- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SINOROADER

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

9760 KG

-

Marketing Type:

-

Hot Product

-

Product Model:

-

PF-1315

-

Rotor Diameter:

-

1000mm

-

Rotor Length:

-

1000mm

-

,Max Feeding Size:

-

500mm

-

Power:

-

200kw

-

Capacity:

-

100-280t/h

-

Weight(exclude motor):

-

9760kg

-

Overall Dimension:

-

1840*2140*2070mm

-

Certification:

-

ISO CE

-

Advantage:

-

High Efficiency Low Energy

Quick Details

-

Application:

-

quarry, mining, metallurgy

-

Capacity(t/h):

-

55-250T/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SINOROADER

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

9760 KG

-

Marketing Type:

-

Hot Product

-

Product Model:

-

PF-1315

-

Rotor Diameter:

-

1000mm

-

Rotor Length:

-

1000mm

-

,Max Feeding Size:

-

500mm

-

Power:

-

200kw

-

Capacity:

-

100-280t/h

-

Weight(exclude motor):

-

9760kg

-

Overall Dimension:

-

1840*2140*2070mm

-

Certification:

-

ISO CE

-

Advantage:

-

High Efficiency Low Energy

Product Overview

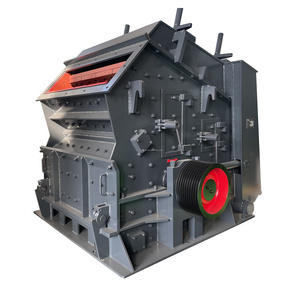

Impact Crusher

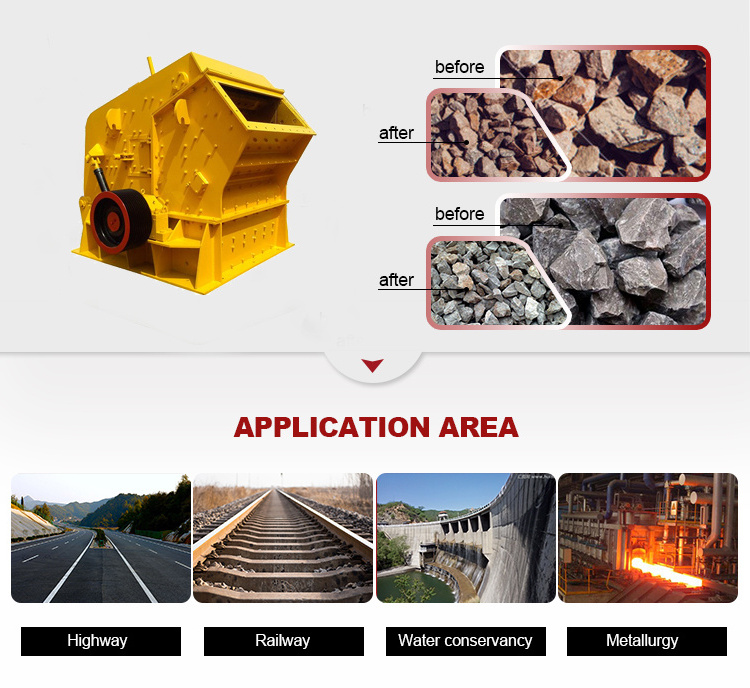

Impact Crusher can crush the large, medium and small size materials (granite, limestone, concrete, etc).With max feed size less than 500mm and compression strength less than 350Mpa.

It is widely used in metallurgy, mine, cement, chemical engineering, fire resistant materials, ceramics and other industrial sectors, as well as in the expressway construction, water conservancy project, building crushed stone, and machine-made sand process fields, etc.

Impact crusher is commonly used secondary crushing equipment or tertiary crushing equipment for medium or fine crushing, which

is suitable for medium hardness and soft materials (limestone, coal gangue, etc.), using impact to crush materials, repeated impact between the blow bar and the impact plate for crushing, the new structure design. The machine has strong rigidity, and the rotor has a large Moment of inertia. The finished product is cubic, without tension and cracks.

Impact crusher is a kind of stone crusher using impact energy. After turn on,the motor drives the rotor rotate at a high speed .When the material get into the blow bar working area,they will be stroke by the blow bar and thrown to the impact devices around the rotor.The material will come out from the discharge hole until they are crushed to the required size. The clearance between the impact rack and the rotor can adjust the size and shape of the end product.

Product Structure

|

Model

|

Specification (mm)

|

Feed opening (mm)

|

Max. feeding size (mm)

|

Capacity (tph)

|

Power (kw)

|

|

PF-1007

|

Φ1000×700

|

400x730

|

300

|

30-70

|

37-45

|

|

PF-1010

|

Φ1000×1050

|

400x1080

|

350

|

50-90

|

45-55

|

|

PF-1210

|

Φ1250×1050

|

400x1080

|

350

|

70-130

|

110

|

|

PF-1214

|

Φ1250×1400

|

400x1430

|

350

|

80-180

|

132

|

|

PF-1315

|

Φ1320×1500

|

860x1520

|

500

|

100-280

|

200

|

|

PF-1320

|

Φ1300×2000

|

993x2000

|

500

|

140-380

|

250

|

|

PF-1520

|

Φ1500×2000

|

830x2040

|

700

|

200-550

|

315-400

|

|

PF-1820

|

Φ1800×2000

|

1260x2040

|

800

|

300-800

|

630-710

|

Why Choose Us

Hot Searches