- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SiCheng Abrasives

-

Model Number:

-

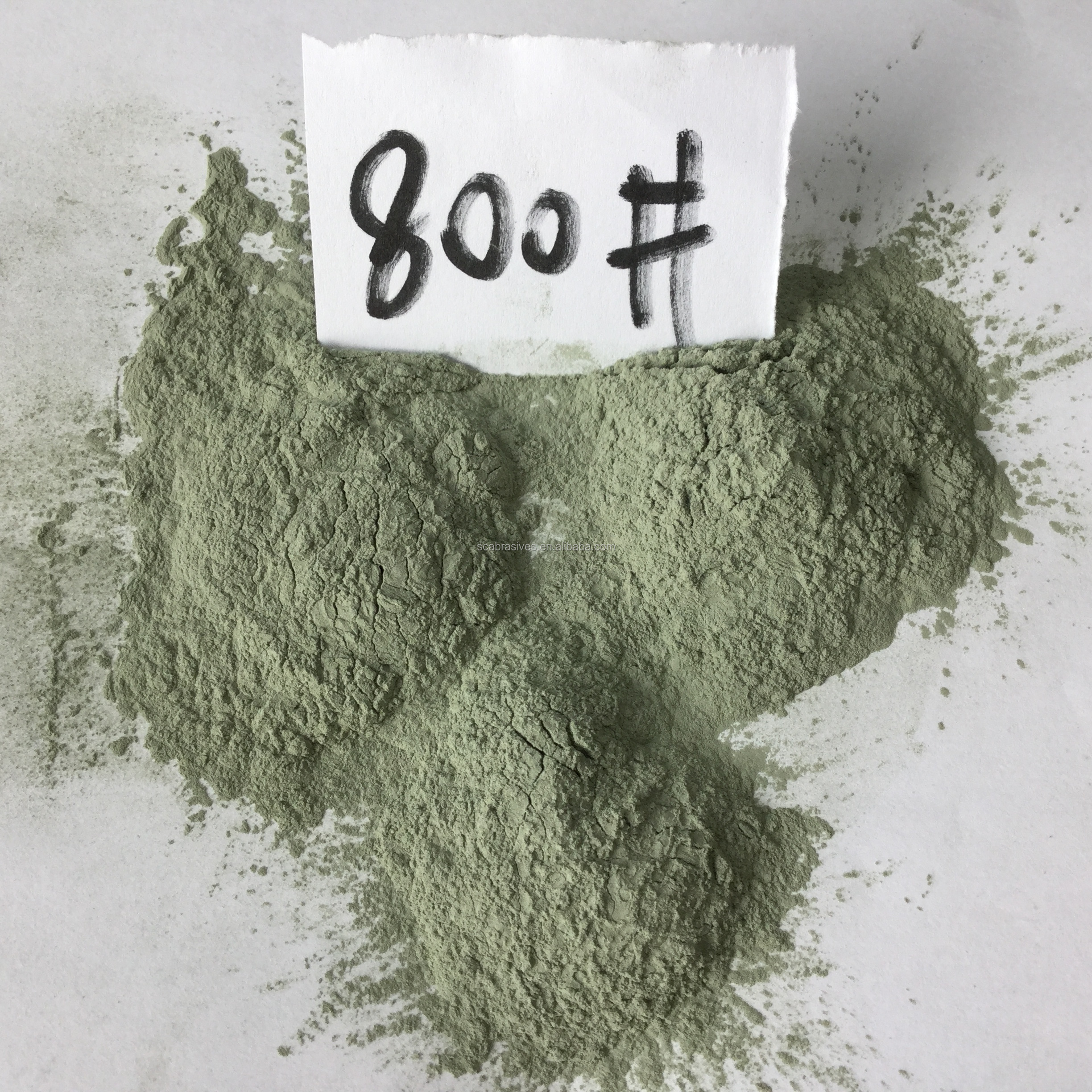

240 280 320 400 500 600 800 1000

-

Use:

-

Marble polishing

-

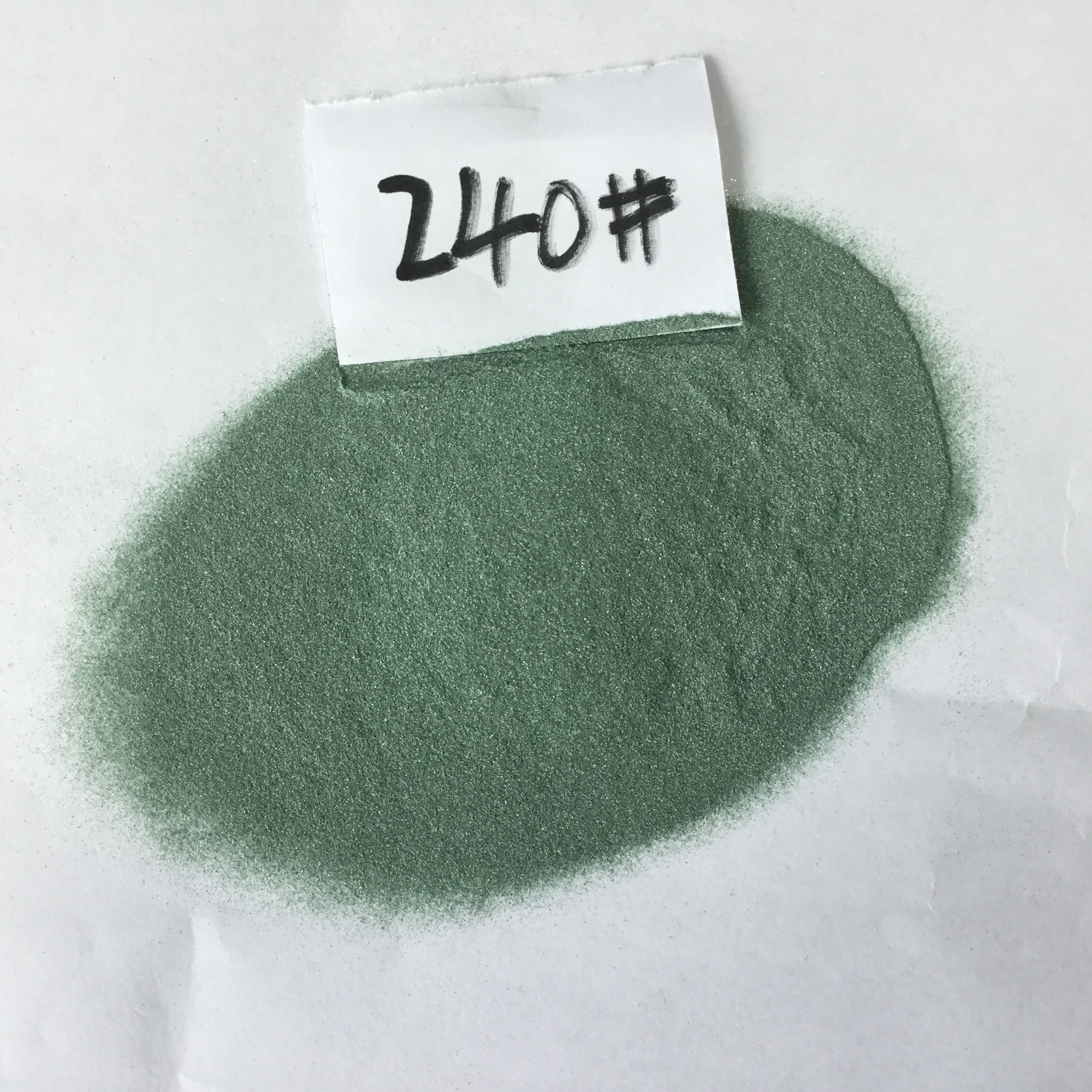

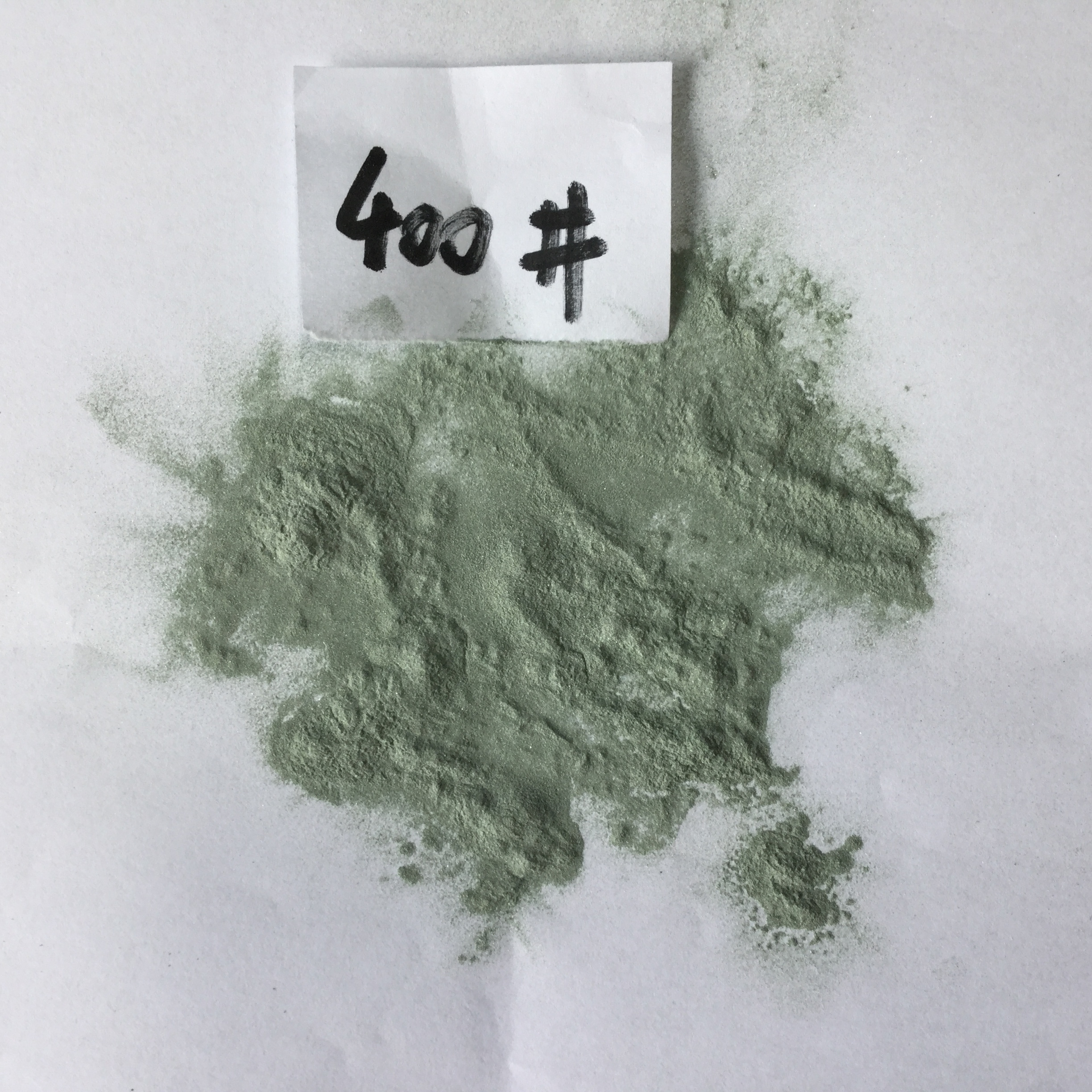

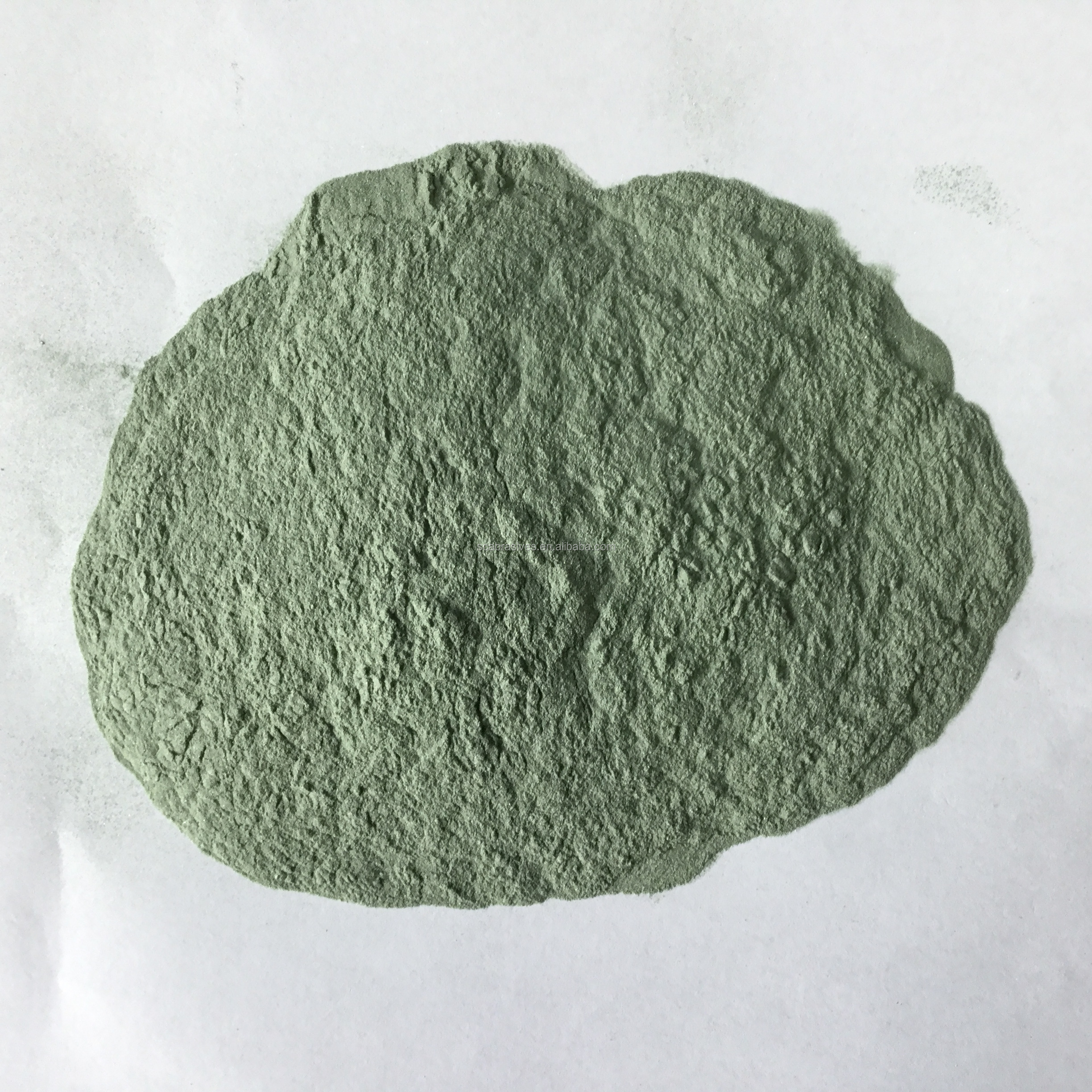

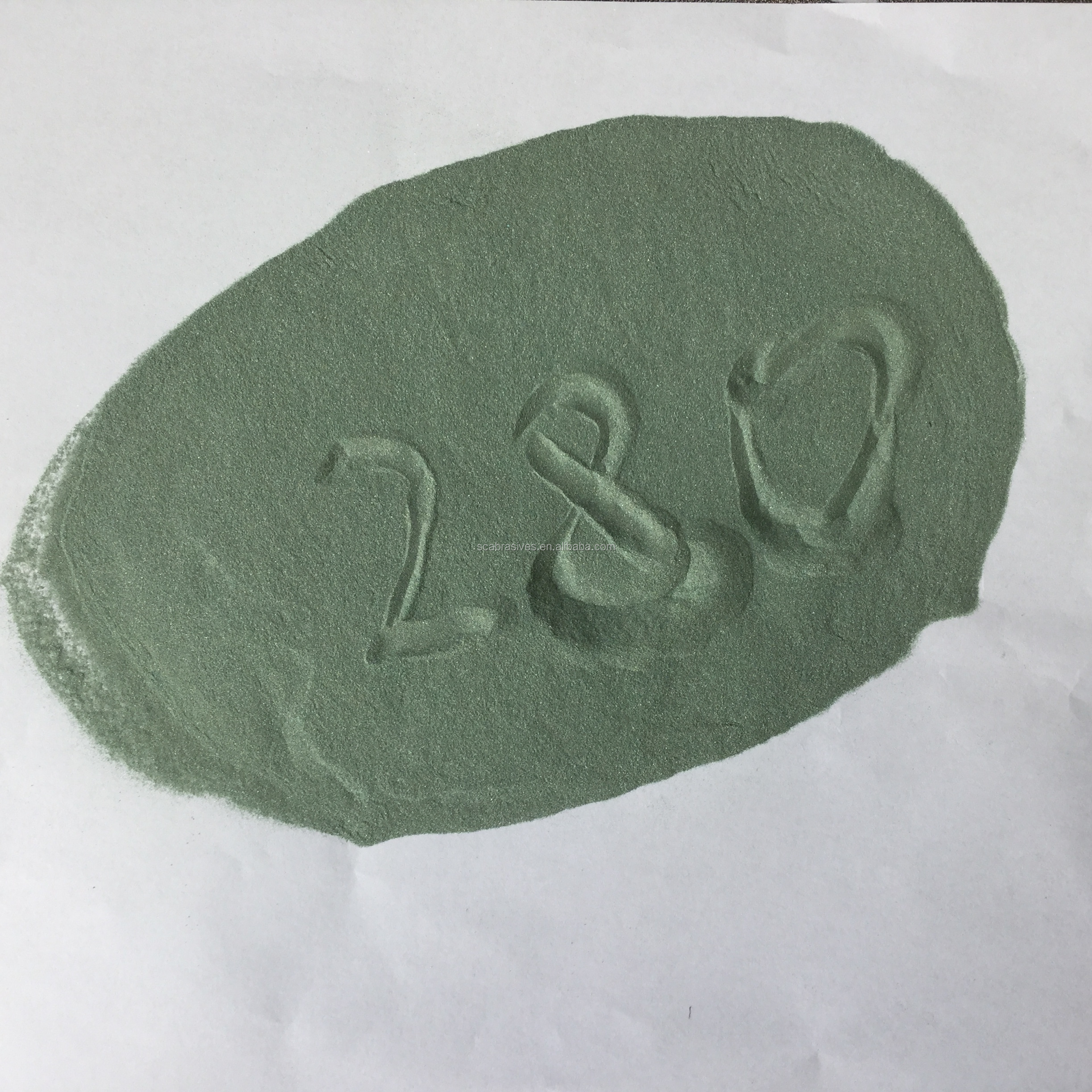

Color:

-

Green

-

Specific Gravity:

-

3.2g/cm3

-

Mohs Hardness:

-

9.4

-

Bulk density:

-

1.2-1.6g/cm3

-

Material:

-

99%SIC

-

Sample:

-

Sample Provided

-

Melting Point:

-

2250℃

-

Real Density:

-

3.90g/cm3

-

Certificate:

-

ISO9001:2008

Quick Details

-

Type:

-

blasting media, polishing powder

-

Abrasive Grain Sizes:

-

240 280 320 400 500 600 800 1000, 240 280 320 400 500 600 800 1000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SiCheng Abrasives

-

Model Number:

-

240 280 320 400 500 600 800 1000

-

Use:

-

Marble polishing

-

Color:

-

Green

-

Specific Gravity:

-

3.2g/cm3

-

Mohs Hardness:

-

9.4

-

Bulk density:

-

1.2-1.6g/cm3

-

Material:

-

99%SIC

-

Sample:

-

Sample Provided

-

Melting Point:

-

2250℃

-

Real Density:

-

3.90g/cm3

-

Certificate:

-

ISO9001:2008

Marble polishing powder Green silicon carbide powder for marble stone polishing

|

Description of items |

BLACK/GREEN SILICON CARBIDE |

||

|

SiC |

98.5-99.4% |

||

|

Fe2O3 |

0.05-0.10% |

||

|

F.C |

0.06-0.15% |

||

|

Melting point(℃) |

2250 |

||

|

Maximum service temperature (℃) |

1900 |

||

|

Specific Gravity |

3.90g/cm3 |

||

|

Mohs Hardness |

9.15-9.5 |

||

|

Production Sizes |

GRIT |

JIS |

#16 #20 #24 #30 #36 #46 #54 #60 #70 #80 #90 #100 #120 #150 #180 #220 |

|

FEPA |

F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 |

||

|

Powder |

JIS |

#240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000 #2500 #3000 #4000 #6000 |

|

|

FEPA |

F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 |

||

Green silicon carbide powder

for

Bonded & Industrial Abrasives

Green Silicon Carbide powder for

Coated Abrasives

Green Silicon Carbide powder for

Ceramics