- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3phase 380V 50hz

-

Current:

-

Depands

-

Rated Capacity:

-

depands

-

Rated Duty Cycle:

-

60-100%

-

Dimensions:

-

Depands

-

Use:

-

Welding support

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

CE/CCC

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PCL

-

Weight (KG):

-

2000

-

Voltage:

-

3phase 380V 50hz

-

Current:

-

Depands

-

Rated Capacity:

-

depands

-

Rated Duty Cycle:

-

60-100%

-

Dimensions:

-

Depands

-

Use:

-

Welding support

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

CE/CCC

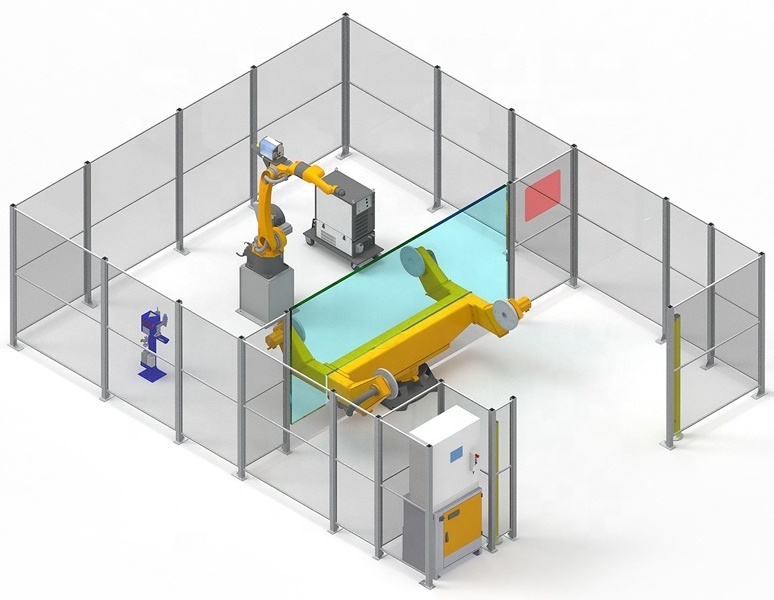

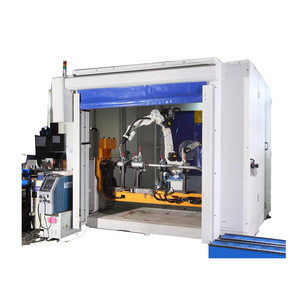

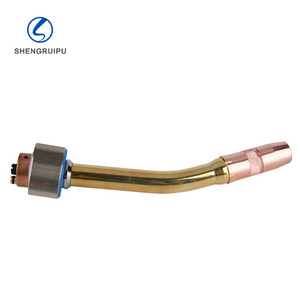

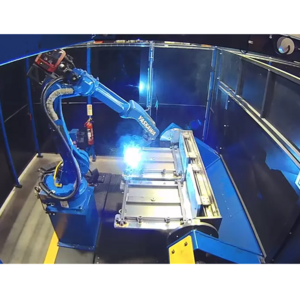

Welding robot consists of robot and welding device. The robot is made up of robot body and controller (hardware and software). While for the welding device, it is generally include welding source, control system, wire feeder(tig welding), welding gun(clamp), etc.

CNC automatic welding machine for space curve and space profiled curve welding.

Features: 1. The system also controls the four servo axes at the same time movement;

2. Arc starting arc time precise control;

3. Welding start position can be precisely controlled;

4. According to the product of any programming;

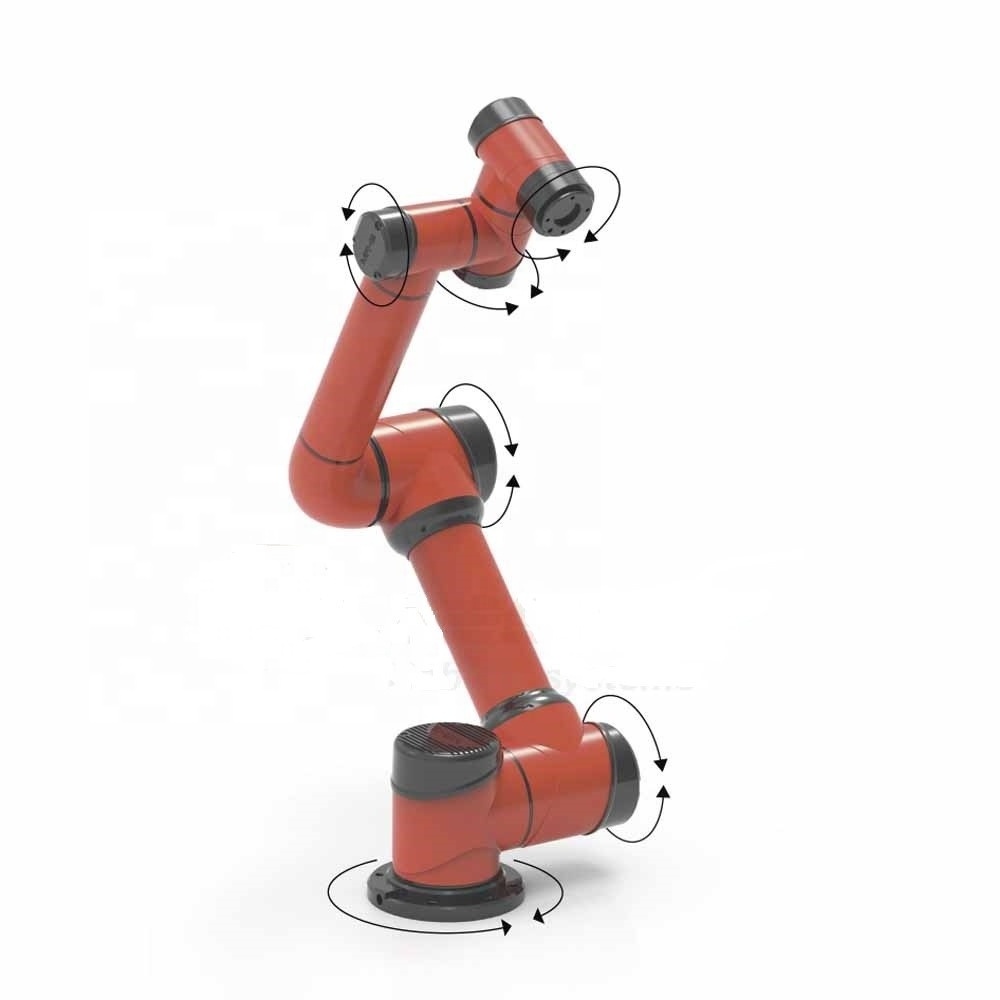

5. Weld uniform beautiful full. CNC Industrial Welding Robot / Robotic Arm 6 axis with Servo Motor 6 axis welding robot 4 axis welding robot

how a robotic arm welding machine typically works:

Robotic Arm: The robotic arm is the main component of the system. It consists of several articulated joints that allow the arm to move in multiple axes, mimicking the flexibility and range of motion of a human arm. The arm is controlled by a computer system, which sends commands to the arm's motors to position and orient it accurately.

Welding Equipment: The robotic arm is equipped with a welding tool, which may be a welding torch, a welding gun, or another welding device, depending on the specific application. The welding equipment is typically connected to a power source, gas supply, and wire feeder.

Programming: Before starting the welding operation, the robot needs to be programmed. This involves defining the weld path, specifying parameters such as welding speed, wire feed rate, and gas flow, and setting up any necessary sensors or vision systems for real-time feedback.

Welding Operation: Once programmed, the robotic arm welding machine can perform the welding operation. The robotic arm moves the welding tool along the predefined weld path, following the programmed parameters. It applies the necessary heat and filler material to join the workpieces together.

Sensors and Vision Systems: Some robotic welding systems incorporate sensors and vision systems to enhance accuracy and adaptability. These sensors can monitor the position and orientation of the workpieces, detect gaps or deviations, and adjust the welding process in real time to compensate for any variations.

Benefits of Robotic Arm Welding Machines:

- Increased Efficiency and Productivity: Robotic welding systems can work continuously without fatigue, resulting in increased productivity and reduced cycle times compared to manual welding.

- Improved Weld Quality: Robots can consistently perform precise and repeatable welds, minimizing errors and defects. This leads to improved weld quality and overall product consistency.

- Enhanced Safety: By automating the welding process, robotic arm welding machines help reduce the exposure of human operators to hazardous welding fumes, intense heat, and other safety risks.

- Cost Savings: While the initial investment in a robotic arm welding machine can be significant, it can result in long-term cost savings by reducing labor costs, minimizing rework and scrap, and optimizing material usage.

- Robotic arm welding machines are widely used in various industries, including automotive, aerospace, manufacturing, and construction, where welding is a common operation. They are suitable for a range of welding applications, such as spot welding, seam welding, arc welding, and more.

It's important to note that different manufacturers may offer different models and features for robotic arm welding machines. Therefore, it's recommended to consult specific machine documentation or reach out to manufacturers for detailed information regarding a particular system's capabilities and specifications.