- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

9100*1100*1750mm

-

Power (kW):

-

29

-

Weight (KG):

-

3500 kg

-

Panel Feed Speed(m/min):

-

23m/min

-

Edge Thickness:

-

0.4-3mm

-

Panel thickness:

-

10-60mm

-

Panel length:

-

>=150mm

-

Panel width:

-

>=60 mm

-

Working Pressure:

-

0.6Mpa

-

Feed Speed:

-

15-23m/min

-

Motor Power:

-

29KW

-

Electrical Lift:

-

yes

-

Overall dimensions:

-

9100*1100*1750mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Holyiso

-

Voltage:

-

380 V(220V,400V,415V,440V etc)

-

Dimension(L*W*H):

-

9100*1100*1750mm

-

Power (kW):

-

29

-

Weight (KG):

-

3500 kg

-

Panel Feed Speed(m/min):

-

23m/min

-

Edge Thickness:

-

0.4-3mm

-

Panel thickness:

-

10-60mm

-

Panel length:

-

>=150mm

-

Panel width:

-

>=60 mm

-

Working Pressure:

-

0.6Mpa

-

Feed Speed:

-

15-23m/min

-

Motor Power:

-

29KW

-

Electrical Lift:

-

yes

-

Overall dimensions:

-

9100*1100*1750mm

Products Description

Advantage:

1.Adopt domestic famous motor and high quality electrical components.

1.Adopt domestic famous motor and high quality electrical components.

2.The machine can be customized. Auto cleaning, high precision, high efficiency.

3.Aluminum alloy beam is a relatively advanced method,precisione and straightness are far superior to cast iron. 4.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

3.Aluminum alloy beam is a relatively advanced method,precisione and straightness are far superior to cast iron. 4.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

Application:

The machine is suitable for the following boards: MDF, block board, solid wood board, particleboard, polymer door plates, plywood, pvc board, etc. Straight line edging and trimming.

The machine is suitable for the following boards: MDF, block board, solid wood board, particleboard, polymer door plates, plywood, pvc board, etc. Straight line edging and trimming.

|

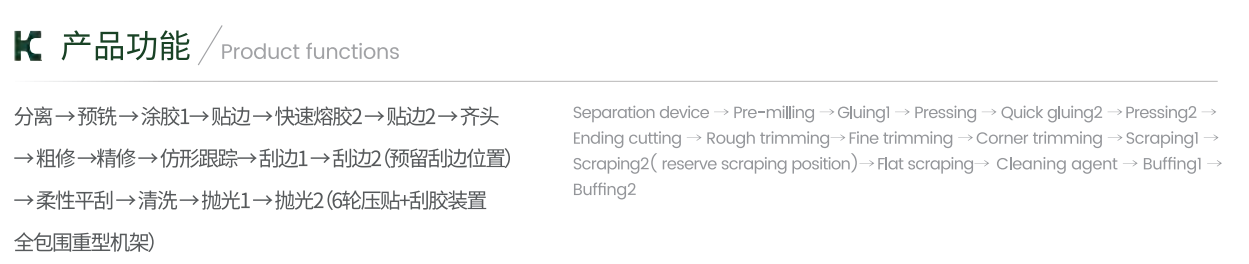

Model

|

KIE-465J

|

KIE-668JSG

|

|

Function

|

Pre-milling,

Gluing,

End trimming,

Rough trimming,

Fine trimming, Scraping, Buffing |

Separation device- > Pre-milling > Gluingl→Pressing > Quick gluing2→Pressing2- >Ending cutting→Rough trimming > Fine trimming-→

Corner trimming- > Scraping1-Scraping2( reserve scraping position)- > Flat scraping- > Cleaning agent→Buffing1-→Buffing2 |

|

Edge thickness

|

0.4-3mm

|

0.4-3mm

|

|

Panel thickness

|

10-60mm

|

9-60mm

|

|

Panel length

|

>=150mm

|

>=150mm

|

|

Panel width

|

>=60mm

|

>=60mm

|

|

Working Pressure

|

0.6Mpa

|

0.6Mpa

|

|

Feed Speed

|

12-20m/min

|

15-23m/min

|

|

Electrical Lift

|

yes

|

yes

|

|

Motor Power

|

13.9kw

|

29KW

|

|

Overall dimensions

|

6200x900x1800mm

|

9100x1100x1750mm

|

|

Weight

|

2200kg

|

3500kg

|

Details Images

Pre-milling

Solve defects such as burrs and edge chipping of the board to achieve a better edge banding effect.

Gluing

Adopt special structure,make plate and edge sealing strip glue evenly, to ensure more firm ashesion.

End Trimming

Stable and reliable operation, fast cutting edge banding , to ensure a smooth cutting surface.

Rough Trimming/Fine Trimming

01.Rough trimming:

The rough trimming knife is flat. Used to remove excess edge banding.

02. Fine trimming: Fine trimming knife is R type knife, which is used to remove the excess edge banding above and below the plate,so that the upper and lower parts of the board are smooth.

02. Fine trimming: Fine trimming knife is R type knife, which is used to remove the excess edge banding above and below the plate,so that the upper and lower parts of the board are smooth.

Corner Trimming

The upper and lower four corners are processed to be rounded, and the end surface of the board is smooth and beautiful.

Scraping

Used to eliminate ripple marks caused by trimming process, make the upper and lower parts of the plate more smooth and tidy.

Cleaning Device

After spraying cleaning agent,polishing wheel is easier to clean excess glue, improve the surface finish of the plate.

Buffing

Clean the board with cotton buffing wheel to make the edge banding end face smoother.

Features :

1.The glue mechanism adopts a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

2.End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

3.This edge bander is ideal for building an automatic production line. Stability and controlled ability are the most important,factors for an equipment to be part of production line.

1.The glue mechanism adopts a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

2.End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

3.This edge bander is ideal for building an automatic production line. Stability and controlled ability are the most important,factors for an equipment to be part of production line.

■ The machine can be used for whole house customization, panel furniture, kitchen dining room, oddice cabinet table,etc.

Product packaging

We will ensure that your machine is clean before packaging.

We will add elastic film to the whole machine and spare parts to provide exquisite protection.

We will produce export standard sturdy wooden box packaging according to your requirements.

We will add elastic film to the whole machine and spare parts to provide exquisite protection.

We will produce export standard sturdy wooden box packaging according to your requirements.

Guarantee:

The machine is guaranteed for 12 months .Within 12 months under normal using and maintenance, if the machine has something problem,you will get spare part for free . More than 12 months,you will get the cost price for accessories. You will also get technical support and service all the time.

Technical support:

Technical support by Phone, Email, Wechat, WhatsApp and Skype, 24 hours online.

We provide English version manual and Operational video.

Engineer available to service machinery overseas.

The machine is guaranteed for 12 months .Within 12 months under normal using and maintenance, if the machine has something problem,you will get spare part for free . More than 12 months,you will get the cost price for accessories. You will also get technical support and service all the time.

Technical support:

Technical support by Phone, Email, Wechat, WhatsApp and Skype, 24 hours online.

We provide English version manual and Operational video.

Engineer available to service machinery overseas.

After sales services:

Our machine is installed and tested well before delivery. You can operate the machine immediately after receiving machine.If you don't know how to use the machine, we will offer you free training until you can use machine freely. And If there is still have any question, please contact us by Email, Skype, Wechat, WhatsApp, Phone and Trade Manager online service at any time.

Recommend Products

Hot Searches