- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LC-2668-ES

-

Feature:

-

very smoothness

-

Product name:

-

Roller coating curable varnish liquid

-

coating method:

-

offset uv printing, flexo UV coating and off-line uv coating machine

-

smell:

-

lowest smell

-

gloss:

-

high gloss

-

application method:

-

roller

-

state:

-

liquid coating

-

usage:

-

printed surface coating

-

curing ways:

-

UV lamp

-

main raw material:

-

Epoxy acrylic resin

Quick Details

-

Printing Type:

-

Offset printing

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LCCX

-

Model Number:

-

LC-2668-ES

-

Feature:

-

very smoothness

-

Product name:

-

Roller coating curable varnish liquid

-

coating method:

-

offset uv printing, flexo UV coating and off-line uv coating machine

-

smell:

-

lowest smell

-

gloss:

-

high gloss

-

application method:

-

roller

-

state:

-

liquid coating

-

usage:

-

printed surface coating

-

curing ways:

-

UV lamp

-

main raw material:

-

Epoxy acrylic resin

gloss UV OPV Roller coating curable varnish liquid printed surface coating for Offset or flexo printing

printed surface coating,gloss UV OPV,Roller coating curable varnish liquid

Printed surface coating UV OPV LC-2668-ES

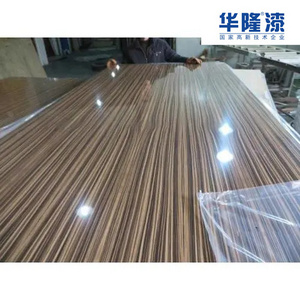

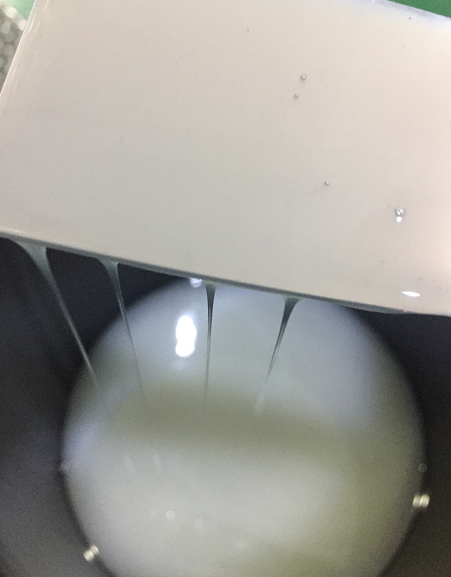

LC-2668-ES is a type of UV OPV for prined surface coating, widely used for paper, in-mold label, and stickers surface coating,one kind of UV-sensitive varnish based on the main raw material as Epoxy acrylic acid, don’t contain solvent. After roller coating the liquid varnish, through UV light curing then change into a stable solid state. This product apply for paper, pp, PE and the other synthetic paper substrate’s coating, have the features of high gloss, fastness, very smoothness, good leveling etc.

General properties:

| Appearance | transparent to slightly white liquid |

| solid content (%) | 100% |

| Gloss degree | above 93 degrees |

| viscosity(S.t cup 4#25℃) | 35±5s, can adjust |

| drying condition | original varnish 30±3mj/cm 2 |

| odor | lower smell |

| hand feeling | very smooth |

| wearing resistance | 4 pounds 600 times |

Operating information:

1. Temperature: it can be used in room temperature with no solvent. If used under 18℃, please warm to 30℃ for a better varnish effect, or keep the tank at 50℃ + 5℃. The top heating temperature is within in 60 ℃.

2. During downtime, can use alcohol, isopropyl alcohol, ethyl acetate or cleaning solvent such as toluene to clean the rollers.

3. Apply coating quantity: according to the paper, usually a t 5~8g/m 2 (dry weight).

Features, application and construction :

|

features |

lower smell, high gloss, good hand feeling, very smooth, good flexibility, prevent die-cutting edge breakage, antistatic. |

|

application |

widely used for in mold labeling uv coating, or in mold film uv gloss and the other labels. |

|

construction |

1. in-line offset uv printing machine and flexo uv printing 2. Off-line coating, separate uv coating, old three-roller machine, spot uv machine & anilox roller machine. 3. Drying method: ultraviolet mercury lamp. |

Security issues:

1.After curing, this product is non-toxic and non-irritating, but if skin touched with the UV liquid, must wash with alkaline soap more than three time within 30 minutes Asap. When clothes touched, should change clothes immediately, avoid skin burn caused by a long time touched.

2.Keep the workplace in good ventilation.

20KG/barrel, 25KG/barrel or 200KG/barrel, also can meet special packing specification.

Storage:

1.Should avoid sunlight & high-heat, don’t store with oxide materials. Store in shady and cool, dry and good ventilation condition’s place.

2.Shelf time are 12 months from date of production.

3.Suggested storage temperature environment is 5℃-30℃.