- Product Details

- {{item.text}}

Quick Details

-

Feature:

-

Moisture Proof

-

Industrial Use:

-

Industry

-

Place of Origin:

-

China

-

Model Number:

-

19um

-

Color:

-

Transaprent

-

Thickness:

-

19mic

-

Width:

-

Customized

-

Application:

-

FRP sheet panel

Quick Details

-

Material:

-

BOPET

-

Type:

-

Stretch Film

-

Use:

-

fiberglass sheet panel

-

Feature:

-

Moisture Proof

-

Industrial Use:

-

Industry

-

Place of Origin:

-

China

-

Model Number:

-

19um

-

Color:

-

Transaprent

-

Thickness:

-

19mic

-

Width:

-

Customized

-

Application:

-

FRP sheet panel

Product Description

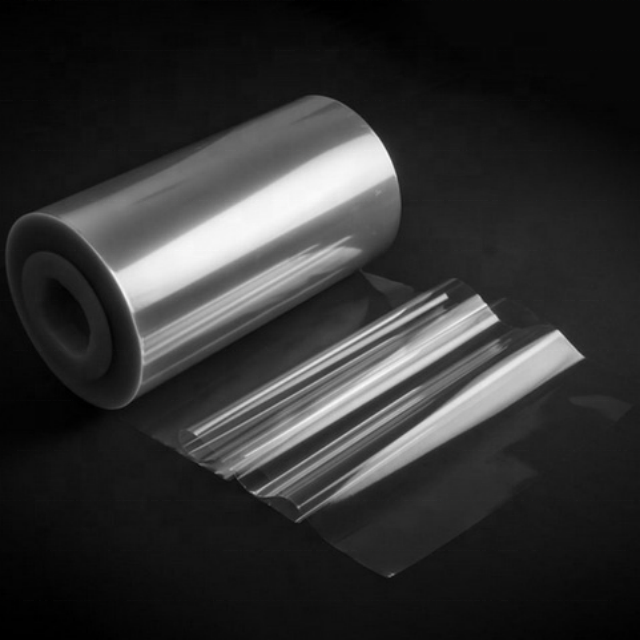

Polyester film(Mylar film) is used in fiberglass reinforced pipe, tank, container for the mould releasing and surface calendaring.

Inside of polyester film is covered with silicone oil, it is more effective to keep mould release and surface calendar.

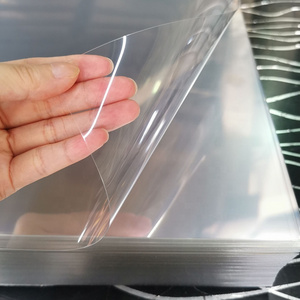

The thickness of polyester film varies from 19micro meters to 100micro meters.

General thickness: 19um, 25um, 50um, 100um.

The width can be arranged according to customer' s requirements.

General width: 910mm,1170mm,1370mm.

Inside of polyester film is covered with silicone oil, it is more effective to keep mould release and surface calendar.

The thickness of polyester film varies from 19micro meters to 100micro meters.

General thickness: 19um, 25um, 50um, 100um.

The width can be arranged according to customer' s requirements.

General width: 910mm,1170mm,1370mm.

Specification

|

Item

|

Unit

|

Typical Value

|

Test Method

|

|

Thickness

|

um

|

19

|

ASTM D 374

|

|

Tensile Strength(MD/TD)

|

Mpa

|

220/210

|

ASTM D 882

|

|

Break elongation(MD/TD)

|

%

|

100/100

|

ASTM D 882

|

|

ModuIUS(MD/TD)

|

Mpa

|

4000/4000

|

ASTM D 882

|

|

Shrinkage(MD/TD)150℃

30min |

%

|

1.5/0

|

ASTM D 1204

|

|

Haze

|

%

|

3

|

ASTM D 1003

|

Packing & Delivery

Hot Searches