- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

1500 mm

-

Travel (Y Axis)(mm):

-

3000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Unique CNC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6000x3000x1200mm

-

Weight (KG):

-

5000

-

Weight:

-

6000kg

-

Power(W):

-

20KW

-

Model No.:

-

U-R3060EPS

-

Working area:

-

3000x6000x1200mm

-

Machine structure:

-

heavy duty, thick steel tube welded

-

Table structure:

-

thick aluminum table with T-slot

-

Spindle:

-

9KW,air cooled auto tool change,0-24000rpm

-

Spindle rotate degree:

-

±90 degrees

-

Driving system:

-

Yaskawa servo and driver,Shimpo reducer

-

Transmit system:

-

XY adopt Germany made gear rack,Z adopt Taiwan made ball screws

Quick Details

-

Working Table Size(mm):

-

1500x3000

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

0 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

1500 mm

-

Travel (Y Axis)(mm):

-

3000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Unique CNC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6000x3000x1200mm

-

Weight (KG):

-

5000

-

Weight:

-

6000kg

-

Power(W):

-

20KW

-

Model No.:

-

U-R3060EPS

-

Working area:

-

3000x6000x1200mm

-

Machine structure:

-

heavy duty, thick steel tube welded

-

Table structure:

-

thick aluminum table with T-slot

-

Spindle:

-

9KW,air cooled auto tool change,0-24000rpm

-

Spindle rotate degree:

-

±90 degrees

-

Driving system:

-

Yaskawa servo and driver,Shimpo reducer

-

Transmit system:

-

XY adopt Germany made gear rack,Z adopt Taiwan made ball screws

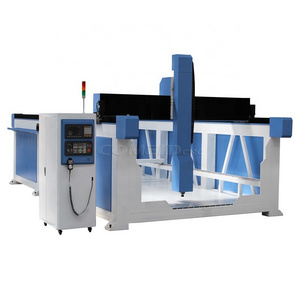

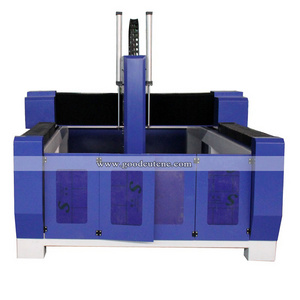

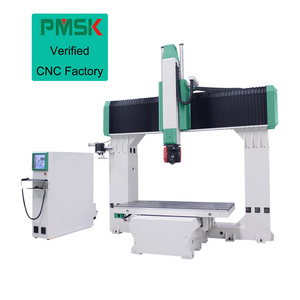

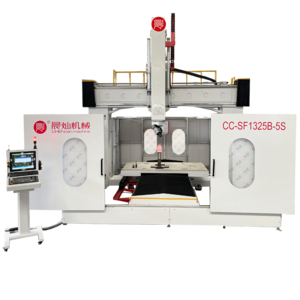

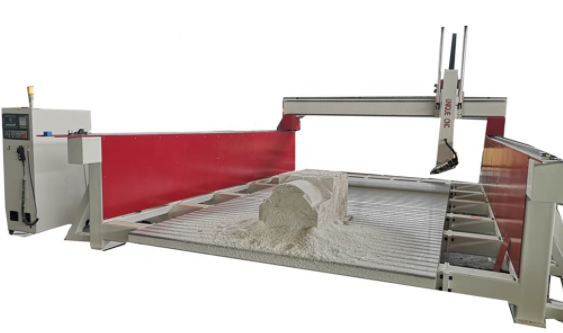

4 Axis EPS CNC Router Machine for Foam EPS Styrofoam Wood Aluminium Mold with rotate spindle

Applications of the 4 Axis EPS CNC Router machine:

4 axis EPS CNC router machine is used for aluminium mold, wooden mold, EPS and non-metallic carbon materials, automotive foam

mold, aviation mold, trains mold, 3D musical instruments, bumper, bonnet interior trim mold.

Configurations of 4 Axis EPS CNC router machine:

1. Working area is 3000x6000x1200mm.

2. The spindle can rotate ±90 degrees

2. 9.0kw air cooled auto tool change spindle

3. Taiwan Syntec controlling system.

4. Japan Yaskawa servo motor and drivers.

5. Delta inverter from Taiwan.

6. Taiwan HIWIN square rails.

7. Japan Omron limited switch.

8. Divided very rigid durable machine structure

9. Working table:T-slot working table.

10. Japan Shimpo reducer.

11. Auto lubricate system

4 axis EPS CNC router machine is used for aluminium mold, wooden mold, EPS and non-metallic carbon materials, automotive foam

mold, aviation mold, trains mold, 3D musical instruments, bumper, bonnet interior trim mold.

Configurations of 4 Axis EPS CNC router machine:

1. Working area is 3000x6000x1200mm.

2. The spindle can rotate ±90 degrees

2. 9.0kw air cooled auto tool change spindle

3. Taiwan Syntec controlling system.

4. Japan Yaskawa servo motor and drivers.

5. Delta inverter from Taiwan.

6. Taiwan HIWIN square rails.

7. Japan Omron limited switch.

8. Divided very rigid durable machine structure

9. Working table:T-slot working table.

10. Japan Shimpo reducer.

11. Auto lubricate system

Parameters of the 4 axis EPS cnc router:

|

No.

|

Description

|

Parameter

|

|

1

|

Model No.

|

U-R3060EPS

|

|

2

|

Working area

|

3000x6000x1200mm

|

|

3

|

X,Y,Z reposition accuracy

|

±0.15mm

|

|

4

|

Machine structure

|

heavy duty, thick steel tube welded

|

|

5

|

Table structure

|

thick aluminum table with T-slot

|

|

6

|

Spindle

|

9KW, air cooled,auto tool change,0-24000rpm

|

|

7

|

Spindle rotate degree

|

±90 degrees

|

|

8

|

Driving system

|

Yaskawa servo and driver, Shimpo reducer

|

|

9

|

Transmit system

|

X Y adopt Germany made gear rack, Z adopt Taiwan made ball screws

|

|

10

|

Control system

|

Syntech

|

|

11

|

Idling speed

|

X,Y: 35m/min, Z: 15m/min

|

|

12

|

Working speed

|

X,Y:20m/min, Z: 8m/min

|

|

13

|

Command

|

G code

|

|

14

|

Programming software

|

Powermill, UG, Rhino with post process

|

Samples made by the 4 axis EPS cnc router:

Our Advantages

01 Professional Advantage

Nearly 13 years of professional production and export experience. Cooperation with the largest customers from some countries.

02 Quality Assurance

All the products have the cetificate of ISO and CE approval, Guaranteed quality.

03 Fast Delivery

There are a large number of products in stock, so generally we can ship goods in about 3-5 days.

04 Price Advantage

Good quallity, resonable price, on time shipping and best service for each customers.

05 Customized Service

Tailor-made for each customer's requirements.

06 After-Sale Advantages

Long time guarantee period and 24 hours online service.

Our certificate

FAQ

Q Why should we choose you ?

A

If you choose us, you will get top quality, best service, reasonable price and reliable warranty.

Q I'm not familiar with the machine,how to choose?

A

Just tell us materials, thickness and working size, I will recommend the suitable machine.

Q How to operate the machine?

A

We will deliver English manual and video with the machine to you. If you still need our further help, please contact us.

Q Can I get the sample to check quality of machine ?

A

Of course. Please provide your logo or design to us, free samples can be provided for you.

Q Can the machine be customized according my requirements?

A

Sure, we have a strong technical team and have rich experience. Our goal is to make you satisfied.

Q Can you arrange the shipment for us?

A

Of course. We can arrange the shipment for our clients accordingly by sea and air. Trading terms FOB, CIF, CFR are available.

Hot Searches