- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1330*950*1345mm

-

Power (kW):

-

1.4

-

Weight (KG):

-

200 kg

-

Panel Feed Speed(m/min):

-

15m/min

-

Model:

-

MF108S

-

Product name:

-

Edge banding machine

-

Edge Thickness:

-

0.3-3mm

-

Edge Height:

-

10-48mm

-

Feed speed:

-

0.26m/s

-

Total Power:

-

1.4kw

-

Pressure:

-

3-6MPA

-

After-sales Service:

-

Online

-

Application:

-

Furniture Maker

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

OEM

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

1330*950*1345mm

-

Power (kW):

-

1.4

-

Weight (KG):

-

200 kg

-

Panel Feed Speed(m/min):

-

15m/min

-

Model:

-

MF108S

-

Product name:

-

Edge banding machine

-

Edge Thickness:

-

0.3-3mm

-

Edge Height:

-

10-48mm

-

Feed speed:

-

0.26m/s

-

Total Power:

-

1.4kw

-

Pressure:

-

3-6MPA

-

After-sales Service:

-

Online

-

Application:

-

Furniture Maker

Product Description

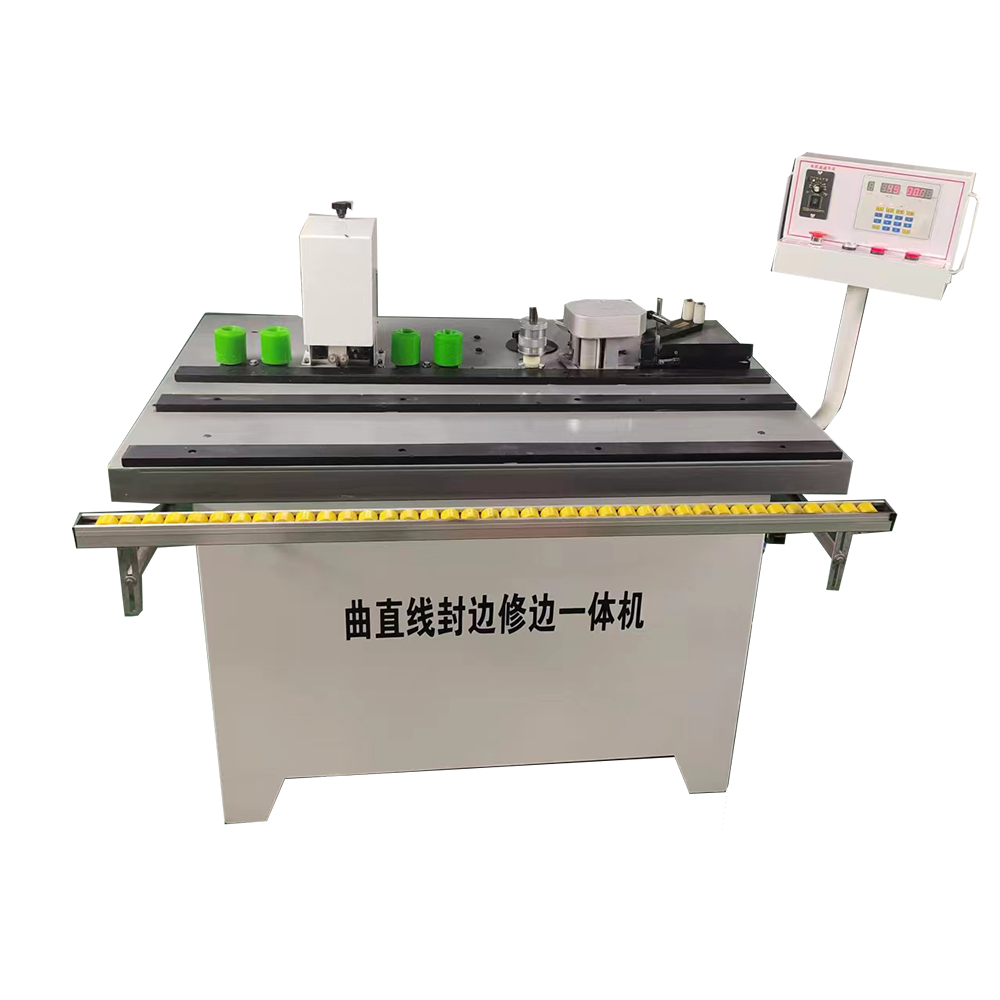

Automatic edge banding machine

MF108S - Straight & curve edge banding machine

Carefully manufactured, stable performance

Suitable for edge banding of most woodworking boards

Widely used in furniture production and decoration industry

Specification

|

Model

|

MF108S

|

|

Voltage

|

220v 50Hz

|

|

Edge Thickness

|

0.3-3mm

|

|

Edge Height

|

10-48mm

|

|

Feed speed

|

0.26m/s

|

|

Power

|

1.4kw

|

|

Weight

|

200kg

|

|

Pressure

|

3-6MPA

|

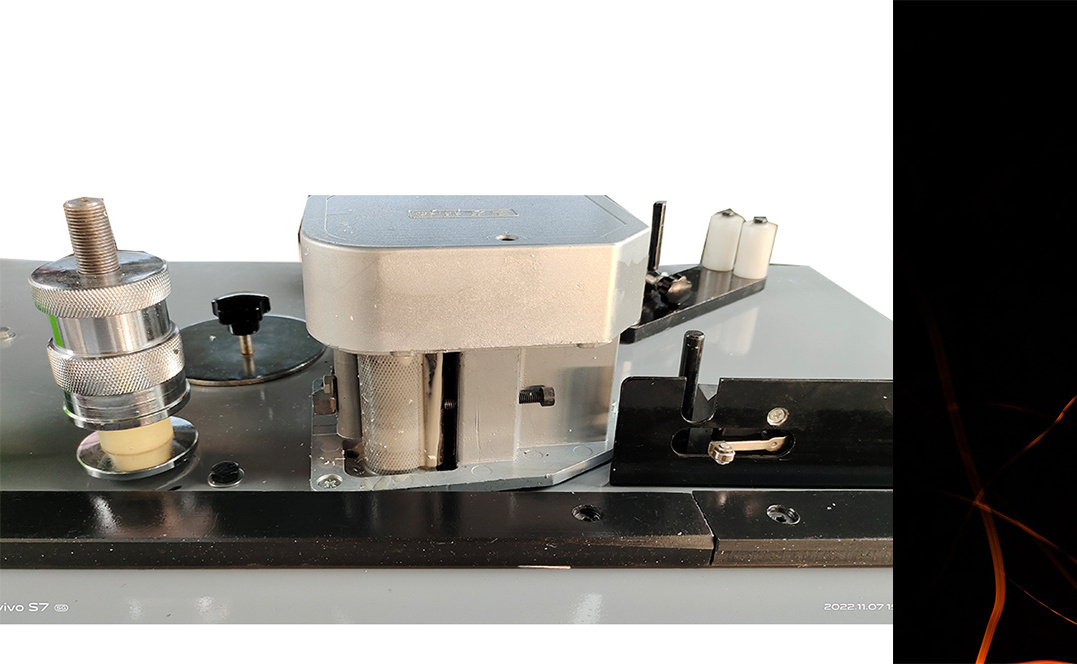

Intelligent temperature control

The temperature controller can be automatically adjusted according to the temperature required by the edge banding and hot melt adhesive

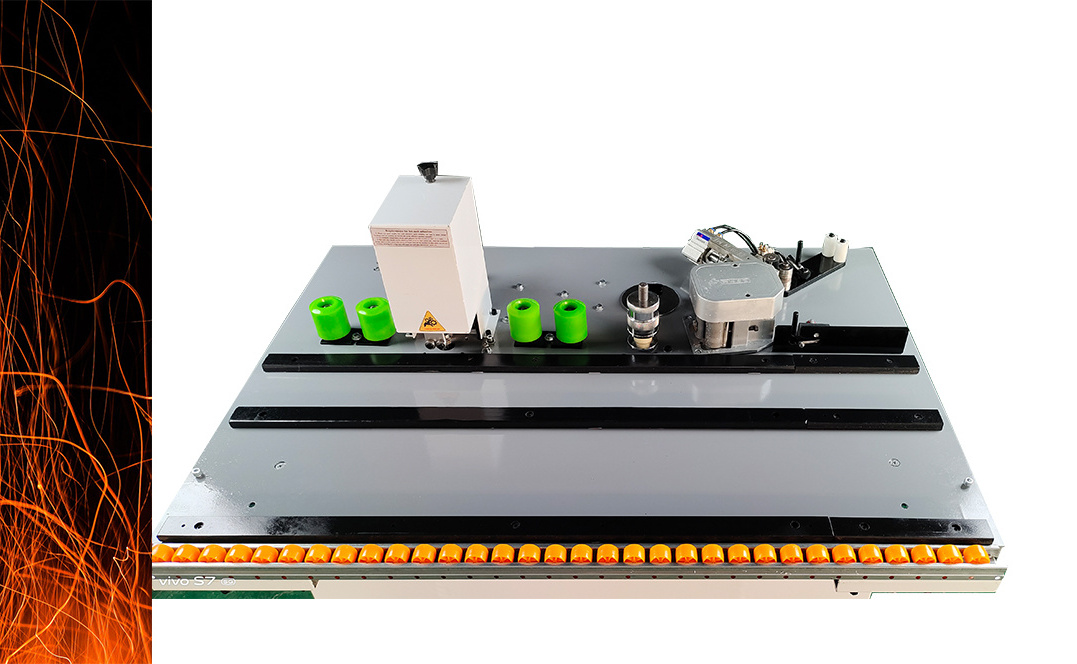

Double-sided gule

Straight line, curve, special shape, and various edge banding can be completed

large operating surface

The operating surface is higher and larger, which is ergonomically designed and more comfortable to use

Quality accessories

The high-quality mechanical original parts of this machine are durable and not easy to damage

Automatic end cutting

This machine is specially designed to automatically end cutting with high quality, cylinder guillotine, strong shearing force, and long service life

Packing & Delivery

About us

Liaoning Felix Technology Co., Ltd

. is located in Shenyang, Liaoning Province. It is a woodworking machinery manufacturer integrating R&D, processing, marketing and application services. At present, the company is mainly engaged in woodworking machinery and panel furniture accessories, providing one-stop professional services for the furniture manufacturing industry.

Since its establishment, the company has insisted on adhering to the idea of learning from others' strengths, pioneering and innovative ideas in the process of rapid development, and has established long-term and stable cooperative relations with the majority of users.

The integrity, strength, and product quality of Liaoning Felix Technology Co., Ltd. have been recognized and trusted by customers through out the whole world.

Diligent and sincere, we look forward to working with you hand in hand to create brilliance together.

After Sales service

Pre-sale service

: Professionals will introduce the product's performance to customers.

Recommend the most satisfactory product of our company to customers according to the effect that customers produce.

In sale service:

The salesman will be prepared to keep in smooth touch with the company's production line according to customers' demands in order to deliver the goods on time.

After-sales service

:Professional after-sale service staff will follow up, find out, and solve possible problems when customers use our products.

FAQ

1. Do you have any MOQ limit for product orders?

Low MOQ, 1 set for sample checking is available. We will give discounted price under large quantity.

2. Is it OK to print my logo on the machine?

Yes. Please inform us formally before our production and confirm the design firstly based on our machines.

3. How does your factory do regarding quality control?

All the products will be 100% checked before shipment.

4. What is the lead time?

It usually takes 7 to 10 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

5. What are your terms of packing?

Generally, we pack our goods in neutral cartons/wrap film under a full container. Or we will make a wooden box. And we also can according to your requirements if any.

6. How to solve quality problems after sales?

Take photos and videos of the problems and send them to us. We will make a satisfactory solution for you within 72 hours when we confirm the problems.

7. How could I get a sample?

The sample will be shipping with you. And you will be charged shipping costs. Express delivery charge depends on the quantity of the samples.

8: Is it possible to load mixed products in one container?

Yes, it’s available.

Hot Searches