- Product Details

- {{item.text}}

Quick Details

-

Welding Mode:

-

Dock

-

Welding Diameter:

-

80-1000mm

-

Dimensions:

-

3130*1530*1600

-

Use:

-

Tank Welding

-

Voltage:

-

customized

-

Weight (KG):

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

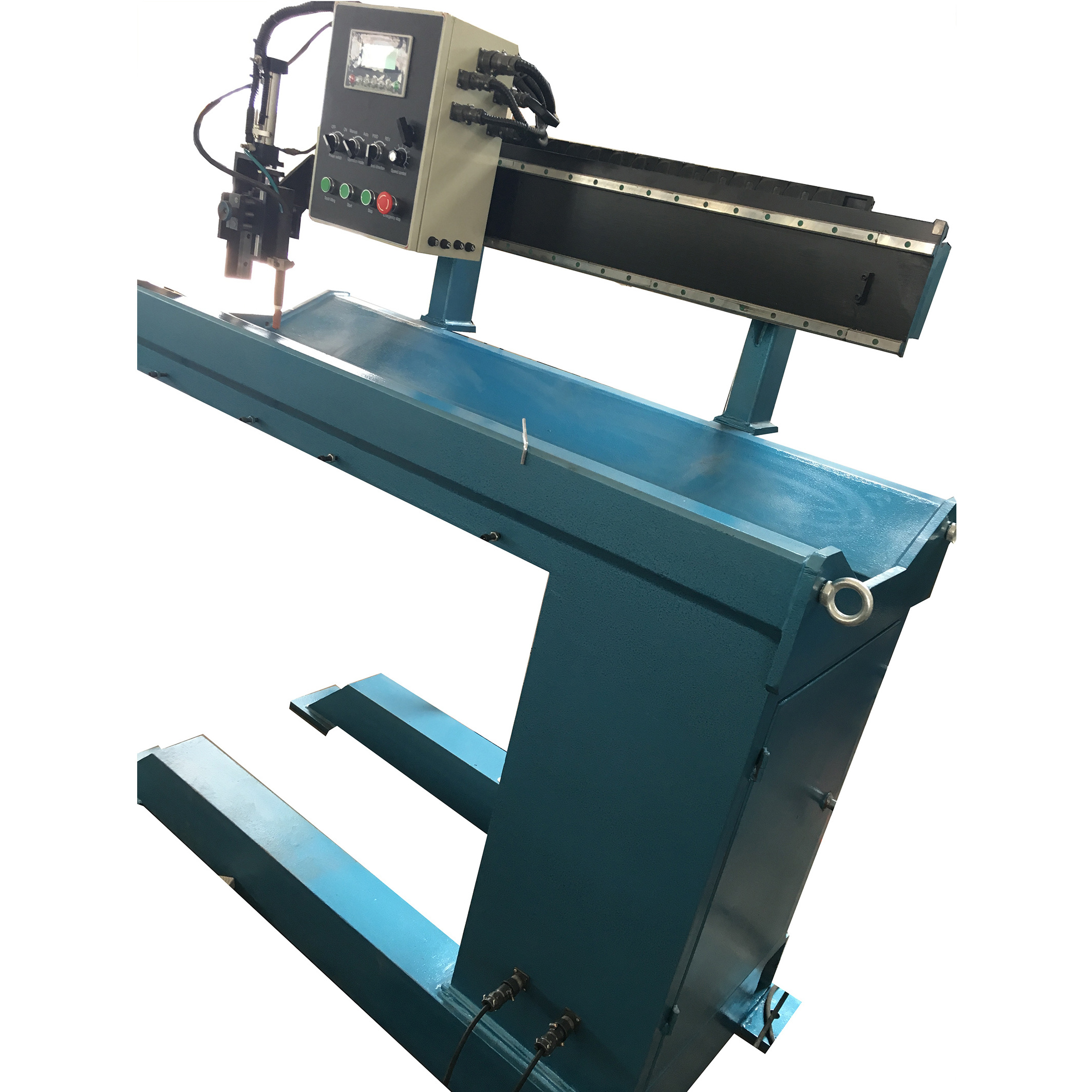

Horizontal TIG/MIG Automatic flat sheet seam welding machine for tank

-

Welding Speed:

-

100-2500 mm/min

-

Application:

-

tank welding

-

Welding material:

-

ss carbon steel

-

Thickness:

-

6mm maxium

-

Arm length:

-

1000mm

-

port:

-

shanghai

-

Color:

-

upon requestment

-

Control Panel:

-

english version

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Metform

-

Forming Time:

-

2S

-

Welding Mode:

-

Dock

-

Welding Diameter:

-

80-1000mm

-

Dimensions:

-

3130*1530*1600

-

Use:

-

Tank Welding

-

Voltage:

-

customized

-

Weight (KG):

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Horizontal TIG/MIG Automatic flat sheet seam welding machine for tank

-

Welding Speed:

-

100-2500 mm/min

-

Application:

-

tank welding

-

Welding material:

-

ss carbon steel

-

Thickness:

-

6mm maxium

-

Arm length:

-

1000mm

-

port:

-

shanghai

-

Color:

-

upon requestment

-

Control Panel:

-

english version

Products Description

|

Model No.

|

ZF-1000

|

ZF-1500

|

ZF-2000

|

ZF-2500

|

|||

|

Welding length(mm)

|

1000

|

1500

|

2000

|

2500

|

|||

|

Min. diameter(mm)

|

φ100

|

φ120

|

φ160

|

φ200

|

|||

|

Max diameter(mm)

|

φ1000

|

φ1000

|

φ1000

|

φ1000

|

|||

|

Welding thickness

|

0.8-6mm

|

0.8-6mm

|

0.8-6mm

|

0.8-6mm

|

|||

|

Welding speed

|

150-1500 mm/min

|

|

|

|

|||

|

Speed control

|

Stepless speed control

|

|

|

|

|||

|

Transmission mode

|

Guide rail+gear and rack

|

|

|

|

|||

Main Frame

Frame welded structure to meet the stability of equipment for long-term use. The base can be fixed with a foot screw.

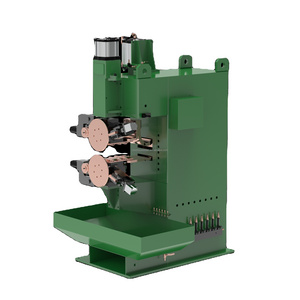

Pneumatic clamping device

The key-pressing mechanism provides uniform and stable working clamping and cooling. The workpiece is uniformly deformed by force.Provides a reliable guarantee for high quality, efficient and distortion-free welding of thin-walled workpieces.

Mandrel

It can meet the welding needs of different plate thicknesses,pipe diameter.

Operation panel

Multiple languages are optional and easy to operate.

Back gas protection

The back process of the welding process protects the air from reacting with the air to ensure the beautiful appearance of the

weld.

weld.

Products Application

Why Choose Us

Hot Searches