- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

rebar bender

-

Type:

-

CNC

-

Application:

-

Large construction project

-

Bending material:

-

wire,iron bar

-

Voltage:

-

380V/415V

-

Machine Type:

-

Steel Bar Bending Machine

-

Power:

-

21KW

-

Keyword:

-

CNC Wire Bending Machine

-

Max bending speed:

-

1840pics/h

-

Bending range:

-

4-30mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUC

-

Weight (KG):

-

2550

-

Product name:

-

rebar bender

-

Type:

-

CNC

-

Application:

-

Large construction project

-

Bending material:

-

wire,iron bar

-

Voltage:

-

380V/415V

-

Machine Type:

-

Steel Bar Bending Machine

-

Power:

-

21KW

-

Keyword:

-

CNC Wire Bending Machine

-

Max bending speed:

-

1840pics/h

-

Bending range:

-

4-30mm

Gtd4-10 automatic used rebar stirrup bending machine/rebar bender

CNC stirrup bender machine controlled by servo system, can automatically accomplish elastic, straighten , stirrup bending, cutting and so on.

Application : Widely used in construction industry and rebar manufacturing enterprise; for steel wire rod, steel bar, steel rebar, etc.

Automatic stirrup bender machine used in construction site

The technical parameter of GTW8-16 CNC AUTOMATIC Stirrup bending machine

|

Production capacity |

Single Wire Diameter:8-16mm Double Wire Diameter:8-12mm |

|

Max.Bending Angle |

180° |

|

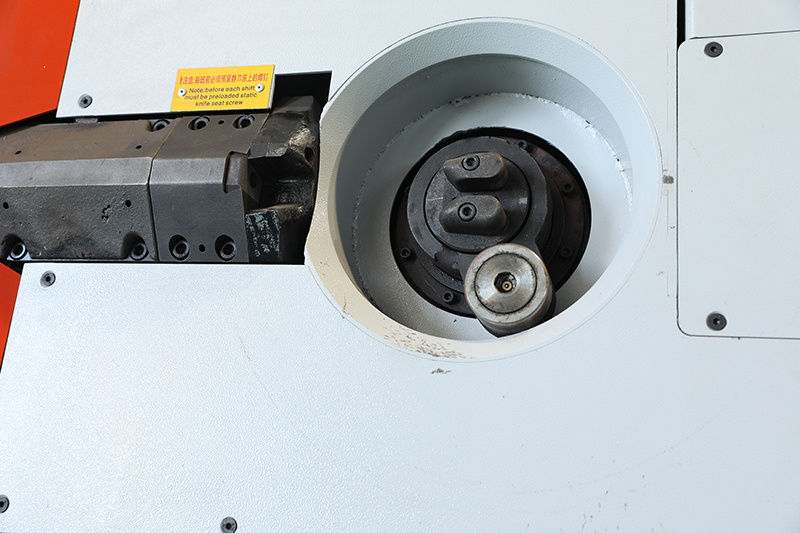

Central Mandrel Diameter |

φ20-30mm |

|

Max.Pulling Speed |

110m/min |

|

Max.Bending Speed |

1100pics/h |

|

Average Electric Power Consumption |

5kw/h |

|

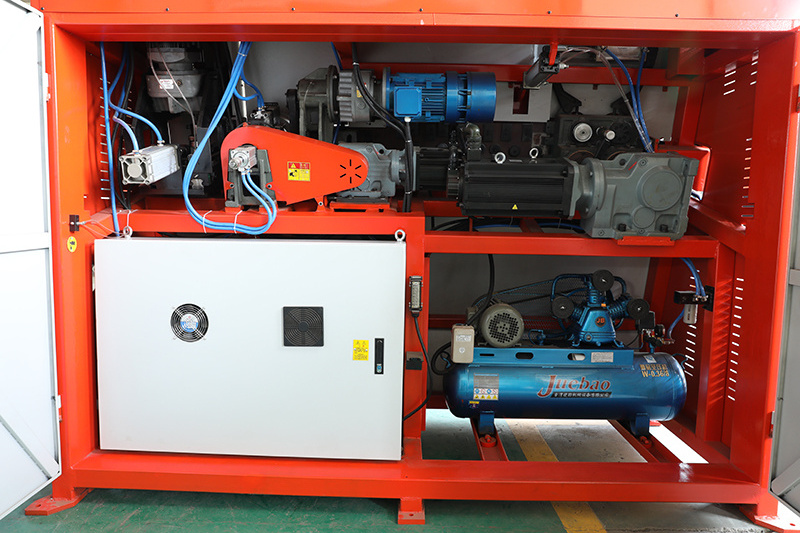

Rated Power 3 Servo Motor |

27kw+16.5kw+2.3KW |

|

1 Brake motor |

4kw |

|

1 motor for air pump |

4kw |

|

Voltage |

380V |

|

Working Environment Temperature |

-5~40 |

|

Overall Size |

3500*900*2150 |

|

Gross Weight |

2.89T |

Specifications:

1.Automatic wire feeding system ( CNC ).

2. Moveable air compressor design , to ensure better cooling effect, easy transportation and installation

3. Split, multi-blade design (patented) to reduce consumption costs

4.Large storage capacity can save 500 processing geometric graphics , high degree automation

5.Automatic double wire intake system , high processing efficiency

6. High power feeding motor to ensure bending bar accuracy.

7.The intelligent fault identifica tion alarm system maintenance more convenient

8. Aerodynamic design observation door, easy adjustment and maintenance, and more security and fast.

9.Heavy-duty design line planes, equipped with a brake and buffer device can prevent chaotic lines caused by downtime

10. High quality special material and high treatment to make straightening wheels, traction wheels, the metering wheel, longer life with lower operating costs

11. Touch-screen console , easy to operate, and more fast

12. Control systems: SIEMENS, MITSUBISHI, and YASKAWA SCHNEIDER

Product show:

The Feeder system, traction wheels and straightening wheel

Machine Installation in Lebanon

Company information

Our company, Changge yufa Machinery Manufacturing Co., established in 1996, is a professional manufacturer

of rebar cutter, rebar bender, CNC wire straightening and cutting machine, CNC stirrup bender, plate compactor,

vibration tamping rammer, power trowel and so on. Its 18 years since we set up our factory, our products have been

used widely in many coutries and areas such as India, Sri Lanka, Pakistan, Combodia, Indonesia, Malaysia, Tunisia,

Algeria, Canada, New Zealand, Hongkong and so on.

Yu Chuang today is a company of more than 300 employees, 20,000 square meters production area and more than

100 outlets scattered in Asia, Austrilia, Middle East, South America and Africa.

CARTON FAIR :

Why choose us?

1We are the manufacturer which has produced these machines for almost 20 years,you can get the machine from us directly rather than through other trading company,so you can save a lot of money.

2.We have two years warrently compare with others only one year.

3.100% QC inspection before Shippment;

4.ISO/SGS/3C Listed,competitve price.

Payment Terms:

1.Payment: T/T, Western Union; 30% deposits; 70% balance before delivery

2. MOQ: 1pcs;

How to Contact Us?

Send your Inquiry Details in the Below, Click "Send" Now!!