- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DONGJIA

-

Voltage:

-

12.27KW

-

Power:

-

12.27KW

-

Weight:

-

5500 KG, 5500KG

-

Product name:

-

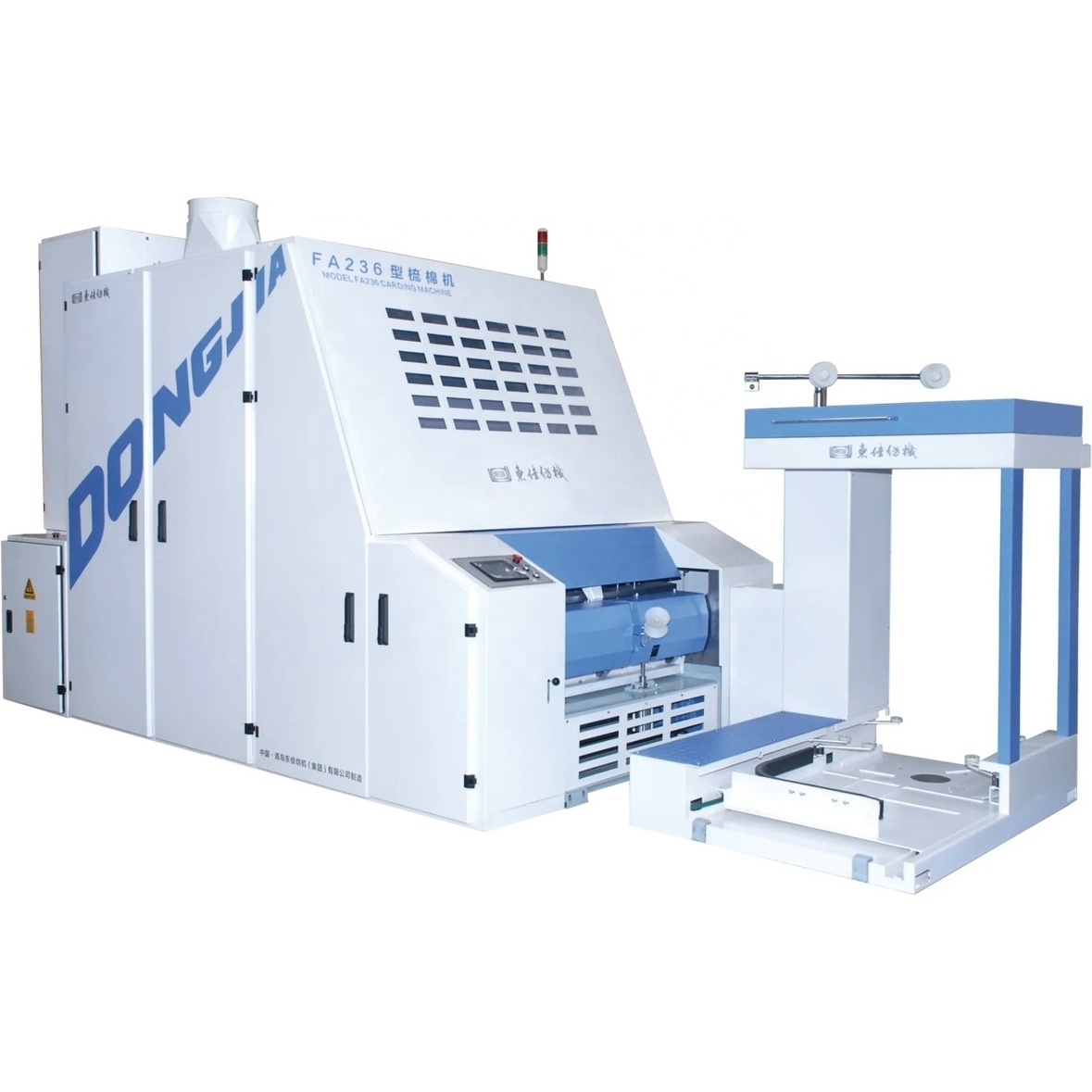

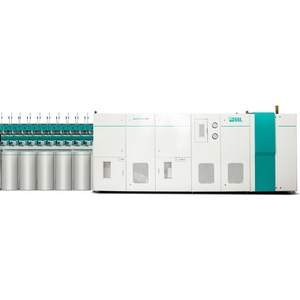

DONGJIA FA236 CARDING MACHINE

-

The car stop:

-

RIGHT-HANDED

-

Cylinder width:

-

1020MM

-

Applicable fiber variety and length:

-

COTTON AND POLYESTER 22-76MM

-

Feeding cotton layer ration:

-

350-720G/M

-

Feeding cotton layer width:

-

920MM

-

Sliver delivey ration:

-

3.5-6.5G/M

-

Installed power:

-

12.72KW

-

Overall size:

-

2928*1974*2196

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Application:

-

textile cashmere, camel, yak, sheep wool, wool

-

Production Capacity:

-

50KG/H

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DONGJIA

-

Voltage:

-

12.27KW

-

Power:

-

12.27KW

-

Weight:

-

5500 KG, 5500KG

-

Product name:

-

DONGJIA FA236 CARDING MACHINE

-

The car stop:

-

RIGHT-HANDED

-

Cylinder width:

-

1020MM

-

Applicable fiber variety and length:

-

COTTON AND POLYESTER 22-76MM

-

Feeding cotton layer ration:

-

350-720G/M

-

Feeding cotton layer width:

-

920MM

-

Sliver delivey ration:

-

3.5-6.5G/M

-

Installed power:

-

12.72KW

-

Overall size:

-

2928*1974*2196

Product Description

FA236 CARDING MACHINE

This machine is used to card, clean and blend loose fibers opened by the blow room system, condense them into uniform slivers after eliminating most cotton neps,impurities and short fibers from them. and then coil them regularly in sliver can for the next process use

Specification

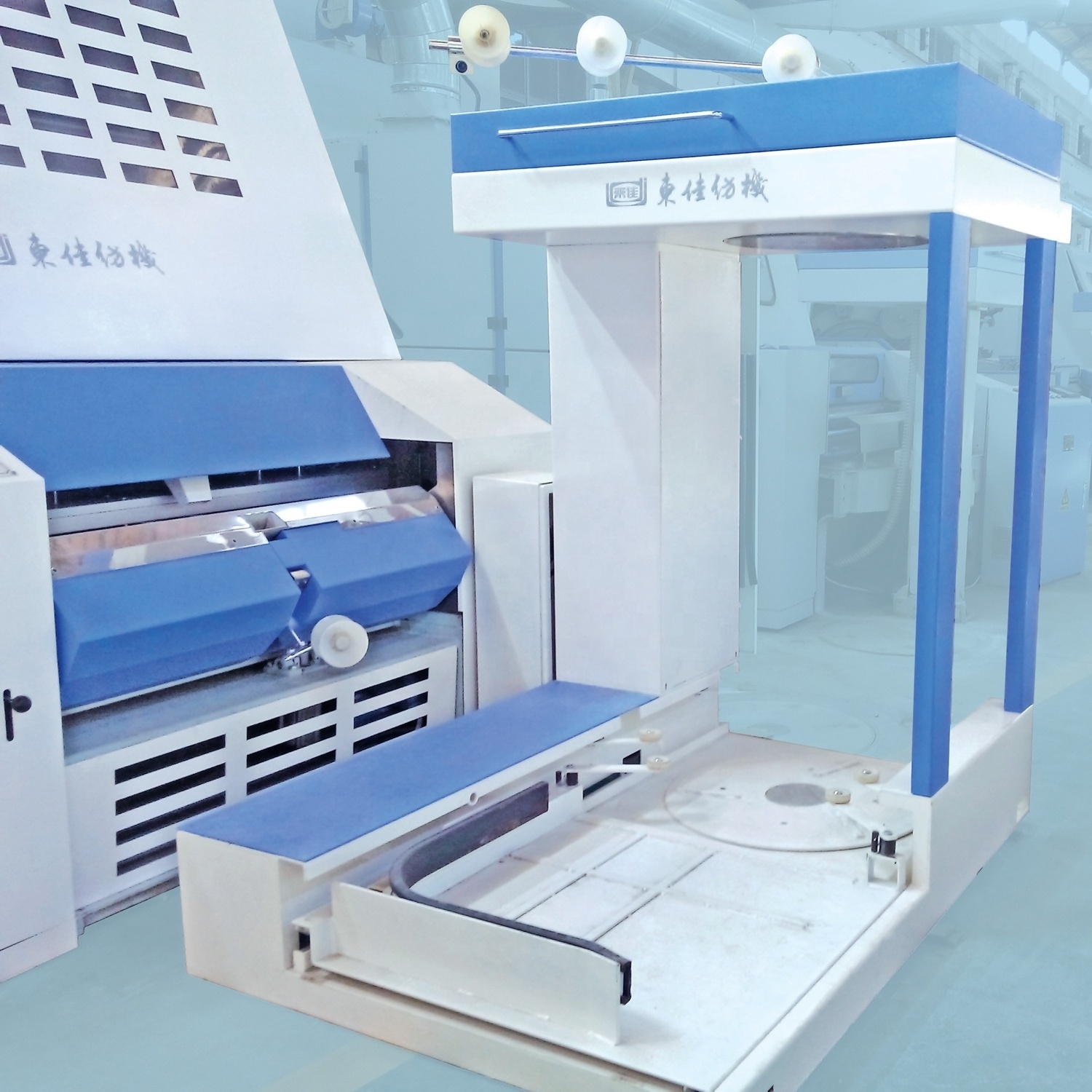

1.Design brand new upper tvpe feed plate and tapered reticular tvpe feed roller, to effectively hold fibers so as to reduce fiber

damage. Unique single licker-in carding segment mechanism, and there are two mote knives and carding segment fixed around the

licker-in to effectively remove short fibers and impurities.

damage. Unique single licker-in carding segment mechanism, and there are two mote knives and carding segment fixed around the

licker-in to effectively remove short fibers and impurities.

simple structure and special processing technology, ensure the accuracy of gauge and the stablity of the whole machine

design of stationary flats and housing plate, which can be flexibly combined and configured according to the requirements of the

process

4.Equipped with 84pcs high-strength aluminium alloy movable flats, synchronous toothed belt drive, light weight, simple structure,

easy and convenient maintance

5.Optimized transmission combination, and most widely used synchronous toothed belt drive,improve the stablity of power transmission

and reduce the noise of equipments

and reduce the noise of equipments

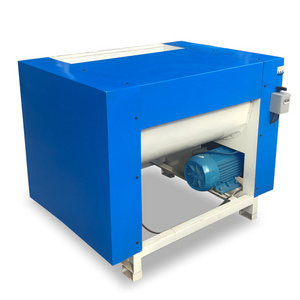

6.At the bottom of cylinder and doffer, the full sealed aluminium alloy housing plate plus positive dust suction pipes, and the high

precision aluminium components with super smooth surface making the cylinder surface airflow distribution more uniform,

effectively reducing airflow interference, and ensuring the smooth passage of fibers.

precision aluminium components with super smooth surface making the cylinder surface airflow distribution more uniform,

effectively reducing airflow interference, and ensuring the smooth passage of fibers.

7.Inclined type three-roller stripping device. cross apron web-collecting device and pneumatic turning type condenser are combined for application together.

requirements.

9.Steel plate roll system for cylinder and doffer, with uniform wall thickness, good balance, nodeformation, light weight, small inertia and easy starting and stopping.

|

item

|

value

|

|

Applicable Industries

|

Manufacturing Plant, Textile Industry, Textile Industry

|

|

Showroom Location

|

India, Russia, Bangladesh, Uzbekistan, Mongolia

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Hot Product 2022

|

|

Warranty of core components

|

1.5 years

|

|

Core Components

|

PLC, Engine, Bearing, Gearbox, Motor, Gear

|

|

Condition

|

New

|

|

Application

|

textile cashmere, camel, yak, sheep wool, wool

|

|

Type

|

Spinning Production Line

|

|

Production Capacity

|

50KG/H

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

DONGJIA

|

|

Spinning Method

|

Rotor Spinning

|

|

Automatic

|

Yes

|

|

Weight

|

5500KG

|

|

Warranty

|

1.5 years

|

|

|

|

Hot Searches