- Product Details

- {{item.text}}

Quick Details

-

thickness:

-

14mm,16mm

-

oil yield:

-

15%-70%

-

output oil as tyre:

-

45 percent

-

Model of cooling:

-

Water cooling

-

Material:

-

waste tyre/rubber/plastic

-

Output:

-

2-10tons

-

Space Needed:

-

400-500㎡

-

Capacity:

-

5tons,10 tons

Quick Details

-

Place of Origin:

-

Henan, China

-

Product name:

-

Waste Oil Pyrolysis Plant

-

Rotation speed:

-

0.8r/min

-

thickness:

-

14mm,16mm

-

oil yield:

-

15%-70%

-

output oil as tyre:

-

45 percent

-

Model of cooling:

-

Water cooling

-

Material:

-

waste tyre/rubber/plastic

-

Output:

-

2-10tons

-

Space Needed:

-

400-500㎡

-

Capacity:

-

5tons,10 tons

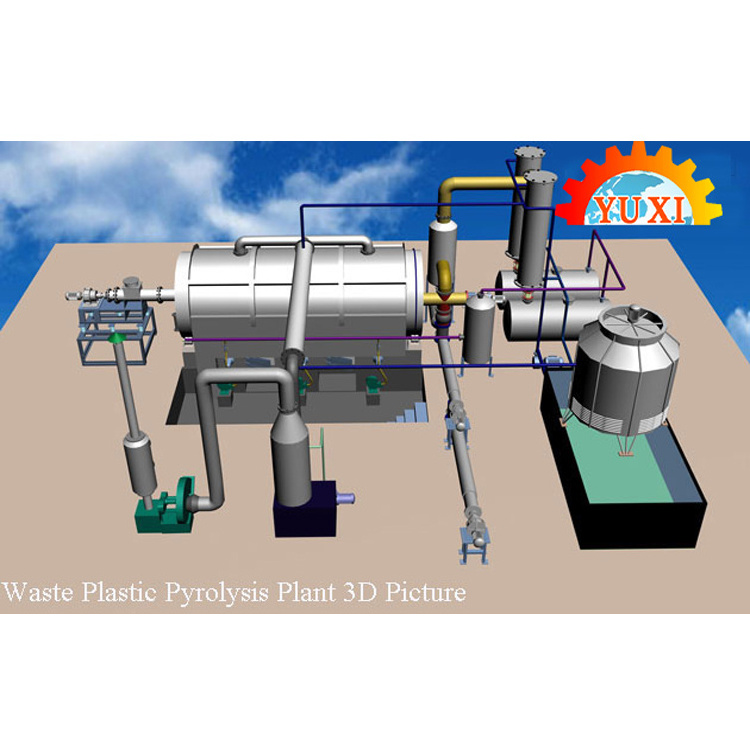

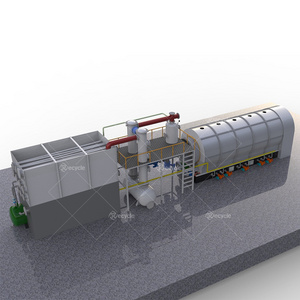

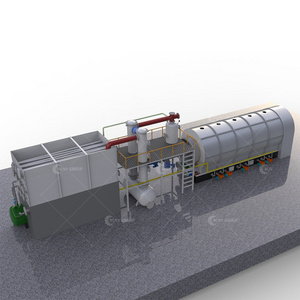

Fully automatic continuous waste plastic tyre pyrolysis to oil

♣ Product Description of waste tyre pyrolysis plant

♥. Waste tire/plastic pyrolysis plant for fuel oil is a new type of tyre oil treatment machine researched by our company through many times of experiment combined with the actual situation. The whole treating process is going under low temperature. It can effectively remove the tiny particles and Colloidal matter in the tyre oil, and meanwhile it can remove the odour of the oil, and finally makes the oil color looks clean and transparent and improve the economic value. It features high recycling rate, low costs of energy consumption, good oil processing ability. It is suitable for purification of tyre pyrolysis oil.

♥. Pyrolysis Process involves the conversion of assorted polymers into petroleum by a much less precise thermal depolymerization process. Such a process would be able to accept almost any polymer or mix of polymers, including thermoset materials such as vulcanized rubber tires and the biopolymers in feathers and other agricultural waste. Like natural petroleum, the chemicals produced can be made into fuels as well as polymers.

♣ The production line of waste tyre pyrolysis plant

Waste tyre crushing system →Constant temperature heating system →Continuous pyrolysis system →Carbon black production system →Gas purification system →Flue gas purification system →Control system →Oil distillation system →Oil

♣ End product of waste tyre pyrolysis plant

| No. | Name | Rate of output use | |

| 1 | Tyre oil | 45% |

Can directly to sell Can use distillation equipment get gasoline and diesel Can be used as a fuel |

| 2 | Carbon black | 30% |

Can directly to sell Using carbon black refining equipment to get fine carbon black You can use the carbon black particle granulation equipment |

| 3 | Scrap steel wire | 15% |

Can directly to sell Can use hydraulic baling press do produce piece of easy transportation and storage |

| 4 | Flue gas | 10% |

Can pass gas spray gun used as fuel Excess gas can be storage system storage |

♥. Carbon black: used for construction bricks with clay also can be used as fuel.

♥. Fuel oil: Widely used as fuel oil in industries such as steel and iron factories, ceramics or chemical industries or hotels, restaurants etc. or used for generators to get electricity.

♥. Steel wires: Sold or reprocessing

♥. Combustible gas: Can be recycled and used during process as fuel.

♣ Technical Parameters

| Capacity | 1 ton , 5 ton , 6ton , 8 ton , 10 ton , 15 ton , 20 ton ,30 ton |

| Operating pressure | Constant pressure |

| Machine type | Batch type & continuous type |

| Reactor rotate speed | 0.4 turn/ minute |

| Space for machine | 30-40m width , 10m width |

| Noise | <75DB |

| Power consumption | 20 KW per hour |

| Pyrolysis reactor size | 2800MM*6600MM (10 ton) |

| Certificates | ISO, CE |

1.The size for the equipment :

Device itself covers an area of 300 square meters (25 meters long / 12 m wide), and covers an area of raw materials, end products piled up, simply rest area, office area and workers need about 600-800 square meters.

2.Operation personnel quantity:

Artificial feeding: need 3-4 workers

3.Quarantee:

Overall quality assurance two years (except wearing parts under normal operation, free maintenance), life-long maintenance. Host the Q245R boiler steel plate, can bear high temperature 700 ℃.

♣ Material for waste tyre pyrolysis plant

1.Waste rubber tire, waste plastic, waste rubber products, etc.

2.Industrial mixed waste plastic, allowing dozens of waste existing at the same time (such as PP, PE, PVC mix together etc).

3.Waste oil:waste diesel, lube oil, engine oil, waste oil residue, mazut, tar oil, wax oil, waste crude oil etc.

4.Waste cable cover.

5.Waste PMMA(methyl methacrylate)rebirth.

6.Drainage oil, acid oil.

♣ Characteristics of waste tyre pyrolysis plant

1. High oil output rate 45%--55% with special catalyst formula and high tech.

2. Rapid condensers and large cooling area,assure you get much more and higher quality oil. diversiform cooling system (condensers or pipe pond) can be choose according to client's willingnes.

3. Dust-removing device -four levels dust processing system make sure no any population and the output smoking is the spray .more environmental protection. no-pollution.

4. Double tail-gas recycling and burning system, saving energy.

5. Q245R boiler plate, high temperature resistance, thickness reaches 16mm,guarantee

4-7 years service lives. and optional plate is Q345R.

Packing&Shipping of Waste tire/plastic pyrolysis plant for fuel oil

We can offer standard exporting packing for long distance sea transportation, wooden case with steel frame, it not only can protect machi Small hydraulic interlocking brick machine ne from damage, but also can guarantee smoothly pass the exporting inspection.

Looking forward to your inquiry