- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TDX

-

Weight (KG):

-

40

-

Product name:

-

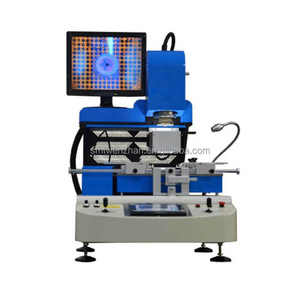

BGA Rework station machine

-

MODEL:

-

TDX-580C

-

POWER:

-

AC 220V±10% 50/60Hz

-

Overall dimension:

-

L650 X W630 X H850mm

-

PCB size:

-

Max450 X 390mm Min10 X 10 mm

-

PCB thickness:

-

0.3-5mm

-

BGA chip size:

-

Max 60mm X 60mm Min 1mm X 1mm

-

Electrical material:

-

Driving motor + PLC smart temp.controller + color touch screen

-

Total power:

-

5300w

-

Weight of machine:

-

60kg

Quick Details

-

Marketing Type:

-

New Product

-

Core Components:

-

smd rework station

-

Place of Origin:

-

China

-

Brand Name:

-

TDX

-

Weight (KG):

-

40

-

Product name:

-

BGA Rework station machine

-

MODEL:

-

TDX-580C

-

POWER:

-

AC 220V±10% 50/60Hz

-

Overall dimension:

-

L650 X W630 X H850mm

-

PCB size:

-

Max450 X 390mm Min10 X 10 mm

-

PCB thickness:

-

0.3-5mm

-

BGA chip size:

-

Max 60mm X 60mm Min 1mm X 1mm

-

Electrical material:

-

Driving motor + PLC smart temp.controller + color touch screen

-

Total power:

-

5300w

-

Weight of machine:

-

60kg

Product Description

|

|

WZ-580

|

WZ-620

|

WZ-650

|

WZ-750

|

|

Power

|

AC 220V±10% 50Hz

|

AC 220V±10% 50/60Hz

|

AC 110V / 220V±10% 50/60Hz

|

AC 110V / 220V±10% 50/60Hz

|

|

Overall dimension

|

L500mm*W590mm*H650mm

|

L650×W630×H850mm

|

L 600*W 640*H 850mm

|

L830×W670×H850mm

|

|

PCB size

|

Max 400mm*370mm Min 10mm*10mm

|

Max 450×390mm Min 10×10 mm

|

Max 400mm*370mm Min 10mm*10mm

|

MAX 550×480mm MIN 10×10mm( customizable )

|

|

BGA chip size

|

Max 60mm*60mm Min 1mm*1mm

|

Max 60mm*60mm Min 1mm*1mm

|

MAX 70*70mm -MIN 1*1 mm

|

Max 60mm*60mm Min 1mm*1mm

|

|

PCB thickness

|

0.3-5mm

|

0.3-5mm

|

0.3 - 5mm

|

0.5-8mm

|

|

Weight of machine

|

40KG

|

60kg

|

60KG

|

90kg

|

|

Warranty

|

1 year

|

1 year

|

1 year

|

1 year

|

|

Total power

|

4800W

|

5300w

|

6400W

|

6800W

|

|

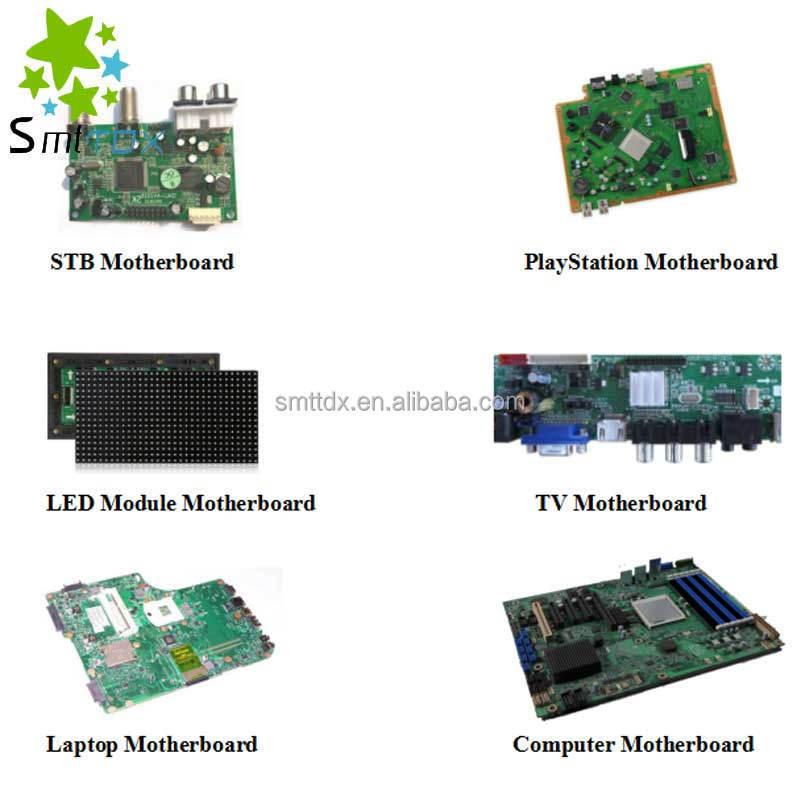

Usage

|

Repair chips / phone motherboard etc

|

Repair chips / phone motherboard etc

|

Repair chips / phone motherboard etc

|

Repair chips / phone motherboard etc

|

|

Electrical material

|

Touch screen+Temperature control module+PLC control

|

Driving motor+PLC smart temp.controller+color touch screen

|

Driving motor + smart temp. controller + color touch screen

|

Touch screen+Temperature control module+PLC control

|

|

Location way

|

V-shape card slot+Universal jigs

|

V-shape card slot+Universal jigs

|

V-shape card slot+Universal jigs

|

V-shape card slot+Universal jigs

|

Introduction:

BGA (Ball Grid Array) Rework station is a specialized equipment used for the removal and installation of BGA components on circuit boards. It is widely used in electronics manufacturing and repair industries. BGA components are complex and challenging to handle due to their array of tiny solder balls on the underside. The BGA Rework station provides a controlled and precise process for the successful rework of BGA components.

Usage

:

Setting up the Rework Station:

Ensure the work area is clean and well-ventilated.

Place the BGA Rework station on a stable surface.

Connect the required power supply and turn on the station.

Allow the station to warm up for the recommended duration.

Adjust the temperature and airflow settings based on the specific BGA component and circuit board requirements.

Preparing the BGA Rework:

Inspect the circuit board and identify the BGA component to be reworked.

Clean the area around the BGA component to remove any debris or excess solder.

Apply a suitable flux to the BGA component to aid in the reflow process.

Removal Process:

Apply an appropriate preheating temperature to the circuit board to ensure uniform heating.

Position the circuit board securely on the rework station.

Align the BGA Rework nozzle with the BGA component.

Activate the nozzle's hot air and commence heating.

Observe the reflow process and ensure the solder balls become molten.

Once the solder balls are molten, remove the BGA component using appropriate tools such as a vacuum pen or tweezers.

Carefully clean the site to remove any residue or excess flux.

Replacement Process:

Inspect the replacement BGA component for any defects or damage.

Apply a thin layer of solder paste to the BGA component pads on the circuit board.

Align the replacement BGA component with the pads on the circuit board.

Place the replacement component onto the circuit board using appropriate tools.

Ensure proper alignment and positioning.

Apply an appropriate preheating temperature to the circuit board.

Activate the nozzle's hot air and commence heating to reflow the solder.

Observe the solder balls melting, ensuring a secure connection.

Once the solder balls have solidified, remove the circuit board from the rework station and inspect for proper installation.

Post-Rework Inspection:

Inspect the solder joints under a magnifying glass or microscope for any defects or abnormalities.

Perform electrical testing, if applicable, to verify the functionality of the reworked BGA component.

Conduct a thorough visual inspection of the entire circuit board to ensure no other issues were introduced during the rework process.

Conclusion:

BGA Rework station is a crucial tool in the electronics manufacturing and repair industry. It allows for the safe and efficient removal and installation of BGA components on circuit boards. By following proper procedures, one can achieve reliable and high-quality rework results. Proper temperature control, precise alignment, and thorough inspections are essential for successful BGA rework.

Specification

|

Weight (KG)

|

60

|

|

Showroom Location

|

United Kingdom, United States

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

BGA Rework station

|

|

Place of Origin

|

China

|

|

Brand Name

|

WZ

|

|

Model Number

|

WZ-580C WZ-620C WZ-650C WZ-650C WZ-750C

|

|

Warranty

|

1 Year

|

|

Product name

|

BGA Rework station machine

|

|

MODEL

|

WZ-580C WZ-620C WZ-650C WZ-650C WZ-750C

|

|

POWER

|

AC 220V±10% 50/60Hz

|

|

Overall dimension

|

L650 X W630 X H850mm

|

|

PCB size

|

Max450 X 390mm Min10 X 10 mm

|

|

PCB thickness

|

0.3-5mm

|

|

BGA chip size

|

Max 60mm X 60mm Min 1mm X 1mm

|

|

Electrical material

|

Driving motor + PLC smart temp.controller + color touch screen

|

|

Total power

|

5300w

|

|

Weight of machine

|

60kg

|

Packing & Delivery

CARTON BOX

Hot Searches