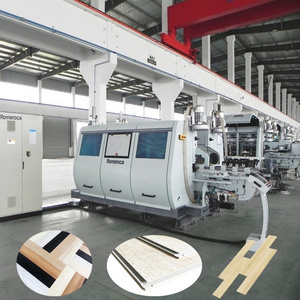

1,High equipment DTH : heary-duty equipment,more stable,convenient,advanced

2,it is mainly used in the forming processing of plate's short side. .Max.working width standard have 1500mm and 2500mm.The other requires can make to order.

- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Overseas service center available, Online support

-

main color:

-

grey

-

warning color:

-

yellow

-

Max.working width standard:

-

1500mm and 2500mm

-

rotate speed of cutter shaft:

-

6000-7000

-

Max.insert depth:

-

5/7/12(17) feeding speed adjustable to cutter volume

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

hotjin

-

Weight (KG):

-

15000 KG

-

After-sales Service Provided:

-

Overseas service center available, Online support

-

main color:

-

grey

-

warning color:

-

yellow

-

Max.working width standard:

-

1500mm and 2500mm

-

rotate speed of cutter shaft:

-

6000-7000

-

Max.insert depth:

-

5/7/12(17) feeding speed adjustable to cutter volume

Transverse double end tenoner(Model: DTH6/18/10D+2G)

Function

:DTE series machine, it used in the forming processing of board's two short sides, it uses six stations, install 10 shafts, has a space station for scraper system.

Basic configuration:

1.Double chain,straightness precision is 0.02mm;Lead rail main body use alloy material, hardness about 650;

2.Two chain are bearing rolling,error of pitch is 0.005mm,the whole line accumulative error less than 0.1mm;

3.Upper press with manual adjustable to meet corresponding floor thickness, it use D and V belt passive compress;

4.In the front of have feed bin, photoelectric control, feed bin max. stacking height 150mm, one side can adjust fixed running rule, one side can adjust elasticity blind after feed bin, to ensure the board left and right position. Feed bin max.width can achieve 650mm;

5.Between two feeding chain have a support table, can ensure board leveling when cutting, the support table is knockdown, make sure different working size.

6.Have blower system in chain, make sure chain inside positive pressure, reduce dust into;

7.pusher of feeding chain standard pitch is 400 (600) mm, the pusher more than chain pad size decide to customer's working thickness

8.The tool tip under slider uses carbide material, wear resistance;

9.The tool tip upper press carbide material use air pressure to bring steady pressure, the air pressure can adjust;

8. Have 5 motors in each side, each station has a Dia. 120mm dust hood; it has 2 sets scraper system, and all have filter box, after scrape stripe will not be suck into dust pipe

9. Under each cutter shaft have a dust hood inside machine body, it can suck omissive dust again

10. The cutter shaft use T lead screw adjust, show distance on the numerical indicator, have dialgage delicate adjusting, the precision can achieve to 0.01mm.;

11.Adjust angle of cutter shaft by turbine worm system, it use screw rotate can 3600 adjust, easy to use;

12.The equipment have noise enclosure, inside has noise cotton; Have rings on the top of machine, can hoisting entirety.

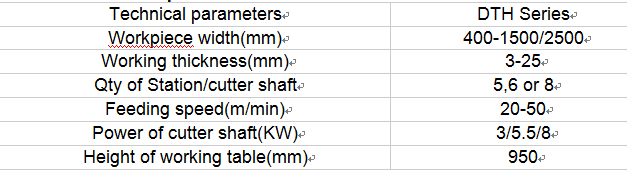

Parameter of the main machine:

1.Working width:600-1800 mm

2.Working thickness: 4-15 mm

3.Height of working table: 950 mm

4.Rotate speed of cutter shaft: 6000-7000 rpm

5.Feeding speed:20-40 m/min

6.Motor power of cutter shaft:(Inverter control)

The 1st station power (each left and right):5.5 kw precutter,+45°,up milling Φ250

The 2nd station power (each left and right):5.5kw precutter,-45°,up milling Φ250

The 3rd station power (each left and right):3kw profile-cutter,+90°,up milling Φ250

The 4th station power (each left and right):space (can install scraper system)

The 5th station power (each left and right):5.5kw finish-cutter,+90°,up milling Φ250

The 6th station power (each left and right):3kw click-cutter,+(-)45°(22.5°),up milling Φ250

7.Feeding motor power: 4 kw(Inverter control)

Blower motor power:2.2kw X2

Width adjusting motor: 1.1kw

8.Cutter diameter: Φ220-250XΦ40

About cutter we suggest use hydraulic system , the other motor need to notes specially.

9.Dust hood diameter

Station 1st 2nd 3rd 4th 5th 6th :Φ120mmX12

Machine cover diameter:120mmX2

10.Weight:9500 Kg

The main technical parameters

Pre-sale

●Provide the information in time at customer requirement and make reasonable proposals and budgeting

●Give technical support for the customer's renovation of old facilities for free

●Provide service and support to the customer's other equipments

In-sale

●On-site planning for the customers by professional engineer

●Valuable advice and recommendations on the purchasing of other auxiliary accessories

●Free training for operators

Name:SUZHOU HOTJIN PRECISION MACHINERY CO.,LTD

Add:58 Pusha rd.,Puzhuang Industrial Park ,Wuzhong District,Suzhou city, Jiangsu province, China.

Tel:+86-512-66520585

Fax:+86-512-66520585

Post code:215105

https://szhotjin.en.alibaba.com/?spm=a2700.details.cordpanyb.1.4ba86669hEU3LD