable Wire

|

|

|

|

|

||||

|

Overall Dimension

|

1150*600*1700

|

|

2000*1800*2000

|

1500*1500*2000

|

3800*2000*2300

|

||||

▶︎

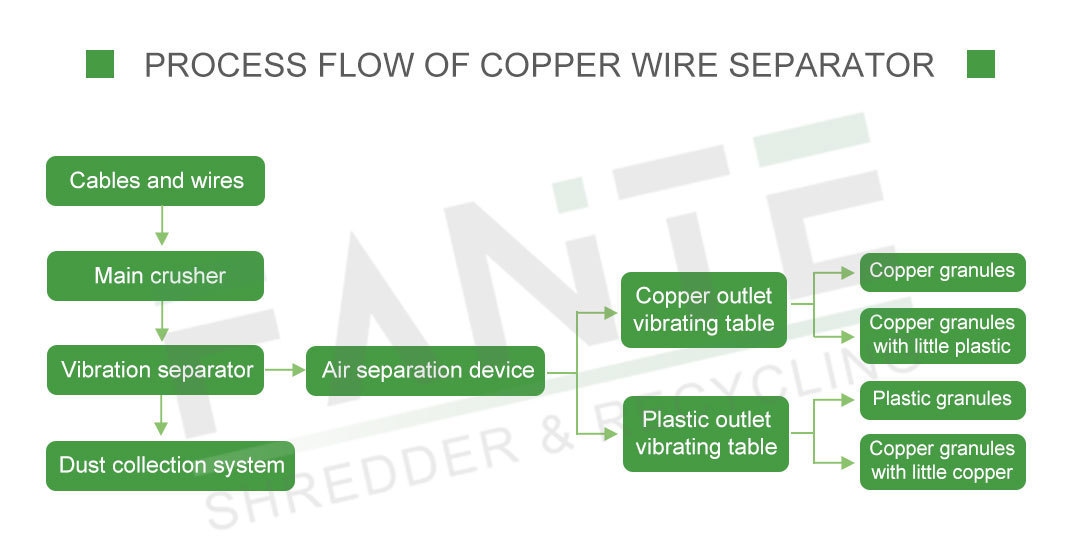

Put the cables into the feed hole, the main crusher will crush cables into mixed granules.

▶︎

The separation device separates copper and plastic from the crushed mixed particles, and the dust collection system collects dust at the same time.

▶︎

Then the vibrating table separates the pure copper for the second time.

According to the different specific gravity of copper and plastic, under the action of an eccentric shaft, combined with a fan, the copper and plastic particles are separated and discharged at different discharge ports for classification.

➤02

Air Blower

The wind generated by the fan blows down copper and plastic through the separation net. Under the action of the eccentric shaft, heavier copper is discharged at the front port, while lighter plastic is blown up by the wind and discharged at the rear port.

The dust inside the crusher and the dust generated in the separation bed are collected into the dust removal bag by the front and rear dust removal fans, achieving the purpose of cleaning the dust.

Control switch, easy to operate, with overload protection to protect the normal operation of the machine.

Electrical components adopt well-known brands such as Schneider and Delixi

▶︎Copper wire granulator is a specialized equipment used for processing scrap copper wire, playing a crucial role in the recycling and reutilization of copper scrap. With advanced technology and innovative design, the copper wire granulator efficiently separates, crushes, and refines the scrap copper wire to extract high-purity copper granules.

|

Model

|

FTG-02

|

FTG-03

|

FTG-04A

|

FTG-04B

|

FTG-06

|

||||

|

Power

|

4.33kw

|

5.33kw

|

18.5kw

|

16.47kw

|

42kw

|

||||

|

Output

|

30-50kg

|

60-80kg

|

150-200

|

200-300

|

|

||||

|

Applicable Scope

|

≤20mm

|

|

≤30mm

|

|

|

||||

|

Weight

|

450kg

|

500kg

|

1700

|

1000

|

3000

|

||||

|

Application

|

Separate Copper and Sheath Of Cable Wire

|

|

|

|

|

||||

|

Overall Dimension

|

1150*600*1700

|

|

2000*1800*2000

|

1500*1500*2000

|

3800*2000*2300

|

||||

▶︎

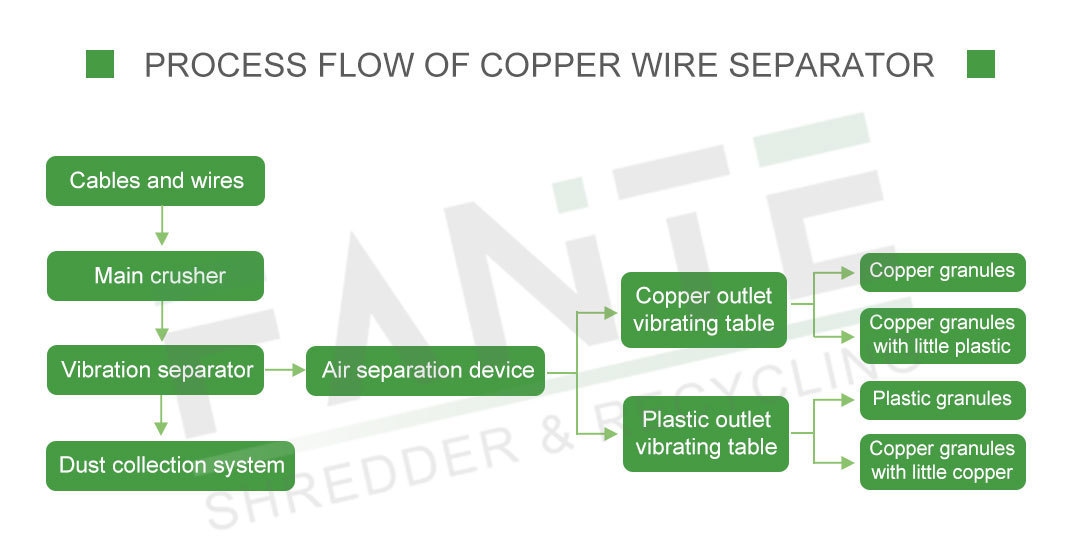

Put the cables into the feed hole, the main crusher will crush cables into mixed granules.

▶︎

The separation device separates copper and plastic from the crushed mixed particles, and the dust collection system collects dust at the same time.

▶︎

Then the vibrating table separates the pure copper for the second time.

According to the different specific gravity of copper and plastic, under the action of an eccentric shaft, combined with a fan, the copper and plastic particles are separated and discharged at different discharge ports for classification.

➤02

Air Blower

The wind generated by the fan blows down copper and plastic through the separation net. Under the action of the eccentric shaft, heavier copper is discharged at the front port, while lighter plastic is blown up by the wind and discharged at the rear port.

The dust inside the crusher and the dust generated in the separation bed are collected into the dust removal bag by the front and rear dust removal fans, achieving the purpose of cleaning the dust.

Control switch, easy to operate, with overload protection to protect the normal operation of the machine.

Electrical components adopt well-known brands such as Schneider and Delixi

Hot Searches