- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WHGCM

-

Voltage:

-

110V 220V 380V

-

Power:

-

12KW-75KW

-

Dimension(L*W*H):

-

as per drawing

-

Weight:

-

500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Manufacture License of Special Equipment:

-

A1 & A2

-

Working Volume:

-

30m3 Max

-

Working Pressure:

-

10Mpa Max

-

Ultimate Vacuum:

-

6*10-2Mpa

-

Sealing Type:

-

Magnetic Seal, Packing Seal, Mechanical Seal

-

Heating Type:

-

Electric, Water Recycling, Thermal Oil, Steam or Far Infrared heating

-

Mixing Shaft:

-

Self-lubricating wear-resistant sleeve, suitable for mix various media

-

Control Device:

-

PID, PLC automatic controller

-

Certification:

-

CE ISO

Quick Details

-

Capacity:

-

3000L

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WHGCM

-

Voltage:

-

110V 220V 380V

-

Power:

-

12KW-75KW

-

Dimension(L*W*H):

-

as per drawing

-

Weight:

-

500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Manufacture License of Special Equipment:

-

A1 & A2

-

Working Volume:

-

30m3 Max

-

Working Pressure:

-

10Mpa Max

-

Ultimate Vacuum:

-

6*10-2Mpa

-

Sealing Type:

-

Magnetic Seal, Packing Seal, Mechanical Seal

-

Heating Type:

-

Electric, Water Recycling, Thermal Oil, Steam or Far Infrared heating

-

Mixing Shaft:

-

Self-lubricating wear-resistant sleeve, suitable for mix various media

-

Control Device:

-

PID, PLC automatic controller

-

Certification:

-

CE ISO

Recommend Products

Certifications

Product Paramenters

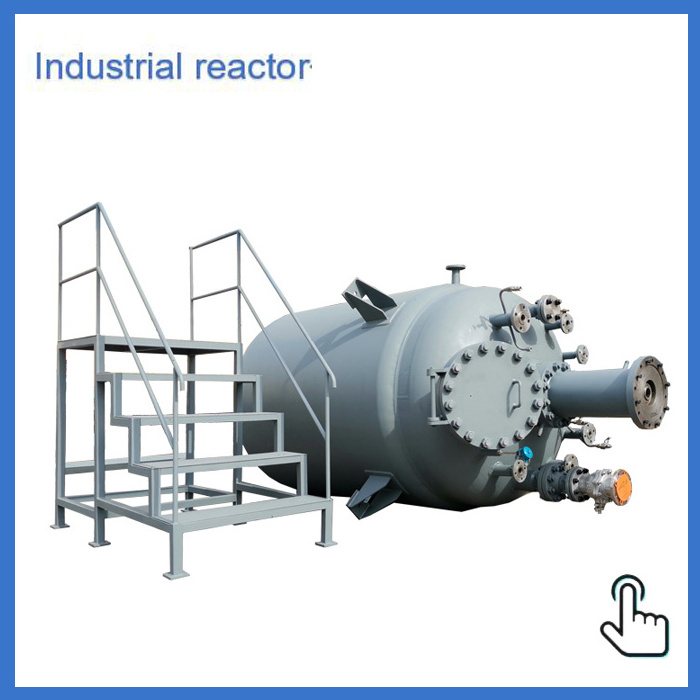

Typical Reactor Appearance

It's normally a tank style, consists of motor, reducer, magnetic seal (or other seal) kettle lid ports (with valves and sensors).

A jacket is covered outside reactor kettle for cooling and heating purpose. Discharging usually happens on bottom through a valve in pneumatic or electric type.

A jacket is covered outside reactor kettle for cooling and heating purpose. Discharging usually happens on bottom through a valve in pneumatic or electric type.

|

Technical Parameters

|

|

|

|

|

||||

|

Model No.

|

GSH500~20,000L

|

|

|

|

||||

|

Scale

|

Industrial Reactor

|

|

|

|

||||

|

Volume (L)

|

500~20,000L

|

|

|

|

||||

|

Working pressure (MPa)

|

Negative pressure -0.1~9.8

|

|

|

|

||||

|

Working temperature (°C)

|

-196~350

|

|

|

|

||||

|

Stirring speed (r/min)

|

0~1000

|

|

|

|

||||

|

Motor power (KW)

|

5.5~45

|

|

|

|

||||

|

Heating power (KW)

|

48~90

|

|

|

|

||||

|

Heating type

|

Electric heating, far infrared heating, high frequency heating.

Water recycling, thermal oil or steam through jacket by constant temperature slot. |

|

|

|

||||

|

Seal type

|

Magnetic seal, mechanical seal, packing seal.

|

|

|

|

||||

The motor& reducer

The paddle

The manhole

Products Description

Industrial reactor

Industrial Reactor helps various reactions between gas, liquid and solid materials happen inside tank, under certain temperature and pressure. It can mix and heat material, the whole process is monitored by PID or PLC controller. Therefore they have ports for sensors and material input and output, widely used in many industrial range. To speed up reaction rate, a pressure reactor is commonly used.The reactor lid and reactor body are connected by bolts and nuts on flanges, for bigger scale, kettle head and kettle body are welded together, open Man Hole on top head for assembly repair and maintain. Various open lid ports give reactor useful functions for easy operation and multi-functional.Kinds of mixer style for different working mediums, can be custom made as per request.

Magnetic Stirrer

* 100% Sealing. Zero leakage.* Zero emission of hazardous fluids.

* Suitable for pressure fluctuations.

* Various capacities available.

* Compact Design.

* Suitable for pressure fluctuations.

* Various capacities available.

* Compact Design.

Electric heating

*Several group electric heating rod.

*Conduct heating oil

Customize for you

Reasonably customize the nozzle port and orientation, including:*Liquid inlet, gas inlet, solid inlet, safety device, vent

outlet... etc.

outlet... etc.

Internal Structure

*Internal spiral coils optionalQuick coolings for material*Dip tupe device

Used for up discharging

*Gas distributor

Hydrogen emission distribution

*Gas-liquid mixing impeller

Propeller, turbine, gas inducing impeller

Used for up discharging

*Gas distributor

Hydrogen emission distribution

*Gas-liquid mixing impeller

Propeller, turbine, gas inducing impeller

Agitator

*Different impeller type available for specific mixing mission.

*Special impeller design according to process condistions*Propeller, turbine type, gassing stirrer, anchor type , frame type,. etc.

*Special impeller design according to process condistions*Propeller, turbine type, gassing stirrer, anchor type , frame type,. etc.

Controller PID or PLC

For control mixing speed, heating temperature or other instruments connect with reactor.

It can be the ex-proof type.

Other Reactor Styles

For different reaction process, the reactor structure have much different, like cone bottom reactor, spherical head reactor,

half-coil jacket reactor, etc.

half-coil jacket reactor, etc.

Details Images

KETTLE BODY

INTERNAL SPIRAL

MAGNETIC COUPLER

KETTLE LID

KETTLE INSIDE

INSERT TUBE

BOTTOM HEAD

COOLING COIL

MOTOR&REDUCER

Customer Photos

Hot Searches