- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1100/500/430mm

-

Weight:

-

550 KG

-

Product name:

-

antalite Ore Spiral Chute Equipment

-

Keywords:

-

Chrome Ore Spiral Chute Equipment

-

Name:

-

Gold Mining Washing Machine

-

Keywords 2:

-

Gold Prospecting Equipment

-

Usage:

-

Gravity Ore Separator

-

Application:

-

Alluvial Gold Washing

-

Color:

-

Gray

-

Other name:

-

spiral chute

-

Recovery rate:

-

80-90%

-

Price:

-

Negotiable

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

hengchang

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1100/500/430mm

-

Weight:

-

550 KG

-

Product name:

-

antalite Ore Spiral Chute Equipment

-

Keywords:

-

Chrome Ore Spiral Chute Equipment

-

Name:

-

Gold Mining Washing Machine

-

Keywords 2:

-

Gold Prospecting Equipment

-

Usage:

-

Gravity Ore Separator

-

Application:

-

Alluvial Gold Washing

-

Color:

-

Gray

-

Other name:

-

spiral chute

-

Recovery rate:

-

80-90%

-

Price:

-

Negotiable

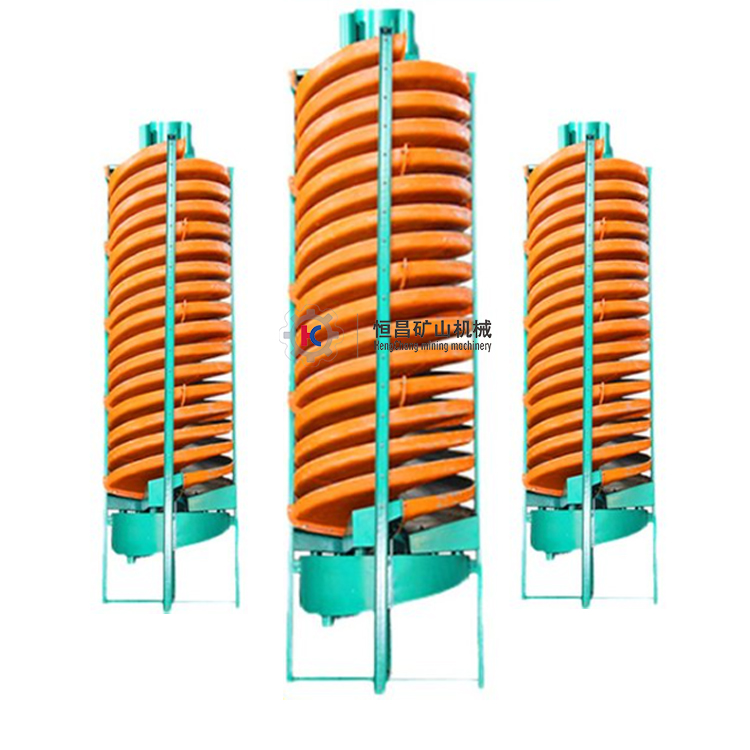

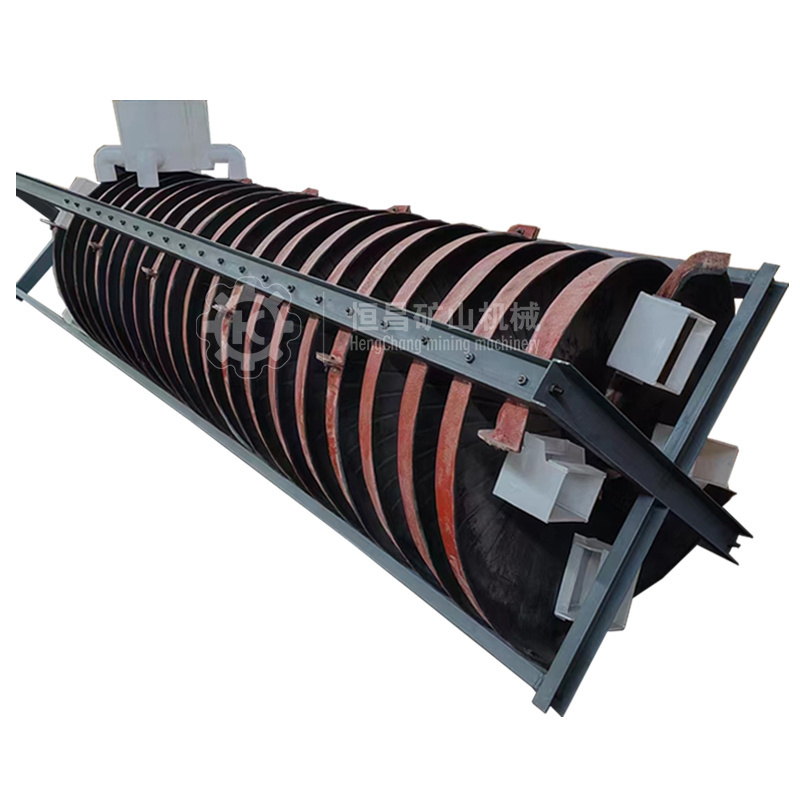

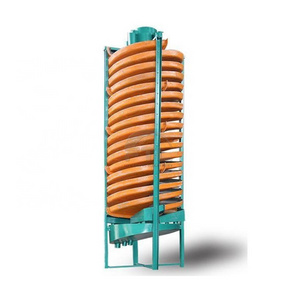

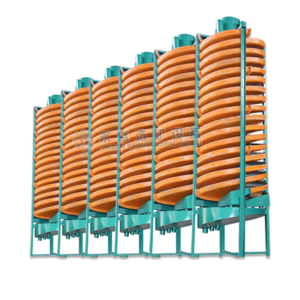

Products Description

Spiral chute is a new gravity separation machine. With the water and action of gravity friction force, minerals would be separated by the different gravity and get heavy, middling and light products.

Spiral concentrator is made of the fiberglass lined with wear-resistant polyurethnane and corundum cover, with feature of anti corrosion, rust and wear resistant.

It's the most suitable equipment for mining and ore beneficiation, especially for placer mining at seaside, riverside, sand bank and stream bank. It is of low water consumption, small floor area, high concentration and recovery ratio, high adaptability, etc.

Spiral concentrator is made of the fiberglass lined with wear-resistant polyurethnane and corundum cover, with feature of anti corrosion, rust and wear resistant.

It's the most suitable equipment for mining and ore beneficiation, especially for placer mining at seaside, riverside, sand bank and stream bank. It is of low water consumption, small floor area, high concentration and recovery ratio, high adaptability, etc.

Product Working Principle

When working, particles are fed to the top of the spiral chute and are separated radially on the basis of density and size as the slurry gravitates downward. In order to have a good separation, there should be a difference in specific gravity of at least 1.0.

Depending upon the material characteristics, a maximum efficiency will usually be reached somewhere in this range. All that is required are some slurry pumps, the slurry to be separated and the banks of spirals with a feed distributor.

Depending upon the material characteristics, a maximum efficiency will usually be reached somewhere in this range. All that is required are some slurry pumps, the slurry to be separated and the banks of spirals with a feed distributor.

Product Features

1. Reasonable structure and small occupation area.

2.High recovery, high efficiency, and precise separation.

3.Light in weight, rust and corrosion resistant.

4.Simple installation and Minimal maintenance requirements.

5.Low operating cost and long operating life.

6.Reliable running with minimal operator attention.

7.Strong adaptability to fluctuation of feeding amount, density, size and grade.

2.High recovery, high efficiency, and precise separation.

3.Light in weight, rust and corrosion resistant.

4.Simple installation and Minimal maintenance requirements.

5.Low operating cost and long operating life.

6.Reliable running with minimal operator attention.

7.Strong adaptability to fluctuation of feeding amount, density, size and grade.

Product Structure

Product Paramenters

|

Model

|

BLL-1500

|

BLL-1200

|

BLL-900

|

BLL-600

|

BLL-400

|

|

Outside Diameter

(mm)

|

1500

|

1200

|

900

|

600

|

400

|

|

Screw Pitch

(mm)

|

900, 675

|

900, 720, 540

|

675, 540, 405

|

450, 360, 270

|

240, 180

|

|

Pitch Diameter Ratio

|

0.48, 0.36

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.6, 0.45

|

|

Lateral slope

(degree)

|

9°

|

9°

|

9°

|

9°

|

9°

|

|

Max. Screw Numbers

|

4

|

4

|

4

|

2

|

2

|

|

Feed Size (mm)

|

0.8 ~0.037

|

0.3~0.03

|

0.3 ~0.03

|

0.2~0.02

|

0.2 ~0.02

|

|

Feed Density (%)

|

30 ~55

|

25 ~55

|

25 ~55

|

25 ~55

|

25 ~55

|

|

Capacity (t/h)

|

6~8

|

4~6

|

2~3

|

0.8~1.2

|

0.15~0.2

|

|

Length (mm)

|

1600

|

1360

|

1060

|

700

|

460

|

|

Width (mm)

|

1600

|

1360

|

1060

|

700

|

460

|

|

Height (mm)

|

5300

|

5230

|

4000

|

2600

|

1500

|

|

Weight (kg)

|

850/800

|

700/650/600

|

450/400/350

|

150/120/100

|

50

|

Successful Case

Hot Searches