- Product Details

- {{item.text}}

Quick Details

-

Productivity:

-

22M³/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Weight:

-

1800 kg

-

Dimension(L*W*H):

-

3400x1200x1600mm

-

Product name:

-

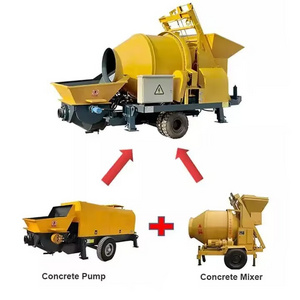

Concrete Pump Mixer

-

Keyword:

-

Concrete Pumping Equipment

-

Application:

-

Construction Engineering

-

Concrete pump type:

-

Reliable Concrete Pumping

-

After Warranty Service:

-

Online Service

-

Engine:

-

Diesel or Electric motor

-

Capacity:

-

15-18/20-25/30-40m3/h

-

Feature:

-

Easy Operation

-

Concrete pump:

-

Small Portable Concrete Pump

-

Certification:

-

CE/ISO9001

Quick Details

-

Power Type:

-

Electric

-

Max. vertical conveying distance:

-

120M

-

Max. horizontal conveying distance:

-

400M

-

Productivity:

-

22M³/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Weight:

-

1800 kg

-

Dimension(L*W*H):

-

3400x1200x1600mm

-

Product name:

-

Concrete Pump Mixer

-

Keyword:

-

Concrete Pumping Equipment

-

Application:

-

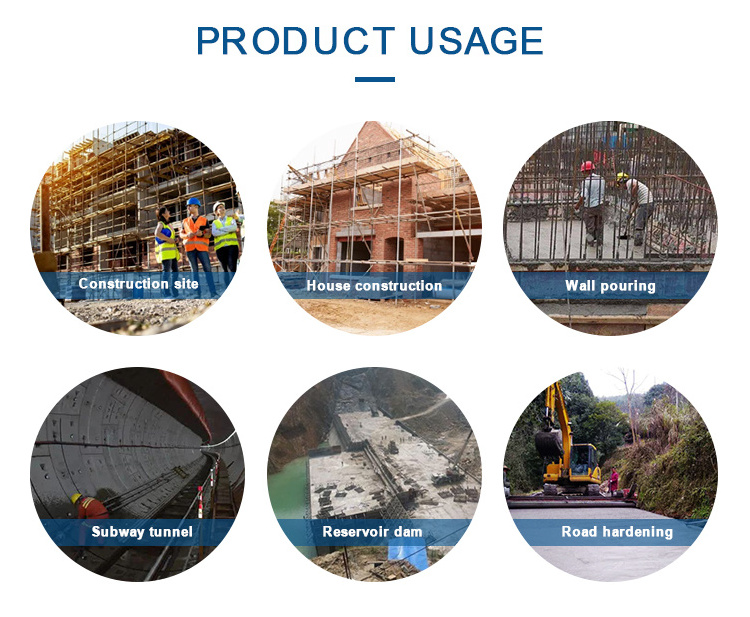

Construction Engineering

-

Concrete pump type:

-

Reliable Concrete Pumping

-

After Warranty Service:

-

Online Service

-

Engine:

-

Diesel or Electric motor

-

Capacity:

-

15-18/20-25/30-40m3/h

-

Feature:

-

Easy Operation

-

Concrete pump:

-

Small Portable Concrete Pump

-

Certification:

-

CE/ISO9001

Product Description

1.The construction site fine stone mortar pump is applied in high-rise building ash mortar and fine stone concrete transportation,secondary structure column grouting, reservoir, hydro power station, port, dock, various pressure grouting, foundation treatment,weak foundation, reinforcement grouting , tunnel Back fill grouting anchor support in subway and mine construction. Other descriptions This product adopts hydraulic feeding, and the double-cylinder reciprocating operation of vibrating net filter can completely transport various mortars, fine stone concrete, etc. in building application. This product has large displacement, high pressure, labor saving, flexible movement, etc. Features, is an ideal mortar conveying equipment. The pump is widely used in indoor construction of urban construction projects (such as infusion of structural columns and invisible columns), anchorage grouting, consolidation grouting and back fill grouting works for underground tunnels of urban subway hydro power stations. It can also be used for grouting of anchor piles during slope and soft rock reinforcement.

1. Using advanced smooth s pipe valve reversing: can meet the transportation of fine stone concrete or commercial fine stoneconcrete, it is not suitable to block the pipe;

2. Spectacle plate and cutting ring: high hardness and wear-resistant alloy material, longer life;

3. High export pressure, it can meet the transportation requirements of high-rise buildings and long-distance construction;

4. The hydraulic oil cooling adopts air cooling system: the cooling effect is good, the use is simple, and it is not easy to

pollute the oil;

5. Adopting stepless manual variable displacement: it can meet the different requirements of many users for the discharge speed;

6. Advanced wireless remote control function: Improve remote control distance, facilitate remote control operation, and makeproducts more humanized;

7. Highly wear-resistant concrete cylinder: guarantees and increases the service life of the concrete pump and reduces

the maintenance cost of the user;

8. The main cylinder of the new process chrome-plated inner hole: thus avoiding the problem of damage to the main cylinder due todirty oil;

9. Highly wear-resistant glasses plate and cutting ring: the use of large-area carbide inserts is the latest technology to improvethe use of glasses;

1. Using advanced smooth s pipe valve reversing: can meet the transportation of fine stone concrete or commercial fine stoneconcrete, it is not suitable to block the pipe;

2. Spectacle plate and cutting ring: high hardness and wear-resistant alloy material, longer life;

3. High export pressure, it can meet the transportation requirements of high-rise buildings and long-distance construction;

4. The hydraulic oil cooling adopts air cooling system: the cooling effect is good, the use is simple, and it is not easy to

pollute the oil;

5. Adopting stepless manual variable displacement: it can meet the different requirements of many users for the discharge speed;

6. Advanced wireless remote control function: Improve remote control distance, facilitate remote control operation, and makeproducts more humanized;

7. Highly wear-resistant concrete cylinder: guarantees and increases the service life of the concrete pump and reduces

the maintenance cost of the user;

8. The main cylinder of the new process chrome-plated inner hole: thus avoiding the problem of damage to the main cylinder due todirty oil;

9. Highly wear-resistant glasses plate and cutting ring: the use of large-area carbide inserts is the latest technology to improvethe use of glasses;

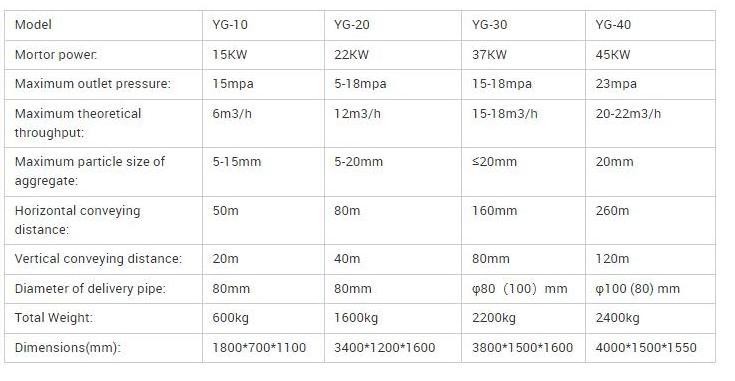

Specification

Product Display

Packing & Delivery

1. Packaging: Packed by standard import & export wooden cases or carton boxes.

2. Shipping: By logistics; by automobile; by train; by shipping; by air etc.

2. Shipping: By logistics; by automobile; by train; by shipping; by air etc.

Hot Searches