- Product Details

- {{item.text}}

Quick Details

-

Filter Rating:

-

99%

-

Thickness:

-

0.1mm to 10mm

-

Length:

-

Customize Length

-

Width:

-

Customize Size

-

Product name:

-

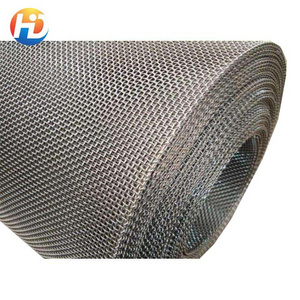

Stainless Steel Wedge Wire Filter Mesh

-

Application:

-

Chemical Industry

-

Shape:

-

Cylindrical

-

Color:

-

Silver

-

Feature:

-

Corrosion Resistance

-

Weave style:

-

Dutch Weave

-

Wire Diameter:

-

0.02mm to 1.5mm

Quick Details

-

Weight (KG):

-

0.5

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YOUJIU

-

Filter Rating:

-

99%

-

Thickness:

-

0.1mm to 10mm

-

Length:

-

Customize Length

-

Width:

-

Customize Size

-

Product name:

-

Stainless Steel Wedge Wire Filter Mesh

-

Application:

-

Chemical Industry

-

Shape:

-

Cylindrical

-

Color:

-

Silver

-

Feature:

-

Corrosion Resistance

-

Weave style:

-

Dutch Weave

-

Wire Diameter:

-

0.02mm to 1.5mm

Product Description

Sintered wire mesh is made from multiple layers of woven wire mesh panels together using a sintering process. This process combines heat and pressure to permanently bond multi-layers of mesh together. The same physical process used to fuse individual wires together within a layer of wire mesh is also be used to fuse adjacent layers of mesh together. This creates a unique material offering excellent mechanical properties. It is an ideal material for purification and filtration. It may be from 5, 6 or 7 layers of wire mesh

Features:

Apertures of every layers are interlaced to build an ideal and uniform filter structure, which determines its advantages much better than regular wire mesh, such as high strength, good rigidity, fixing size of aperture. The aperture size,permeability and strength of wire mesh are composable and devisable, meshes that owns this structure can present excellentperformance of filter precision, filter resistance, machinability, as a result the comprehensive performance is thoroughly better than other filter medias.

|

Micron size

|

0.2μm - 300 microns

|

|

Filter rating

|

1-2460um

|

|

Material

|

SUS 304 SUS 304L SUS 316 SUS 316L other alloys available as required

|

|

Layer

|

1-5 or as required

|

|

Technique

|

Weave and Sintering

|

|

The thickness size

|

0.2 - 10 mm or as required

|

|

Shape

|

Rectangle, square, round, oval, circular, cap, waist, and abnormity.

|

|

Sample

|

Available

|

|

Feature

|

High temperature and corrosion resistance

|

|

Application

|

Industry Filter Sieve

|

Product Applications

Sintered Filter Mesh Applications

All of the benefits listed above and several others make sintered wire cloth an excellent choice for a wide range of applications,

including:

* Oil & Gas: The oil and gas industry can use diffusion bonded wire cloth for efficient sand control over numerous types of

formation sands, as well as for multiple gravel-pack applications.

* Fluidization: Use sintered wire cloth for fluidizing bulk powders and solids under the most challenging conditions, such as extreme-temperature and high-corrosion environments.

* Power generation: Diffusion bonded wire cloth can maximize the performance of power generation filtration systems for

applications such as reactor water cleanup and fuel pool cleanup. It can also help to lower the operating costs in condensate filter and polishing systems.

* General industry: General industrial applications of sintered wire cloth include catalyst recovery, steam filtration, polymer

filtration, demineralizing and many others.

including:

* Oil & Gas: The oil and gas industry can use diffusion bonded wire cloth for efficient sand control over numerous types of

formation sands, as well as for multiple gravel-pack applications.

* Fluidization: Use sintered wire cloth for fluidizing bulk powders and solids under the most challenging conditions, such as extreme-temperature and high-corrosion environments.

* Power generation: Diffusion bonded wire cloth can maximize the performance of power generation filtration systems for

applications such as reactor water cleanup and fuel pool cleanup. It can also help to lower the operating costs in condensate filter and polishing systems.

* General industry: General industrial applications of sintered wire cloth include catalyst recovery, steam filtration, polymer

filtration, demineralizing and many others.

Recommend Products

Packing & Delivery

Large quantity deliveried by sea shipping or air transport.

Small quantity deliveried by courier such as EMS,DHL,UPS,FEDEX.

Hot Searches