- Product Details

- {{item.text}}

Quick Details

-

MF:

-

(C3H6)n

-

EINECS No.:

-

/

-

Place of Origin:

-

Jiangsu, China

-

Type:

-

Micronized PP Wax Additive

-

Brand Name:

-

Tianshi

-

Model Number:

-

PPW-0901

-

Trade Name:

-

Polypropylene Wax

-

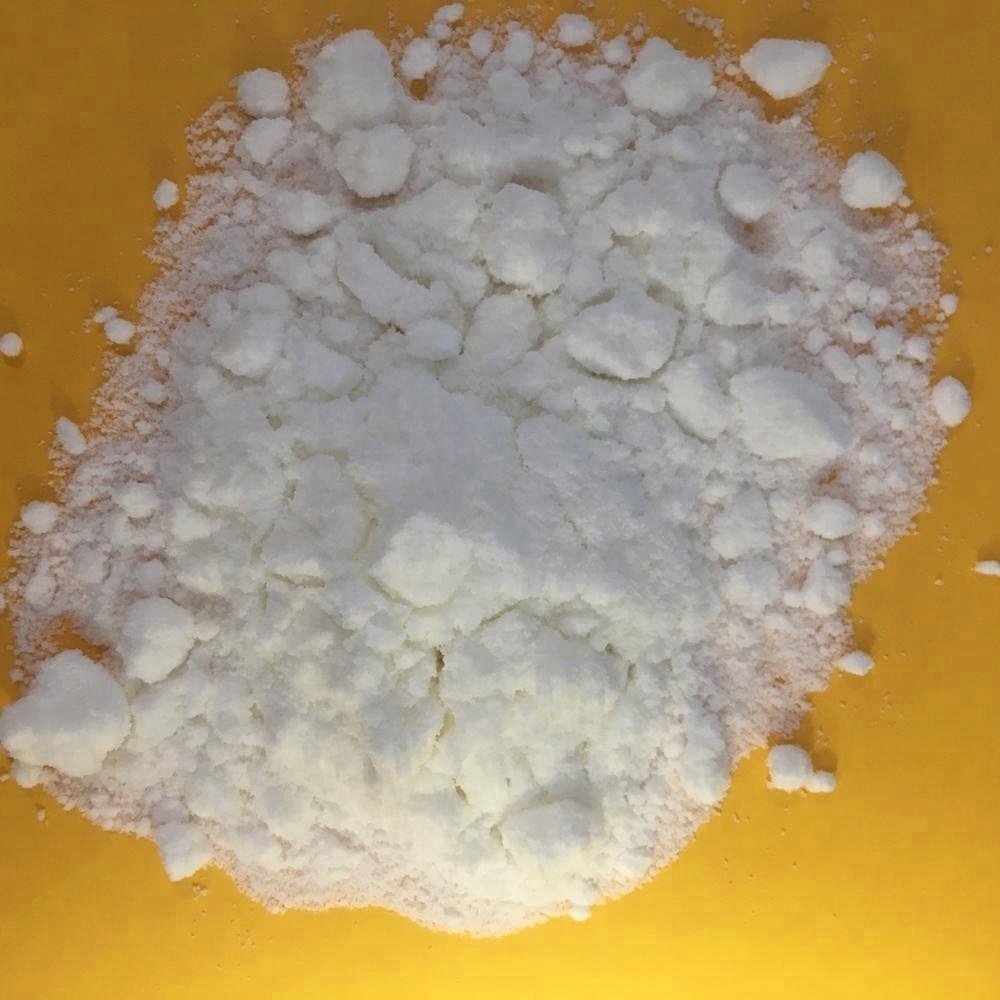

Appearance:

-

White Powder

-

Typical Properties:

-

High melting point, high hardness, and can be easily dispersed

-

Keywords:

-

Polypropylene Wax Additives

-

Shelf Life:

-

24 Months

Quick Details

-

CAS No.:

-

68649-51-1

-

Purity:

-

100%

-

Other Names:

-

Polypropylene Wax

-

MF:

-

(C3H6)n

-

EINECS No.:

-

/

-

Place of Origin:

-

Jiangsu, China

-

Type:

-

Micronized PP Wax Additive

-

Brand Name:

-

Tianshi

-

Model Number:

-

PPW-0901

-

Trade Name:

-

Polypropylene Wax

-

Appearance:

-

White Powder

-

Typical Properties:

-

High melting point, high hardness, and can be easily dispersed

-

Keywords:

-

Polypropylene Wax Additives

-

Shelf Life:

-

24 Months

Polypropylene Wax Additives

micronized polypropylene wax usually have highe melt point and hardness. Micronized PP waxes can improve the performance of abrasion and anti blocking, when added into painting or inks and powder coating. Different p

oly

propylene wax can usually used as matting agent, degassing agent, anti-slip, anti-adhesion, hardening agent etc.

PPW-0901

Polypropylene Wax

Chemical Composition

Polypropylene wax

Technical Parameters

|

Nature of the Product |

PPW-0901 |

|

|

Appearance |

|

White Powder |

|

Particle size μm |

|

|

|

|

Dv50 |

6-8 |

|

|

Dv90 |

14 |

|

Melting point ℃ |

|

145 |

Characteristics and Purposes

Ø PPW-0901 has uniform particle size and shape, good transparency, high melting point, high hardness, and can be easily dispersed. It is suitable for solvent-based inks and coatings. It helps improve scratch resistance, and high temperature blocking resistance.

Ø PPW-0901 can be used in powder coating. It helps improve powder coating hardness, scratch resistance, increases wear resistance, and at the same time assists in matting.

Contents and Methods of Use

Ø In a variety of systems, the additional amount of the wax powder is generally between 0.5 to 3%.

Ø Usually by the way of direct high-speed stirring, it dispersed in solvent-based coatings and printing inks.

Ø It can be added through the use of variety of grinding machines, high-shear dispersing device, and the use of grind mill. Must pay attention to the control of the temperature.Can carry out the decentralized processing to make the wax slurry with the wax powder concentration at 20-30%., then add it into the systems when needed, which can decrease the dispersion time.

Paper-plastic bag, net weight: 20 kg / bag, 400kg/pallet, 8000kg/20GP;

Delivery:3-7days after payment received;

Hazards

The product is non-dangerous and does not require a hazard warning label according CLP regulation.

For further information please refer to the Material Safety Data Sheet.

Contact Us

Please

contact us

for safety and regulatory details or the Material Safety Data Sheet (MSDS).