- Product Details

- {{item.text}}

Quick Details

-

Power:

-

270-500kw

-

Dimension(L*W*H):

-

portable asphalt plant model

-

Weight:

-

kg

-

Product name:

-

China portable asphalt plant 80-160tph mobile batch mixing machinery

-

Type:

-

Mobile batch asphalt mixing plant

-

Capacity:

-

80-160t/h

-

Mixer capacity:

-

1000-2000kg/batch

-

Weighing system:

-

METTLER TOLEDO,USA

-

Pneumatic system:

-

GERMAN

-

Control system:

-

SIEMENS,GERMAN

-

Burning system:

-

EBICO,ITALY

-

Operation:

-

Auto & Manual

-

Color:

-

Client's Customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOOMLINE

-

Voltage:

-

220V/380V-50Hz

-

Power:

-

270-500kw

-

Dimension(L*W*H):

-

portable asphalt plant model

-

Weight:

-

kg

-

Product name:

-

China portable asphalt plant 80-160tph mobile batch mixing machinery

-

Type:

-

Mobile batch asphalt mixing plant

-

Capacity:

-

80-160t/h

-

Mixer capacity:

-

1000-2000kg/batch

-

Weighing system:

-

METTLER TOLEDO,USA

-

Pneumatic system:

-

GERMAN

-

Control system:

-

SIEMENS,GERMAN

-

Burning system:

-

EBICO,ITALY

-

Operation:

-

Auto & Manual

-

Color:

-

Client's Customized

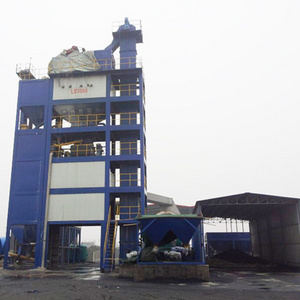

China portable asphalt plant 80-160tph mobile batch mixing machinery for sale

ZAP-M series portable asphalt plant batch mixing machinery mainly used in the road construction of national road,main or middle road,city road,airport and bridge, transport and install conveniently.

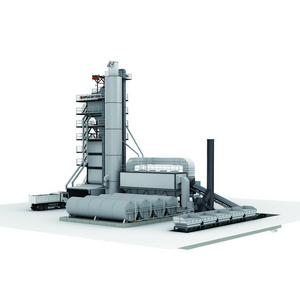

Mobility, efficiency, easily transportable mobile/portable batch asphalt mixing plant

ZAP-M models portable asphalt plant batch mixing machinery are available from 80TPH to 160TPH

The transport status of portable asphalt plant batch mixing machinery mixer t ower

Advantages of ZAP-M series portable asphalt plant batch mixing machinery

1.Modular design, convenient and fast to move and install.

2.Screening, hot storage, weighting are on one folding frame, can realize main tower “one truck to trail”.

3.Few transport vehicle, installation foundation need no special handle.

4.Compact design, cover very small area.

5.Accurate screening, weighting, batch mix can guarantee high quality.

6.International classic quality control system, has long distance fault detect and maintain function.

Cold Aggregate Feeding System

- The belt feeder use frequency conversion speed control, speed adjust rang is wide, high working efficiency.

- Every hopper discharge gate have material shortage alarming device, if material shortage or material arching, it will alarm automatically.

- On the sand bin, there is vibrator, so it can guarantee normal working.

- There is isolation screen on top of cold bin, so can avoid large material input.

- The conveyor belt use circular belt without joint, steady running and long performance life.

- At the input port of feeding belt conveyor, there is one simple screen can avoid big material input which can enhance hot efficiency and make sure the drying drum, hot aggregate elevator and vibration screen work reliability.

- Landing legs with support bases to ensure adequate stability.

Drying System

- The blade geometry of the dryer has been optimized to deliver an exceptionally efficient drying and heating process with reduced energy consumption,improve heating efficiency 30% than conventional design; Because of High heating efficiency, drum surface temperature is relatively low, so the cooling time after operation is considerably shorted.

- Fully insulated and clad aggregate dryer. Drive by electric motors and gear unit through polymer friction drive support rollers.

- Adopt famous brand HONEYWELL temperature intelligent control system.

- Adopt high combustion efficiency Italian brand burner, make sure low exhaust gas emission (like CO2,low No1 & No2, So2).

- Diesel, heavy oil, gas, coal or multi-fuel burners.

- Landing legs with support bases to ensure adequate stability.

- Integrated highly efficient burner on one mobile chassis.

Mixing Tower

- Integrated vibrating screen and hot storage and weighing and mixer in one mobile chassis, easily transportable and installation.

- Improved vibration and amplitude to optimize impact on the available screen. the best combination of vibrating direction & screen box dip angle, ensure ratio and screening efficiency.

- Adopt famous brand METTLER TELEDO weighing sensor, make sure accurate weighing, in order to make sure the asphalt mixture quality.

- Mixer are designed by 3D mixing design, with long arms, shortened shaft diameter and a bi-directional mixing blades array. the discharging process has been completely redesigned, the discharge time is minimal. the distance between blades and bottom of the mixer is also restrained to the optimal minimum.

- Bitumen is sprayed from multi-points evenly over aggregate by one pressurized bitumen pump to achieve full coverage and high mixing efficiency.

- Landing legs with support bases to ensure adequate stability.

Dust Collecting System

- Gravity primary dust collector collecting and recycling bigger fine, saving consumption.

- Bag house secondary dust filter control emission be lower than 20mg/Nm3, eco-friendly.

- Adopt USA Dopont NOMEX filter bags, high temperature resistance and long service life, and the filter bags ban be replaced easily and quickly with no need for special tools.

- Intelligent temperature and control system, when the dust air temperature is higher than set data, cold air valve will be opened automatically for cooling, avoid the filter bags are damaged by high temperature.

- Adopt high voltage pulse cleaning technology, contributing to a lower bag wearing, longer lifespan and better dust removal performance.

- Mobile chassis as optional according to project solution.

Control system

- Adopt Germany SIEMENS electrical element, working stably even in harsh working environment.

- Adopt Japan ORMON PLC and touch screen, have high data processing capacity, with automatic data sheet control, various operation data can be saved real-times.

- All system power switches can be controlled via control panel,easy operation and control.

- Multi-language compatibility, display language can be selected according to the customer’s preference.

- Control cabinet adopt IP55 safety protection class which can match highest industrial standard in whole global.

- Containerized control room, with heat insulation and sound insulation layer.

- Global remote automatic detection function.

- Mobile chassis as optional according to project solution

Technical parameters of ZAP-M series 80-160tph portable asphalt plant batch mixing machinery

| Items | ZAP-M80 | ZAP-M100 | ZAP-M120 | ZAP-M160 | ||

| Plant Capacity | 80t/h | 100t/h | 120t/h | 160t/h | ||

| Cold Aggregate Feeding System | ||||||

| Hopper capacity | 4 x 6.5m3 | 4 x 6.5m3 | 4 x 6.5m3 | 5 x8m3 | ||

| Belt capacity | 100t/h | 120t/h | 140t/h | 180t/h | ||

| Drying System | ||||||

| Drying drum size | 1500x6600mm | 1500x6600mm | 1800x8000mm | 1900x9000mm | ||

| Drying capacity | 80-100t/h | 100-120t/h | 120-140t/h | 160-180t/h | ||

| Burner (oil) | 60-600kg/h | 100-1000kg/h | 100-1000kg/h | 140-1400kg/h | ||

| Fuel consumption (oil) | 6.5-7kg/t | 6.5-7kg/t | 6.5-7kg/t | 6.5-7kg/t | ||

| Mixing Tower | ||||||

| Screen | 4 layer | 4 layer | 4 layer | 4/5 layer | ||

| Aggregate weighing | 3x1000kg | 3x1500kg | 3x1500kg | 3x2000kg | ||

| Bitumen weighing | 3x100kg | 3x200kg | 3x200kg | 3x200kg | ||

| Filler weighing | 3x100kg | 3x200kg | 3x200kg | 3x200kg | ||

| Mixer capacity | 1000kg | 1300kg | 1500kg | 2000kg | ||

| Mixing cycle | 45s | 45s | 45s | 45s | ||

| Dust Collecting System | ||||||

| Bag house filtering | 380m2 | 400m2 | 500m2 | 550m2 | ||

| Exhaust Fan power | 45kw | 55kw | 2x45kw | 2x55kw | ||

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | ||

| Finished Asphalt Silo (Optional) | 30 ton | 30 ton | 30 ton | 60 ton | ||

| Total Power | -270kw | -300kw | -390kw | -500kw | ||

ZAP-S series stationary batch asphalt mixing plant

ZAP-C(M) series continuous asphalt drum mix plant