Name: full automatic mixing platform

Brand: OYD brand

Measuring materials. Weighing system uses the gravity center of the pressure sensor structure measuring scale design, measuring scale adopts anti vibration and abrasion-proof , the accuracy of measurement is always guaranteed in construction process. We adopt double-shaft mixer, which has compact structure, beautiful appearance, stable running, convenient operation, high production efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Name:

-

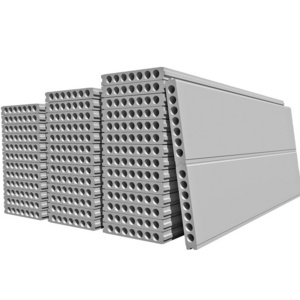

precast concrete molds for sandwich foam panel making machine

-

Electrical components:

-

Siemens or Schneider or famous domestic brand

-

Production capacity:

-

100000 sqm per year - 600000 sqm/year

-

Voltage:

-

380V 50HZ 3phase, adjustable

-

Automation degree:

-

High automatic or normal automatic

-

Land need:

-

1500 sqm - 3000 sqm

-

Machine material:

-

Stainless steel or good carbon steel or alloy

-

After sales Service Provided:

-

Video technical support

-

Production Capacity:

-

1 million sqm

-

Thickness:

-

50-250mm thickness. special sizes need to be customized

Quick Details

-

Weight (KG):

-

10000

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OYADE

-

Name:

-

precast concrete molds for sandwich foam panel making machine

-

Electrical components:

-

Siemens or Schneider or famous domestic brand

-

Production capacity:

-

100000 sqm per year - 600000 sqm/year

-

Voltage:

-

380V 50HZ 3phase, adjustable

-

Automation degree:

-

High automatic or normal automatic

-

Land need:

-

1500 sqm - 3000 sqm

-

Machine material:

-

Stainless steel or good carbon steel or alloy

-

After sales Service Provided:

-

Video technical support

-

Production Capacity:

-

1 million sqm

-

Thickness:

-

50-250mm thickness. special sizes need to be customized

precast concrete molds for sandwich foam panel making machine

eps sandwich panel machine line is in order to adapt to recent development trend of building materials, our company bold innovation design of highly automated production lines, which enables the waste water and materials be reused through elaborate design.

This is our unique design, can full automatically demoulding, 20panels/time. So can save a lot of your labor cost

|

Machinery Parameters

|

|

|

|

Capacity

|

20,000sqm~600,000sqm per year

|

|

|

Thickness

|

50-250mm thickness. special sizes need to be customized

|

|

|

Length

|

2440~3600mm, special sizes need to be customized

|

|

|

Width

|

610mm , special sizes need to be customized

|

|

|

Raw material

|

There are mainly two different types

1. Cement+fly ash/eps/ceramsite/sand, etc (optional, can choose to add or not add) |

|

|

Finished board type

|

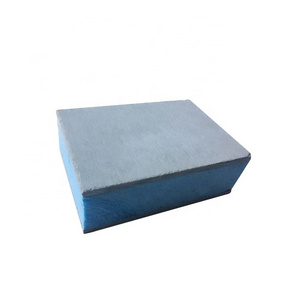

1. Composite board/sandwich board, with surface board

2. Lightweight solid panel, without furface board |

|

|

Surface board types

|

1. Calcium silicate board

2. Fiber cement board 3. Mgo board |

|

|

Electrical

|

There are mainly two different types

|

|

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Full automatic meteriing for raw materials

Each raw material is automatically mesured, so can ensure the eaxct formula.

Name: Pumping system

Brand: OYD brand

Used to paste into the mold, can avoid the air holes.

The feeding machine can be movable, or fixed, matched well with the mold car, easily operate

Name: Full automatic mould car

Brand: OYD brand

Full automatic open and demoulding, no need workers to lift the panel

Q: Do you supply spare parts?

A: Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year.

Q: Will you provide training?

A: The training is free of charge , and our engineer will be on duty to train your worker.

Q: How will you provide installation&commissioning?

A: Will provide 2~8 persons(adjustable according to the degree of automatic )for installation. Engineers team will go with your

project.

Q:How long time for the installation and commissioning?

A: Depend on configuration normally only need 15-25 days. Including workers training.

Warmly welcome you contact me for your questions.